Synthesis method of SSZ-13 zeolite

A synthesis method and zeolite technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of toxicity, environmental damage, high price, etc., and achieve the effect of low toxicity, low price, and wide range of silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following ratio is an example to illustrate the preparation process of the present invention

[0028] raw material:

[0029] Silica sol: SiO 2 30.24%, Na 2 O 0.212%

[0030] Aluminum sulfate:Al 2 (SO 4 ) 3 18H 2 o

[0031] NaOH

[0032] Herotropine

[0033] h 2 o

[0034] Reactant molar ratio: SAR=40; OH - / SiO 2 =0.8; R / SiO 2 =0.25;H 2 O / SiO 2 =22.5.

[0035]

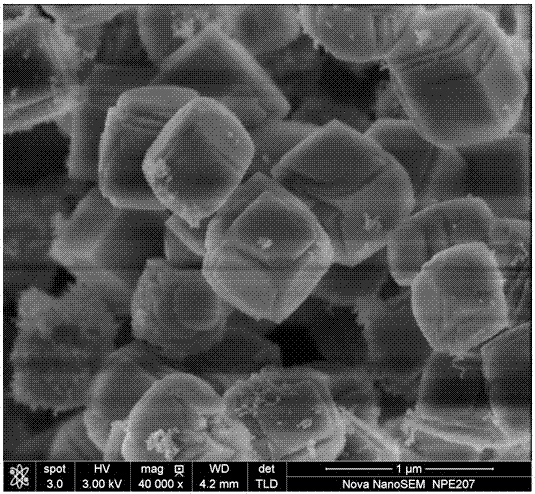

[0036] According to this formula, the raw materials were weighed and mixed, stirred vigorously to form a colloid, and then placed in a stainless steel reactor with a capacity of 100ml for a hydrothermal reaction at 180°C for 60 hours to generate SSZ-13 zeolite crystals. The product was cooled, filtered, washed with deionized water, Filter and dry to obtain the target product.

[0037] The following table lists the reactant molar ratio, reaction temperature and time, the SAR of the product, and its BET surface area, micropore surface area, total pore volume, micropore volume, average por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com