Container storage warehouse

A container-type, car storage warehouse technology, which is applied to buildings, building types, buildings, etc. where cars are parked, can solve the problems of insufficient loading capacity, many restrictions on use, and low loading and unloading efficiency, so as to improve loading and unloading efficiency and prolong use The effect of improving the service life and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

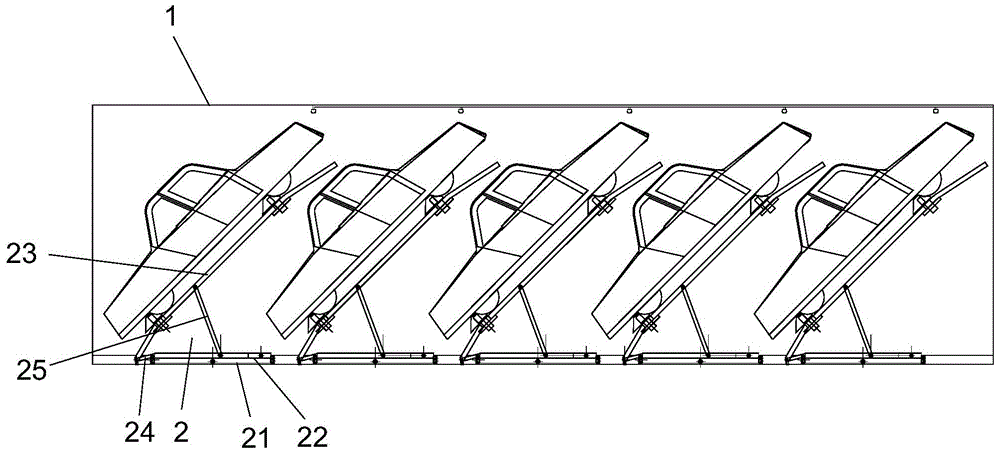

[0026] The container type car storage storehouse of the present invention, as Figures 1 to 8 As shown, a container box body 1 is included, and a plurality of three-dimensional vehicle frames 2 are installed in the container box body 1, and the three-dimensional vehicle frames 2 are arranged in a row in the container box body 1.

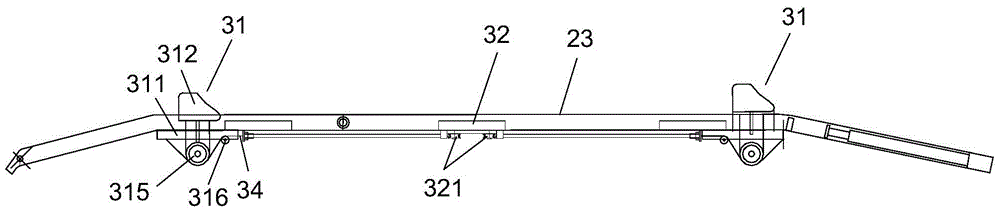

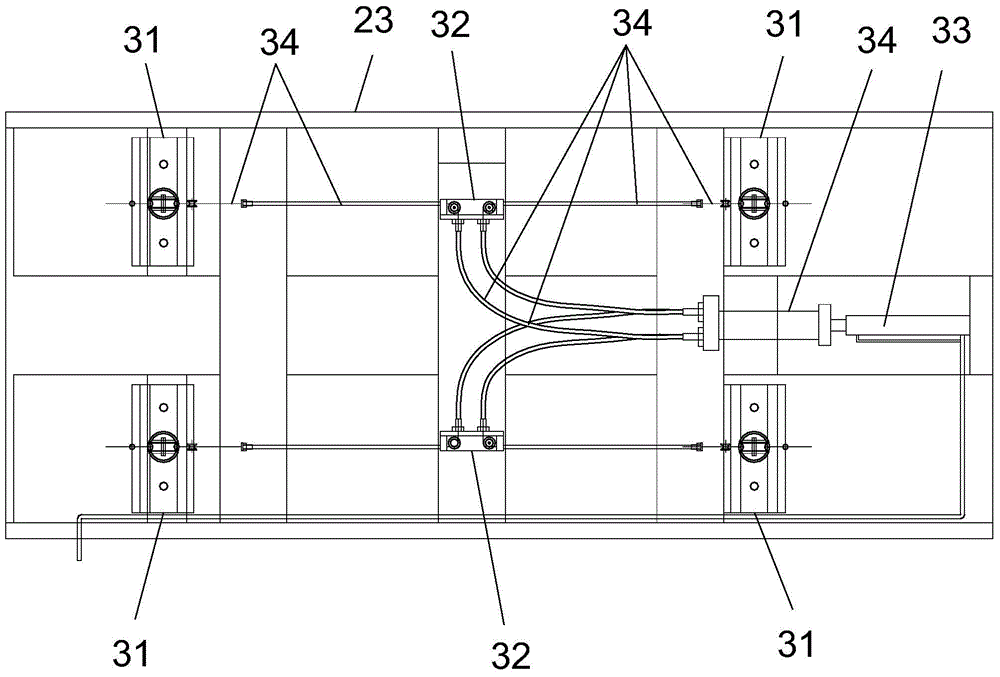

[0027] The three-dimensional vehicle frame 2 comprises a base 21, a mobile frame 22 and a parking plate 23. A traverse slide rail is installed in the container box body 1. The traverse slide rail is arranged along the length direction of the container box body 1. The base 21 is slidably installed on the traverse slide rail. On the rail, the base 21 is provided with a longitudinal sliding rail, and the mobile frame 22 is slidably installed on the vertical sliding rail.

[0028] The push-pull slide rail is parallel to the traverse slide rail, and the longitudinal slide rail is perpendicular to the traverse slide rail.

[0029] The rear end of the park...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com