Leveling system and leveling method for agricultural power chassis

An agricultural power and chassis technology, which is applied to agricultural vehicles, motor vehicles, elastic suspensions, etc., can solve the problems of vehicle chassis that are difficult to maintain level, uneven ground, hilly and slope terrain, etc., and achieve the goal of improving operation quality and application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

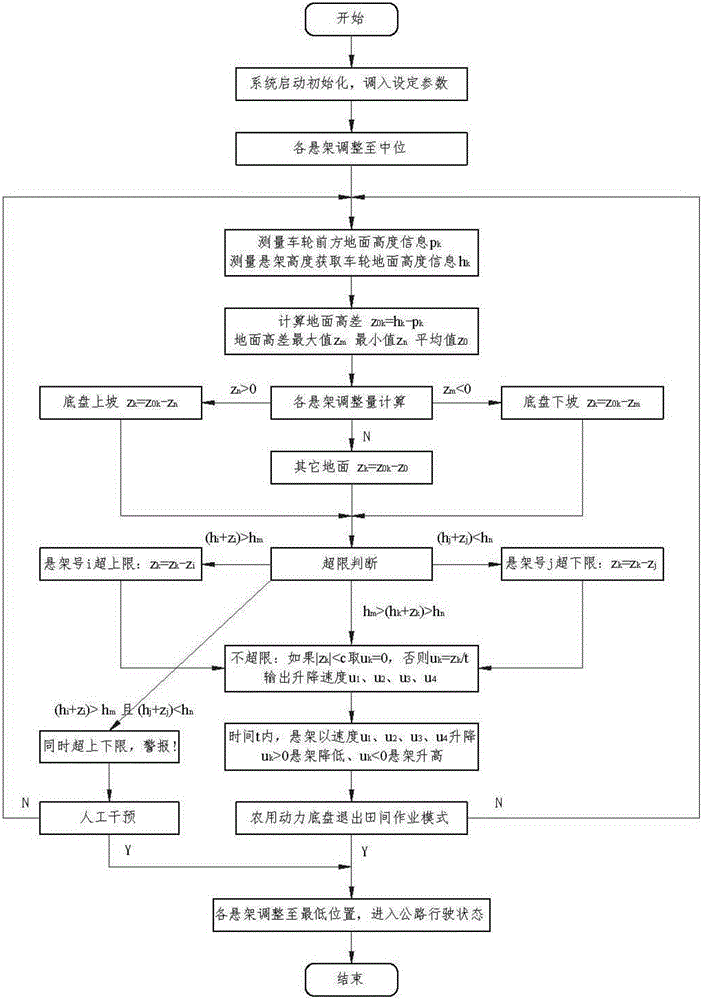

[0031] The specific implementation manners of the present invention will be described in further detail below according to the drawings and examples.

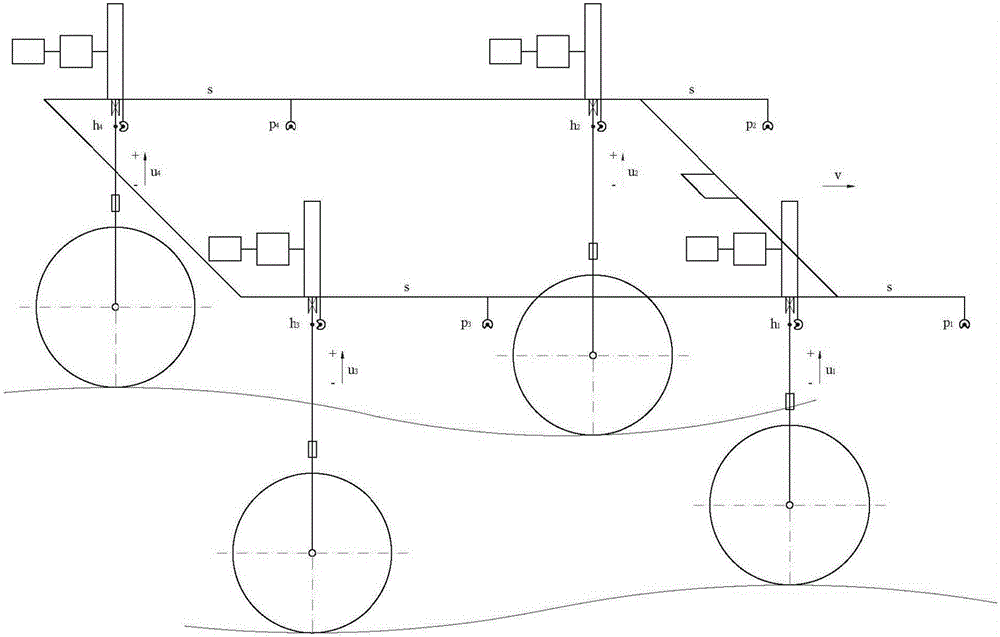

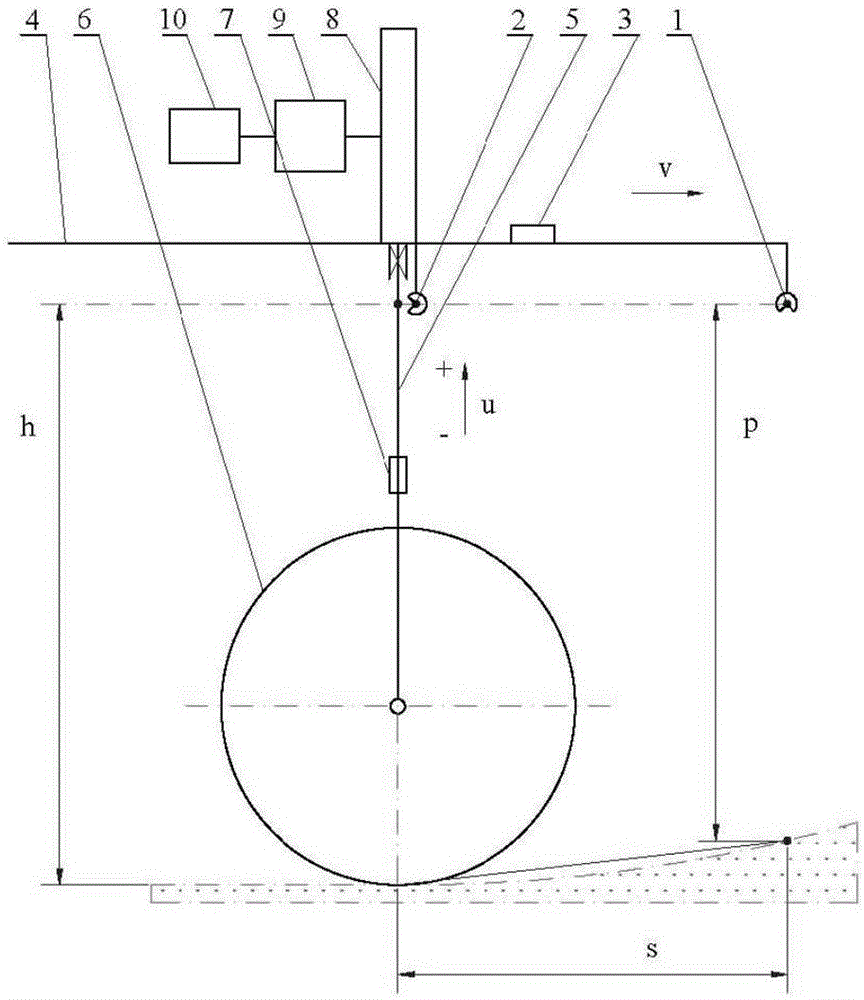

[0032] figure 1 The schematic diagram of the agricultural power chassis leveling system is shown. The agricultural power chassis leveling system includes: distance measuring sensor 1, position sensor 2, central processing unit 3, frame 4, suspension 5, wheels 6, four sets of suspension 5 According to the given wheelbase and wheelbase, it is symmetrically installed on the upper part of the vehicle frame 4, and the lower part is connected with the wheels 6 to form a four-wheel agricultural power chassis. Four sets of ranging sensors 1 are installed on the vehicle frame 4 and located directly in front of each wheel. At a distance s, four sets of position sensors 2 are installed on the suspension 5 respectively, and the frame 4 is provided with a central processing unit 3 to form a four-wheel agricultural power chassis leveling sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com