Method for recovering antioxidant 300 from efficient solvent oil mother liquor

A recovery method and solvent oil technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of slow crystallization of antioxidant 300, accidents, and difficult centrifugation, etc. Reduced risk and short centrifugation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

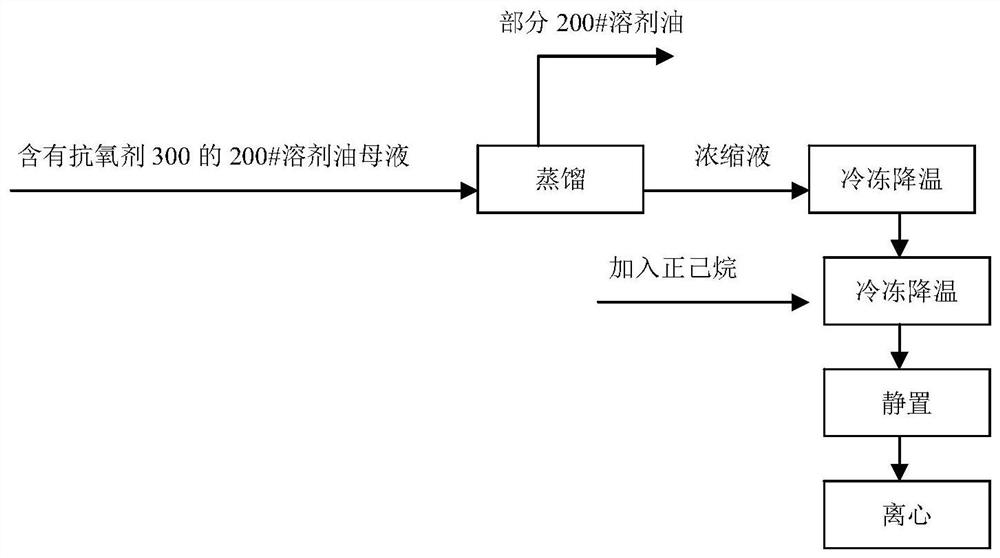

Image

Examples

Embodiment 1

[0026] Distill and concentrate the 200# solvent oil mother liquor containing antioxidant 300 under reduced pressure (-0.08±0.01MPa) at a temperature of 135±5°C, and distill out 200# solvent oil with 30% of the total volume of the mother liquor; put the concentrated solution into recovery Kettle, start stirring (35±5Hz), recover the jacket of the kettle and slowly feed chilled water, stir until the temperature of the concentrated solution is 65±5°C; add n-hexane with 10% volume of the concentrated solution, continue stirring (25±5Hz) to cool down to Stir at -10°C (25±5Hz) for 2 hours; stop stirring, let stand for 12 hours to continue crystallization; then start stirring (50Hz), open the discharge valve of the recovery kettle, put it into a centrifuge for centrifugation (20 minutes), and discharge.

[0027] The obtained antioxidant 300 is white crystal, loose, and its measured melting point is 160.3°C (contains few other by-products). After one purification and weighing, the reco...

Embodiment 2

[0029] Distill and concentrate the 200# solvent oil mother liquor containing antioxidant 300 under reduced pressure (-0.07±0.01MPa) at a temperature of 135±5°C, and distill out 200# solvent oil containing 50% of the total volume of the mother liquor; put the concentrate into recycling Kettle, start stirring (30-40Hz), recover the jacket of the kettle and slowly feed frozen water, stir until the temperature of the concentrated solution is 60±5°C; add n-hexane with 10% volume of the concentrated solution, continue stirring (25±5Hz) to cool down to Stir at -10°C (25±5Hz) for 3h; stop stirring, let stand for 12h to continue crystallization; then start stirring (50Hz), open the discharge valve of the recovery kettle, put it into a centrifuge for centrifugation (20 minutes), and discharge.

[0030] The obtained antioxidant 300 is white crystal, loose, and its measured melting point is 159.9° C. (contains few other by-products). After 2 times of purification and weighing, the recovery...

Embodiment 3

[0032] Distill and concentrate the 200# solvent oil mother liquor containing antioxidant 300 under reduced pressure (-0.07±0.01MPa) at a temperature of 135±5°C, and distill out 200# solvent oil containing 60% of the total volume of the mother liquor; put the concentrated solution into recovery Kettle, start stirring (30-40Hz), recover the jacket of the kettle and slowly feed frozen water, stir until the temperature of the concentrated solution is 70±5°C; add n-hexane with 10% volume of the concentrated solution, continue stirring (25±5Hz) to cool down to Stir at -10°C (25±5Hz) for 2 hours; stop stirring, let stand for 12 hours to continue crystallization; then start stirring (50Hz), open the discharge valve of the recovery kettle, put it into a centrifuge for centrifugation (20 minutes), and discharge.

[0033] The obtained antioxidant 300 is white crystal, loose, and its measured melting point is 159.7°C (contains few other by-products). After one purification and weighing, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com