Harmless and efficient resource recovery method for waste aluminum electrolysis cell linings and waste cathodes

An aluminum electrolytic cell and resource recovery technology, applied in chemical instruments and methods, inorganic chemistry, carbide, etc., can solve the problems of large impurities in carbon powder, low carbon content, low calcium fluoride content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

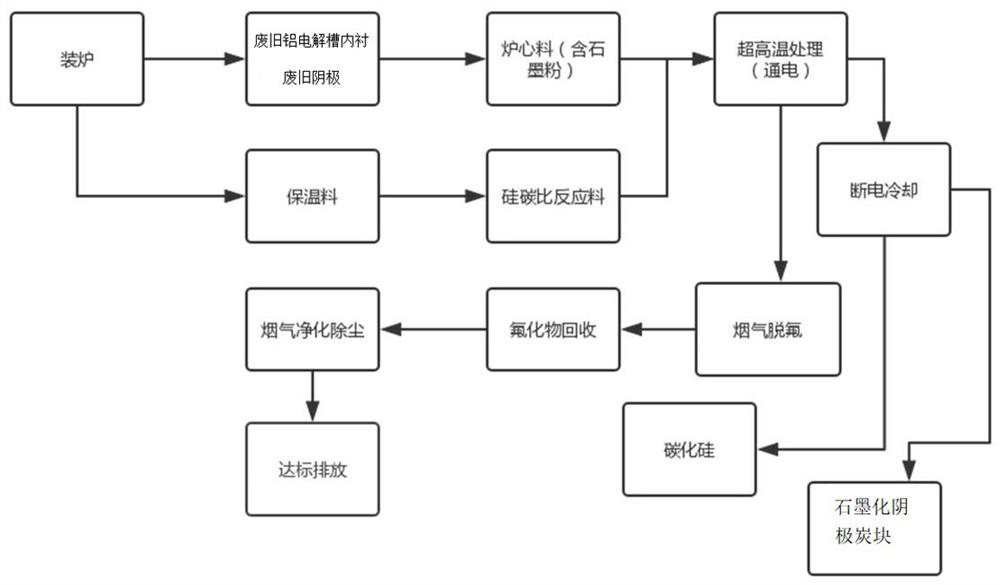

[0022] Harmless treatment and resource recovery of waste electrolyzer linings include the following steps:

[0023] Furnace loading of DC resistance furnace: the bottom layer of the furnace is covered with quartz sand, and the upper layer is covered with carbon-silicon ratio reaction material, which is paved and compacted. The thickness of the quartz sand layer is 600mm, and the mass ratio of silicon to carbon in the carbon-silicon ratio reaction material is 40:60 The separation plates are respectively arranged on both sides of the furnace head to form a furnace core, and the furnace wall is fixed externally; a 150mm thick coke grain bedding layer is laid on the bottom of the furnace core; waste cathode block layers are laid layer by layer in the center of the furnace core from bottom to top, The periphery of the furnace core is surrounded by the waste cathode block layer by layer from bottom to top, and each layer of waste cathode block layer and waste electrolyzer liner layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com