Preparation method of SSZ-13 hydrogen type molecular sieve, and preparation method of SCR catalyst

A technology of hydrogen-type molecular sieve and ammonium hydroxide, which is applied in the field of catalysis, can solve the problems of high cost, narrow operating temperature window, poor selection of low-temperature section, etc., and achieve the effects of reduced production cost, saved preparation time, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

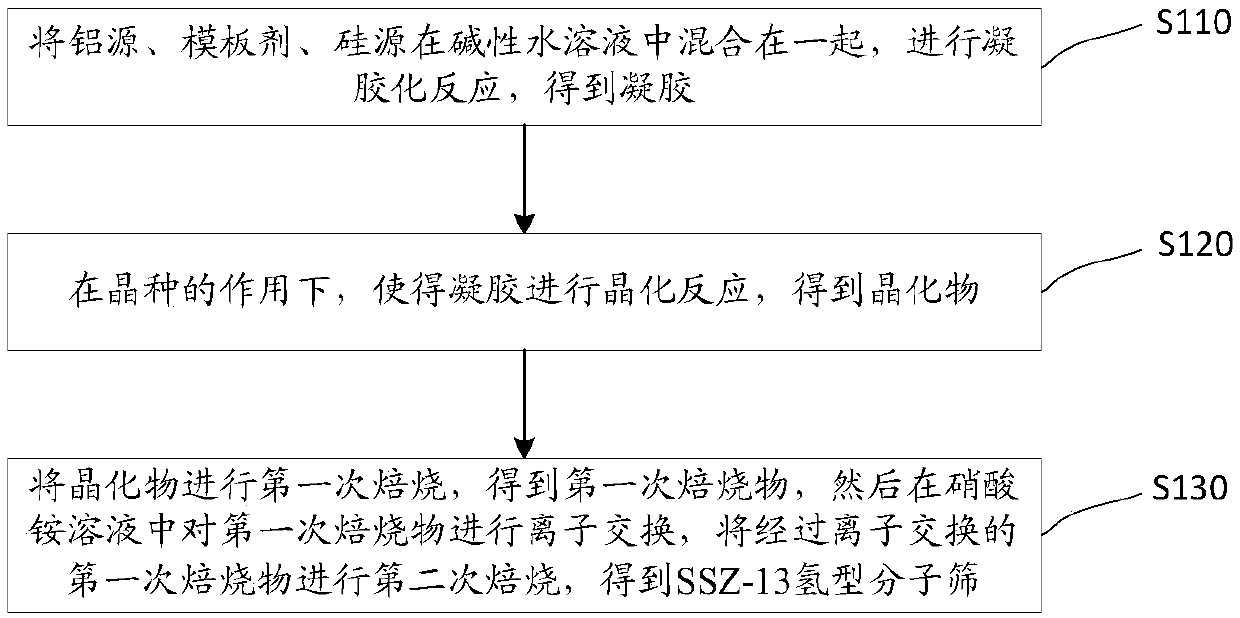

[0034] see figure 1 , the preparation method of the SSZ-13 hydrogen molecular sieve provided by the embodiment of the present invention comprises:

[0035] Step S110: mixing the aluminum source, the template agent, and the silicon source together in an alkaline aqueous solution, and performing a gelation reaction to obtain a gel;

[0036] Step S120: Under the action of the seed crystal, the gel undergoes a crystallization reaction to obtain a crystallized product;

[0037] Step S130: Carry out the first roasting of the crystallized product to obtain the first roasted product, then perform ion exchange on the first roasted product in an ammonium salt solution, and perform a second roasting on the ion-exchanged first roasted product , to obtain SSZ-13 hydrogen molecular sieve.

[0038] In the preparation method of the SSZ-13 hydrogen molecular sieve provided based on the above-mentioned examples, the aluminum source, template agent, and silicon source that are relatively easy ...

Embodiment 1

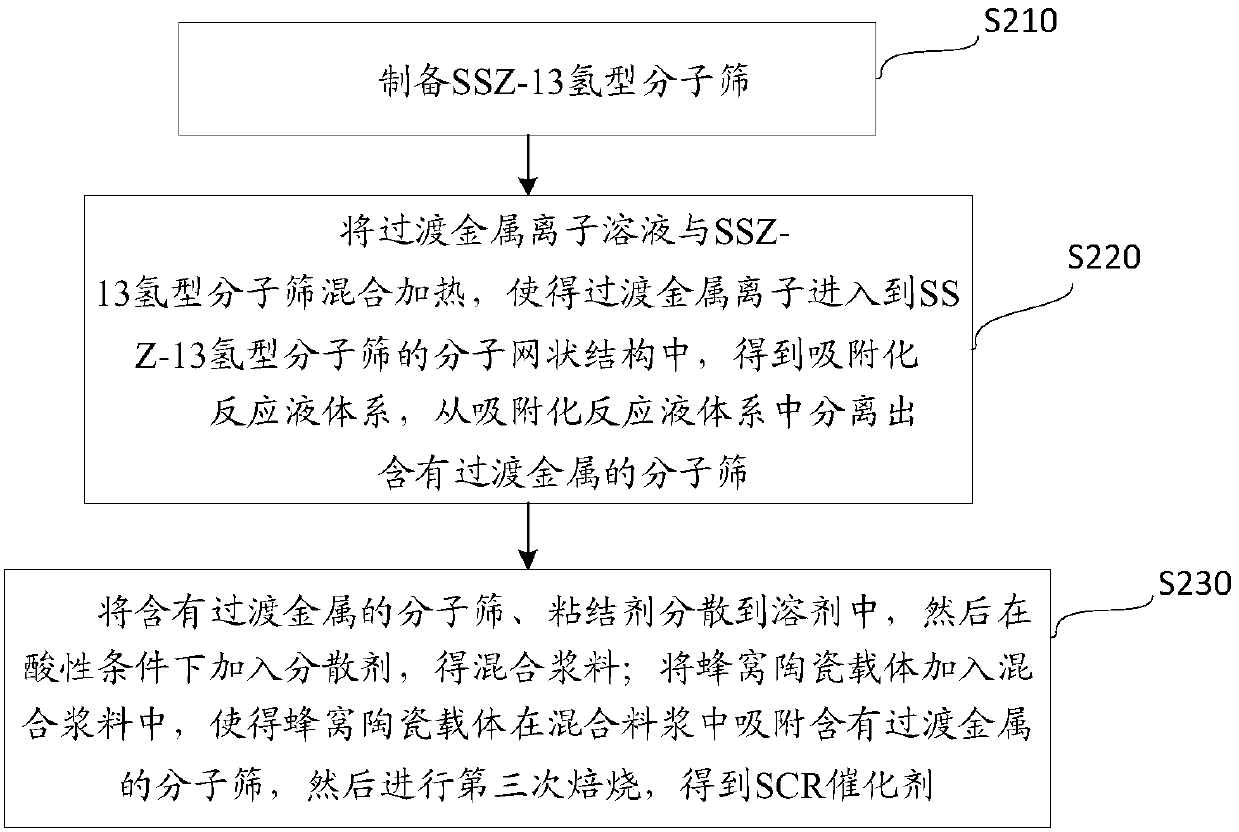

[0073] The present embodiment provides a kind of preparation method of SCR catalyst, comprises the following steps:

[0074] Step S210: Prepare SSZ-13 hydrogen molecular sieve by the following method; the specific method includes the following steps:

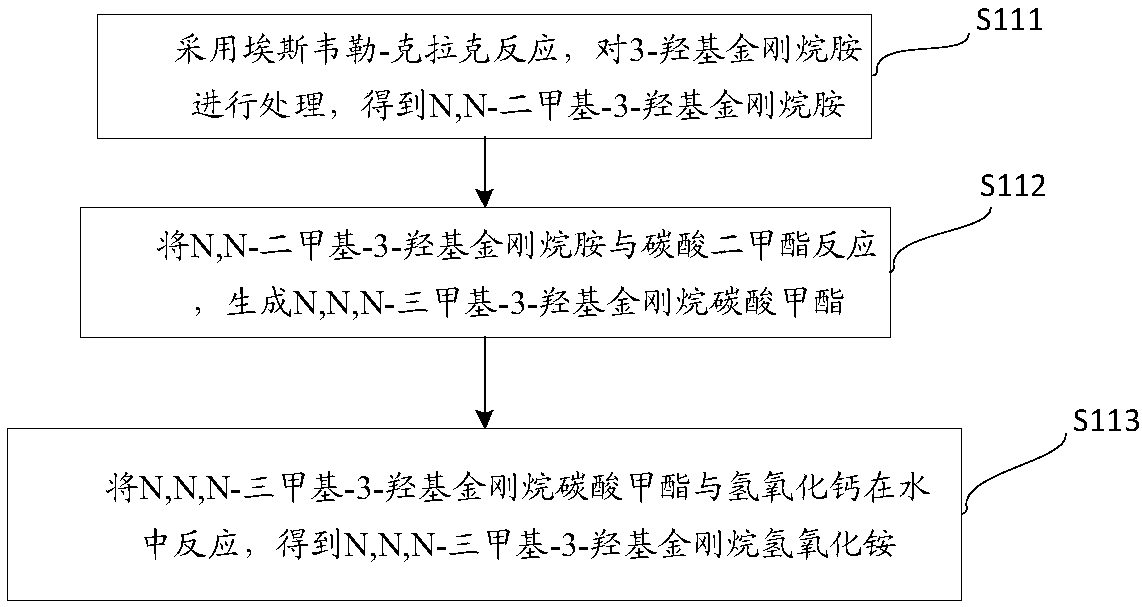

[0075]Step S111: At room temperature, sequentially add 890.8g of 3-hydroxyadamantanamine and 856.5g of anhydrous formic acid into a 10L reactor, and perform mechanical stirring for 0.5h, start to heat up to 80°C, and 1380.32g of formaldehyde solution (mass concentration is 37% %) was added dropwise under the condition of ℃, and the dropping time was 3h, then the temperature was raised to 98°C, and after the insulation reaction for 5h, the Esweiler-Clark reaction system was obtained; 3-hydroxyadamantine The molar ratio of formaldehyde in alkylamine, anhydrous formic acid and formaldehyde solution is 1:3.5:3.2;

[0076] The Esweiler-Clark reaction system was down to room temperature, and then aqueous sodium hydroxide solution (41...

Embodiment 3

[0098] Step S210: Prepare SSZ-13 hydrogen-type molecular sieves by the following method: step S111-step S113. For the specific method, refer to Example 1.

[0099] Step S114: Add KOH and Al to the Erlenmeyer flask at room temperature 2 (SO 4 ) 3 .18H 2 O, the aqueous solution containing N,N,N-trimethyl-3-hydroxyadamantyl ammonium hydroxide (mass concentration is 25.4%), benzyl trimethyl ammonium hydroxide and deionized water, stirred at room temperature for 1h to dissolve, and then Silica sol was added dropwise for 10 minutes, followed by stirring at 30°C for 2 hours to form a gel; among them, N,N,N-trimethyl-3-hydroxyadamantyl ammonium hydroxide, benzyltrimethylammonium hydroxide and silica sol The molar ratio of silicon is 0.036:0.014:1, silicon and Al in silica sol 2 (SO 4 ) 3 .18H 2 The molar ratio of aluminum in O is 10:1, and the molar ratio of potassium hydroxide to silicon in silica sol is 0.45:1.

[0100] Step S120: Move the gel into the hydrothermal reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com