Device and method for growng large diameter 6H-SiC monocrystal with semiconductor property

A growth method and large-diameter technology, applied in the field of crystal growth, can solve the problems that limit the development process of silicon carbide crystals and devices, and achieve the effect of large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

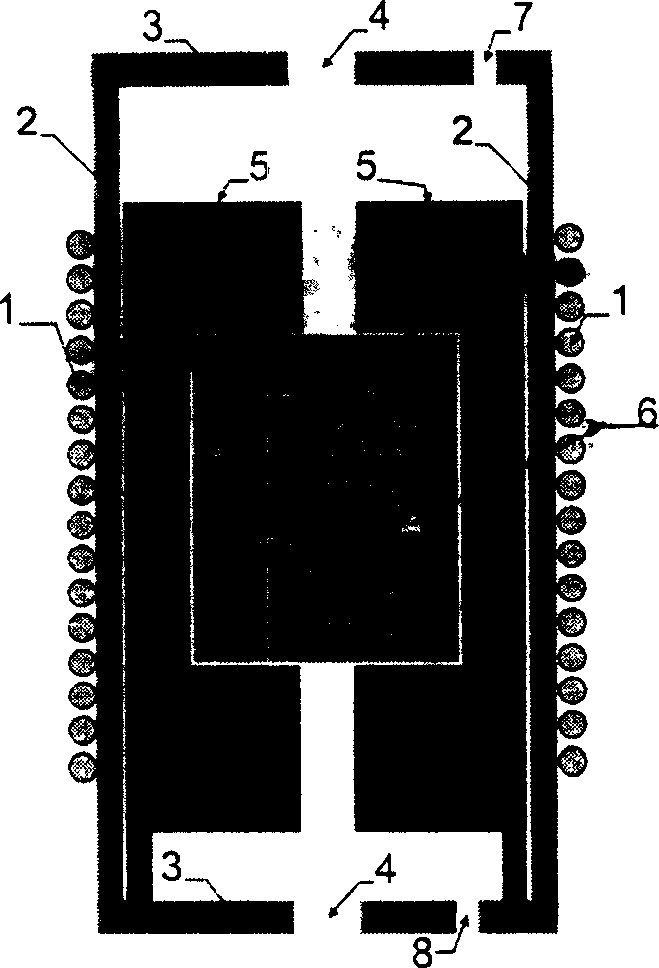

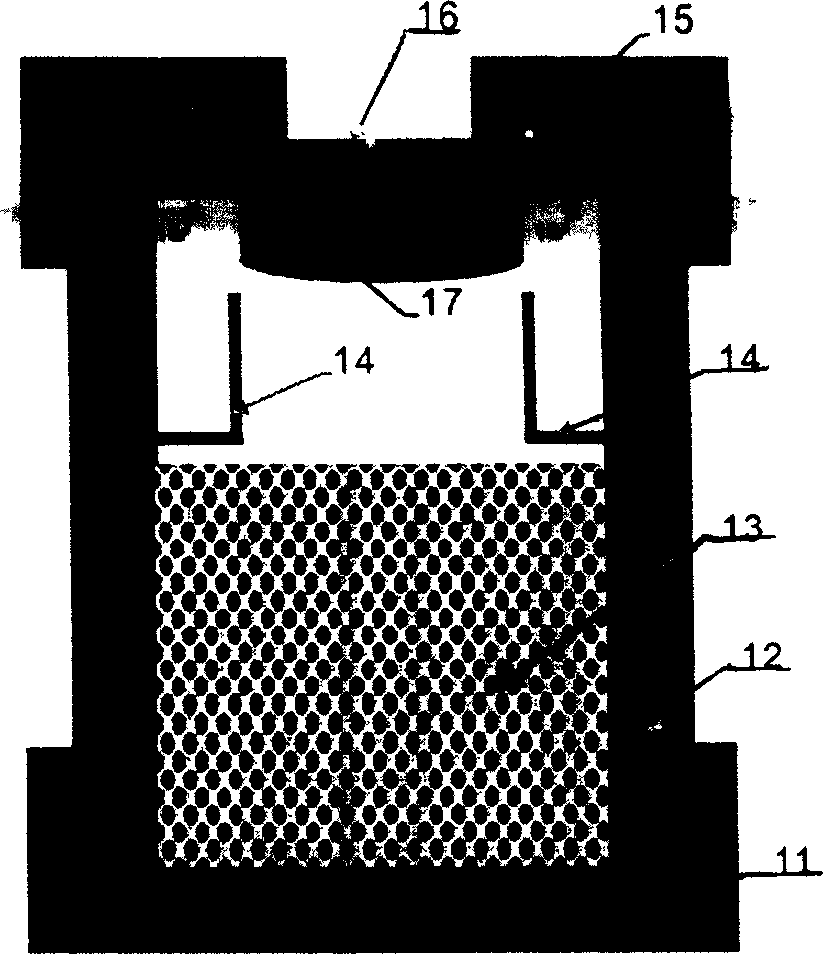

[0036] Embodiment 1. The device of the large-diameter 6H-SiC single crystal of growth semiconductor characteristic, structure such as figure 1 and 2 shown.

[0037] The graphite crucible 6 is placed in the growth chamber. The top of the crucible has a seed crystal seat 16 that can fix the seed crystal, the bottom holds SiC powder 13, and a built-in cylindrical gas phase deflector 14, thereby achieving the purpose of controlling the transport of SiC species . There is a gas port 7 on the upper part of the growth chamber, through which gas enters the growth chamber during the growth process. There is a gas outlet 8 in the lower part of the growth chamber, and vacuum conditions are used to remove harmful substances such as oxygen and water; gas is introduced to provide the atmosphere and pressure required for crystal growth. The upper and lower parts of the growth chamber are hermetically connected by stainless steel flange sealing ring 3 and quartz double-layer glass tube 2, ...

Embodiment 2

[0038] Embodiment 2. A device for growing large-diameter 6H-SiC single crystals with semiconductor characteristics: as described in Embodiment 1, the difference is that there is a built-in cylindrical gas phase deflector 14 and a circular concave crucible wall 12 in the crucible. crystals grown as Figure 4 As shown, the region indicated by the arrow at the end of the crystal grows freely, indicating that the gas phase deflector can effectively control the sublimation and diffusion of the growing species.

Embodiment 3

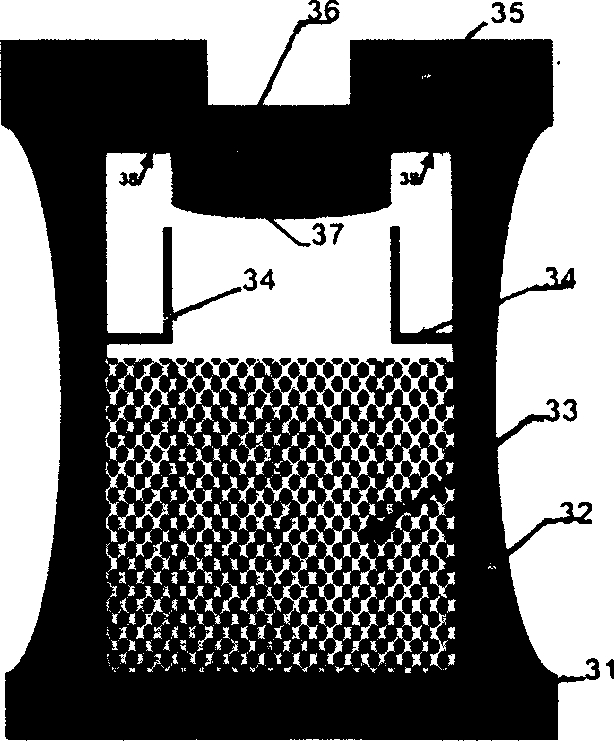

[0039] Embodiment 3. The device for growing a large-diameter 6H-SiC single crystal with semiconductor characteristics: as described in Embodiment 1, the difference is that the side wall of the crucible is an arc-shaped curve 32, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com