Freeze-dried preparation moisture control method and application thereof

A control method and technology of freeze-dried preparations, which can be used in freeze-dried transportation, drying, and pharmaceutical formulations. It can solve problems such as large quality changes, high product moisture, and short expiration dates, and achieve high purity, improved sublimation drying speed, and expiration dates. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

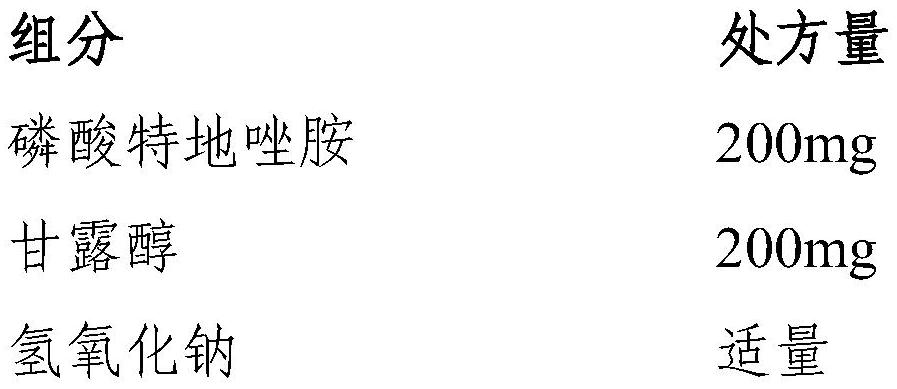

[0034] Embodiment 1 tedizolid phosphate for injection (200mg) freeze-drying process:

[0035] Pre-freezing strategy with slow cooling

[0036] (1) Preparation stage: put the tedizolid phosphate sample filled and half-stoppered into the freeze dryer;

[0037] (2) Pre-freezing: set the cooling rate of the freeze dryer to 10°C / h, and keep the temperature for 3 hours when the product temperature drops to -40°C;

[0038] (3) Sublimation drying: turn on the vacuum pump, and when the vacuum degree reaches 20Pa, set the partition to raise the temperature to -20°C at a rate of 5°C / h, and keep it warm for 12h;

[0039] (4) Analytical drying: set the partition to heat up to 40°C at a rate of 20°C / h, keep it warm for 5h after the partition temperature reaches 40°C, and close the aeration valve in the last 2h to keep the freeze-drying box at the ultimate vacuum;

[0040] (5) Plugging: after the freeze-drying finishes, fill the freeze-drying box with nitrogen to 50MPa, and plugging;

[0...

Embodiment 2

[0042] Embodiment 2 tedizolid phosphate for injection (200mg) freeze-drying process:

[0043] Pre-freezing strategy with 2 annealing

[0044] (1) Preparation stage: put the tedizolid phosphate sample filled and half-stoppered into the freeze dryer;

[0045] (2) Pre-freezing: set the cooling rate of the freeze dryer to 10°C / h, keep the product temperature down to -40°C for 1 hour, then raise the temperature to -23°C at a rate of 20°C / h, hold it for 1 hour, and then heat it at 10°C. The cooling rate of ℃ / h is -40℃, keep warm for 2h, after repeated annealing for 2 times, keep warm at -40℃ for 3h;

[0046](3) Sublimation drying: turn on the vacuum pump, and when the vacuum degree reaches 20Pa, set the partition to raise the temperature to -20°C at a rate of 5°C / h, and keep the temperature for 8h;

[0047] (4) Analytical drying: set the partition to heat up to 40°C at a rate of 20°C / h, keep it warm for 5h after the partition temperature reaches 40°C, and close the aeration valve ...

Embodiment 3

[0060] Embodiment 3 Azacitidine for injection (100mg) lyophilization process:

[0061] Pre-freezing strategy with slow cooling

[0062] (1) Preparation stage: put the half-filled azacitidine sample into the freeze dryer;

[0063] (2) Pre-freezing: set the cooling rate of the freeze dryer to 10°C / h, and keep the temperature for 3 hours when the product temperature drops to -45°C;

[0064] (3) Sublimation drying: turn on the vacuum pump, and when the vacuum degree reaches 20Pa, set the separator to raise the temperature to -17°C at a rate of 5°C / h, and keep it warm for 10h;

[0065] (4) Analytical drying: set the partition to heat up to 35°C at a rate of 20°C / h, keep warm for 5 hours after the temperature of the partition reaches 35°C, and close the aeration valve in the last 2 hours to maintain the ultimate vacuum in the freeze-drying box;

[0066] (5) Plugging: after the freeze-drying finishes, fill the freeze-drying box with nitrogen to normal pressure, and plugging;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com