Longitudinal shifting carrier for cars

A truck, vertical technology, applied in the field of parking and handling equipment in garages, can solve the problems of life, poor reliability, many hydraulic cylinder pipelines, inconvenient operation, etc., and achieve the effects of flexible and durable operation, relatively low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

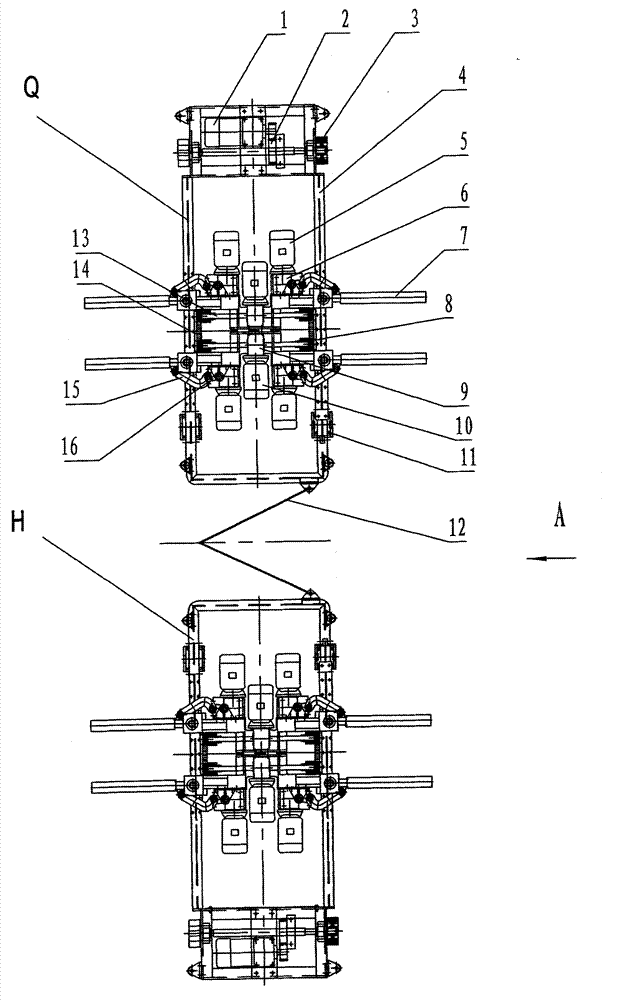

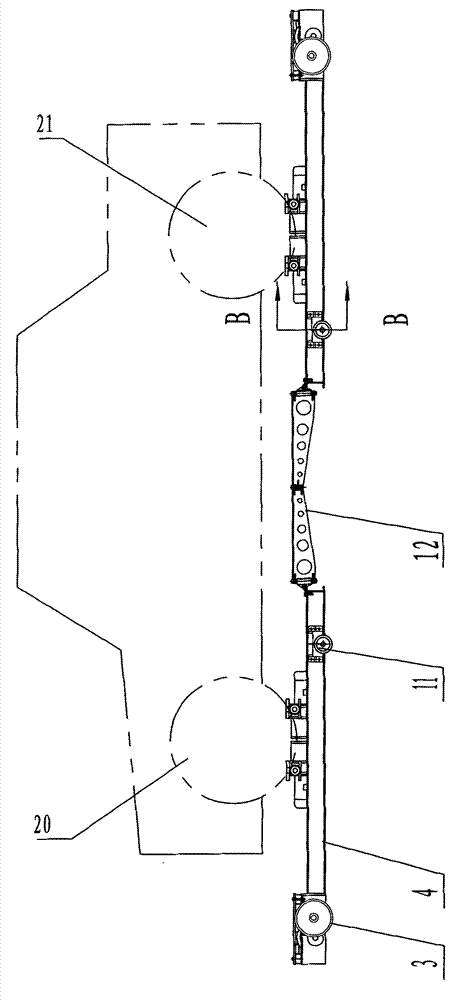

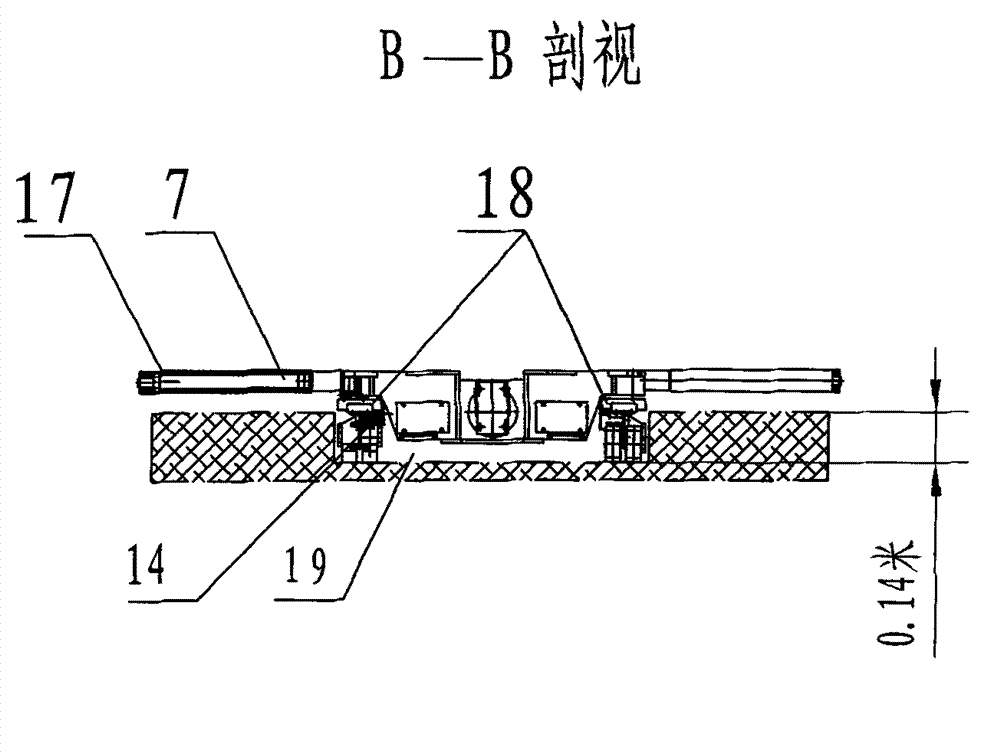

[0028] see Figure 1 to Figure 7 , the car longitudinally translates the transport vehicle, including the front trolley Q and the rear trolley H. The two trolleys are connected by a movable link chain 12. The running mechanism of each trolley includes two driving wheels 3 and two slave wheels. Moving wheel 11 (each wheel can be a single wheel or two wheels) and motor 1 and its reducer 2; each walking trolley does not have two pairs of wheel clamping arm mechanisms on the left and right to clamp the car tires of the car placed on the ground (2 front wheels 20, 2 rear wheels 21), and be provided with wheel synchronous clamping lifting mechanism. Two pairs of wheel clamping arm mechanisms on the left and right are provided on each walking trolley, and the structure of each wheel clamping arm mechanism is: the motor 5 is connected to the input shaft of the worm gear reducer 6, and the worm gear reducer 6 The output shaft of the output shaft links to each other with rocking arm (o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com