Corn harvesting header applicable to areas of mountains, hills and plains

A technology for harvesting headers and headers, applied in the agricultural field, can solve problems such as low operating efficiency, inability to meet corn harvesting operations in plain areas, poor stability of climbing ability, etc., and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

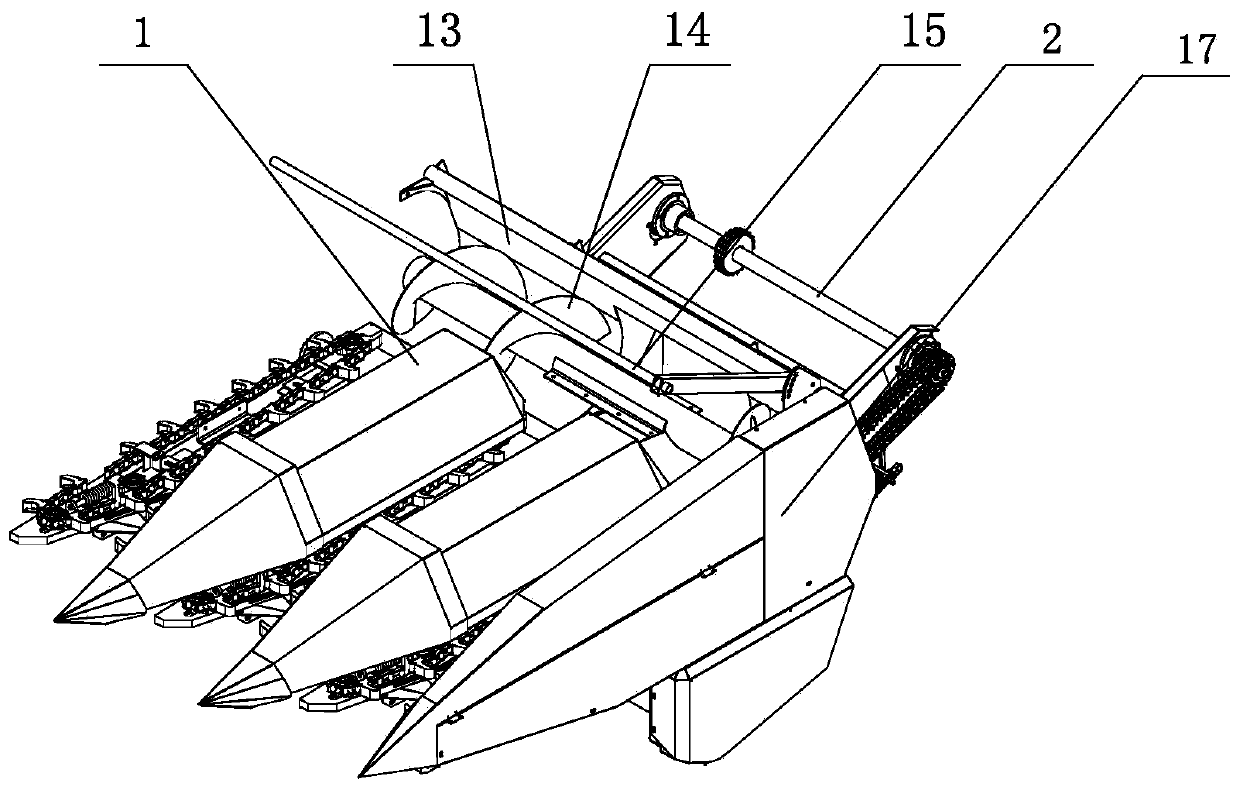

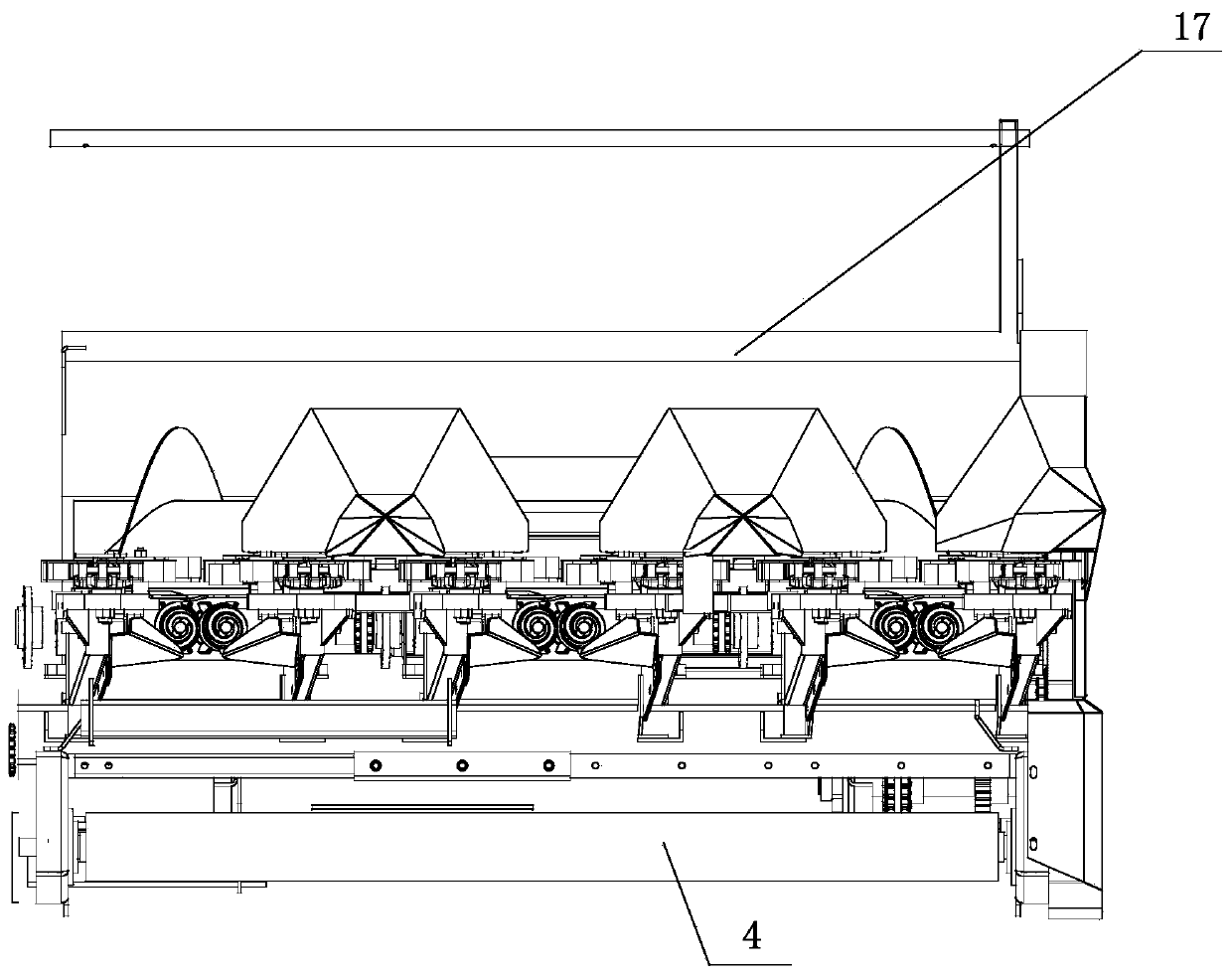

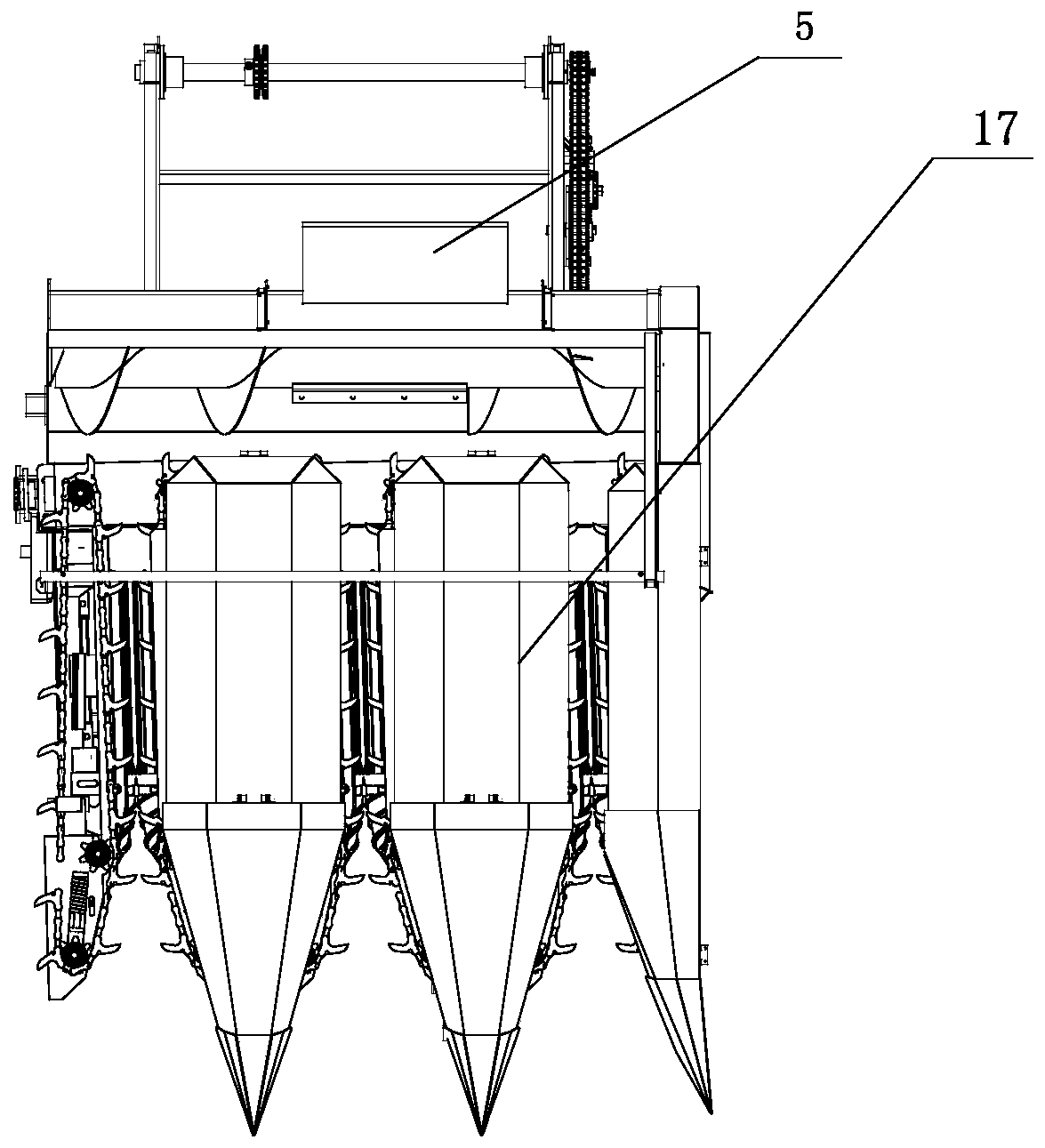

[0032] Such as Figure 1-9 The corn harvesting header suitable for mountainous, hilly and plain areas as shown includes a single header body 16, a long header body 17, a header coupling frame 2 and a header shield 1, and the single header body 16 is provided with the short header auger casing 8, the header short auger 7, the short straw stalk 6, a group of fringe picking components and the short front straw chopping and returning machine 3 from the back to the front. The table body 17 is sequentially provided with a long header auger housing 13, a long header auger 14, a long straw stalk 15, three groups of ear picking components and a long front straw chopping and returning machine 4 from the back to the front. The header coupling frame 2 is fixedly connected to the rear portion of the long header body 17, the rear portion of the long header body 17 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com