Adjustable-axle distance roller device

A technology of adjusting device and roller, which is applied in the direction of measuring device, testing/calibration of speed/acceleration/shock measuring equipment, force/torque/power measuring instrument, etc., which can solve the difficulty of driving out of the wheel, the limitation of vehicle range, and the reduction of detection accuracy To achieve the effect of expanding the range of vehicles, improving detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes and in conjunction with the accompanying drawings.

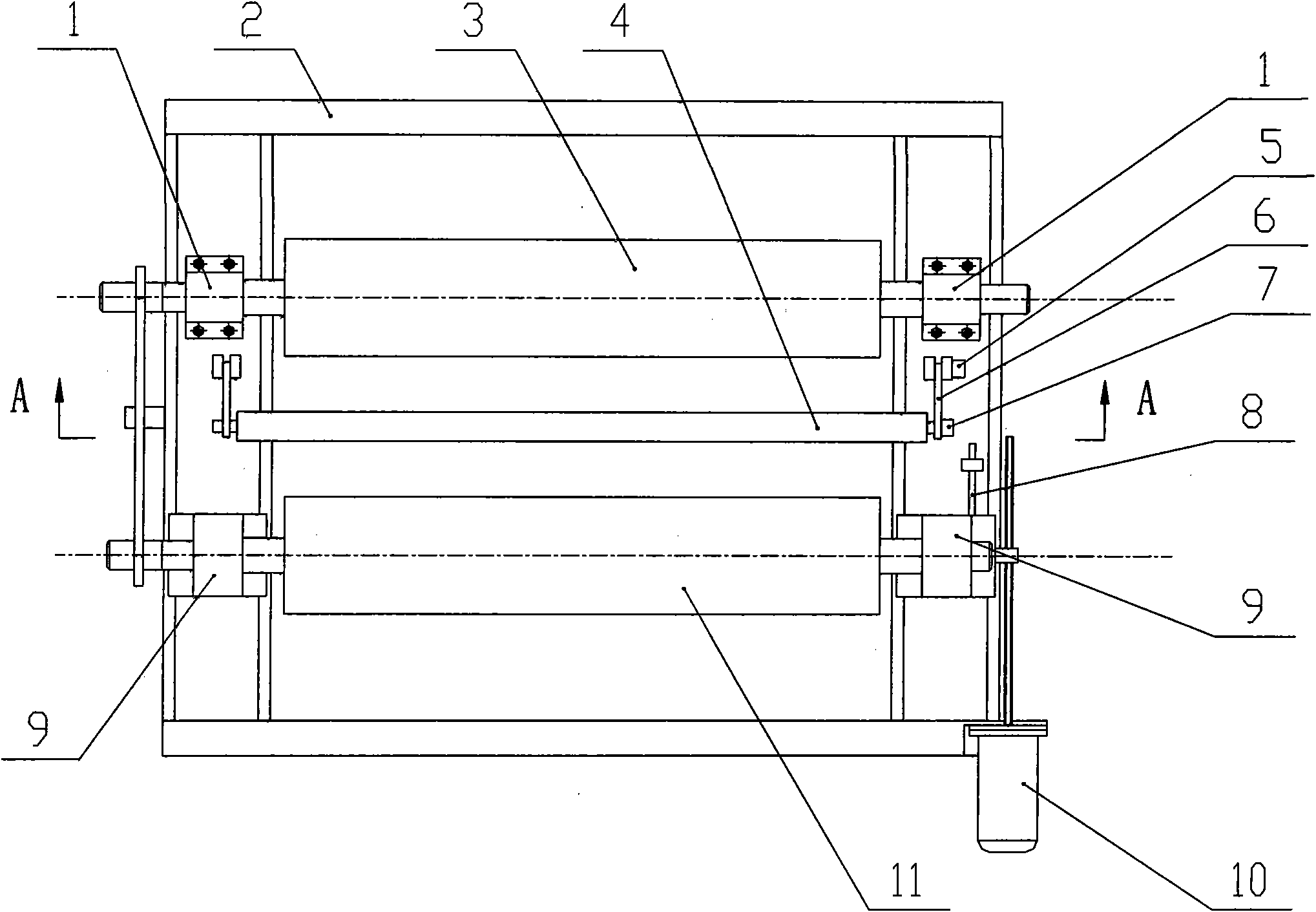

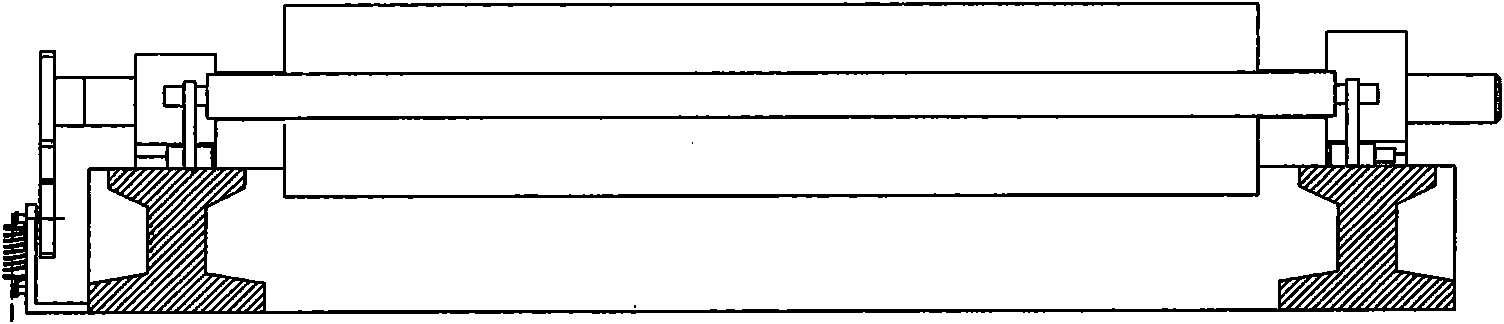

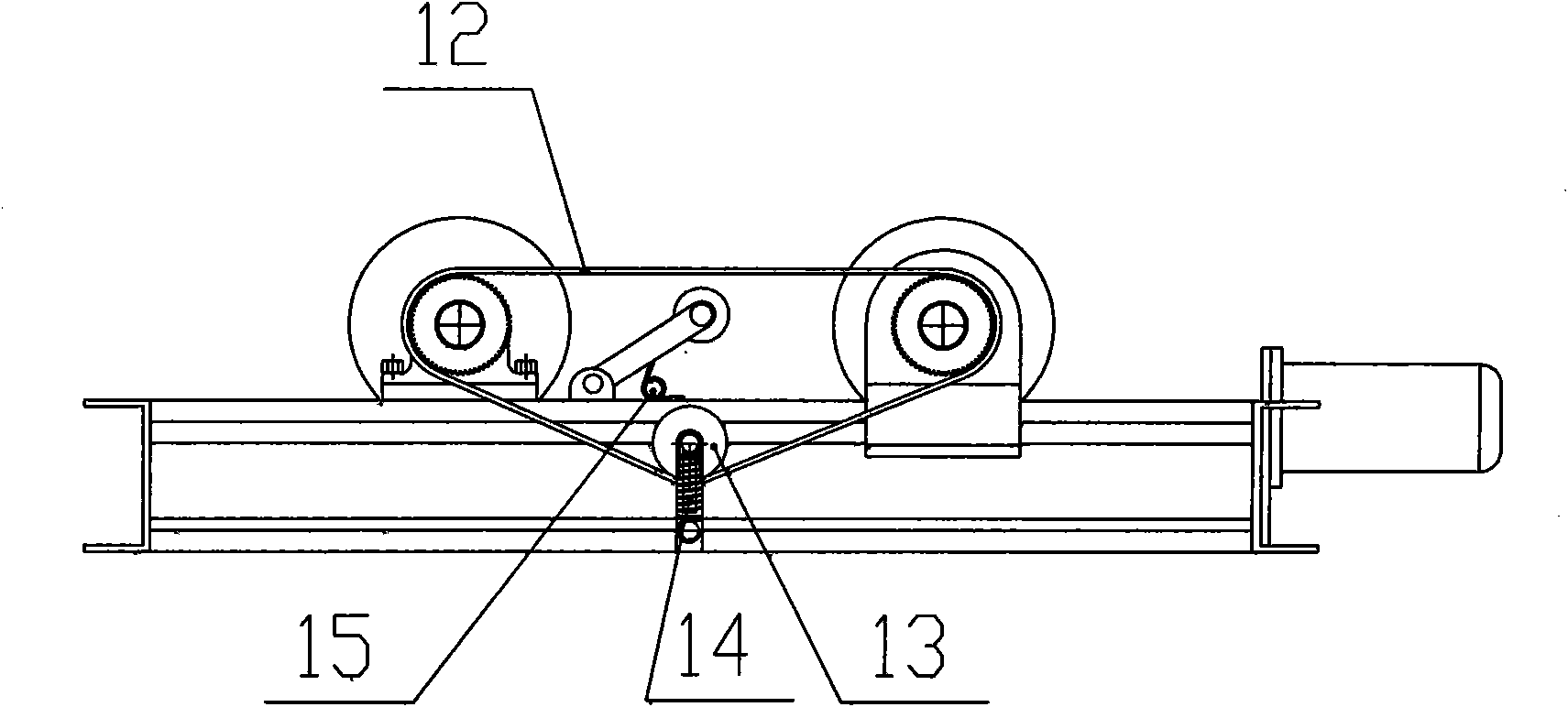

[0013] Such as figure 1 , figure 2 , image 3 The roller device with adjustable wheelbase includes frame 2, main roller 3, auxiliary roller 11, tire diameter detection device, roller wheelbase detection and adjustment device, transmission device 12 and tensioning mechanism, main roller 3 and The auxiliary rollers 11 are linked by the transmission device 12. The main roller 3 is fixedly supported on the frame 2 through the bearing seat 1. There are two I-shaped guide rails on the frame 2. The auxiliary roller 11 is supported on the guide rails through the bearing seat 9. Above; the tire diameter detection device includes a sensing roller 4, a bracket 6, a spring 15, and a position sensor 5. One end of the bracket 6 is hinged on the frame 2, and the other end supports the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com