Pneumatic tire and tire mold

A technology for pneumatic tires and forming molds, applied to tire treads/tread patterns, tire parts, tires, etc., can solve problems such as stone trapping, crack damage at the bottom of grooves, and entry, etc., and achieve excellent WET performance, excellent The effect of anti-stone trapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

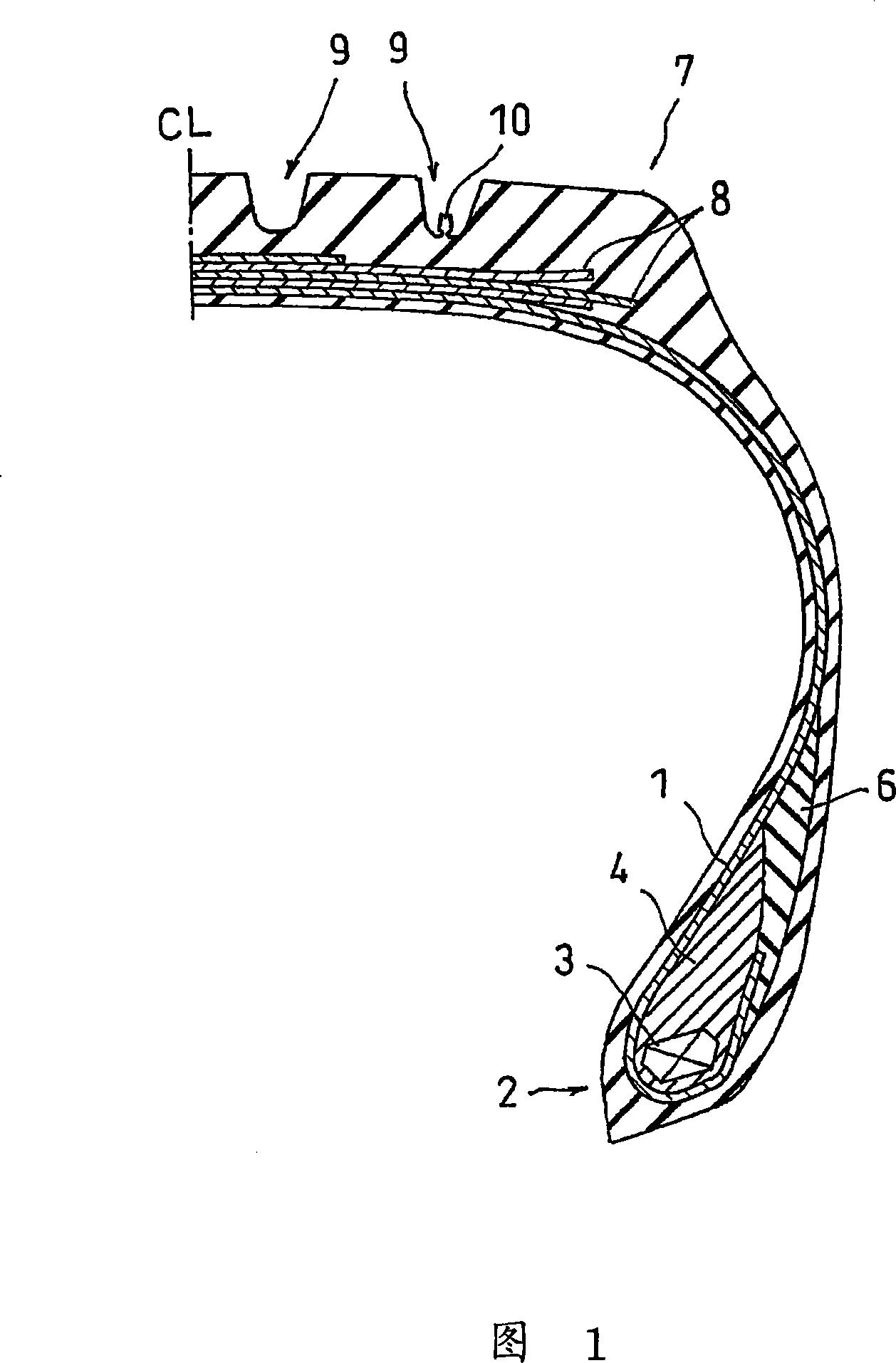

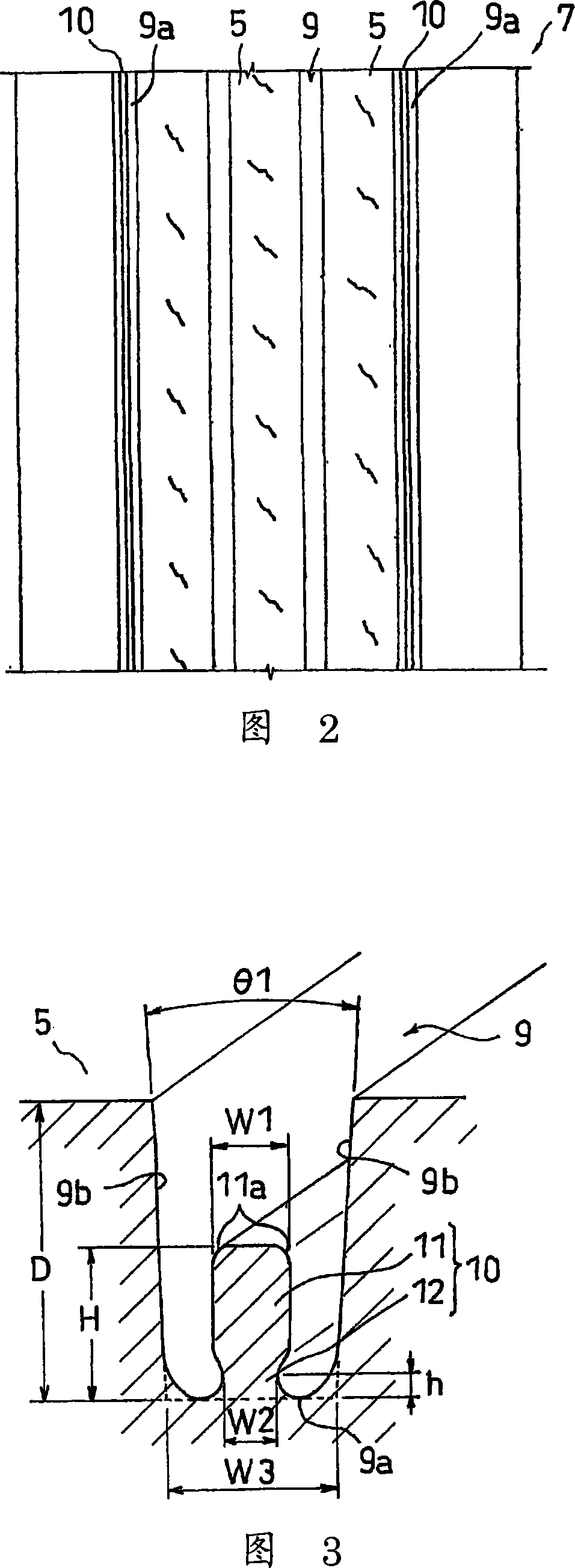

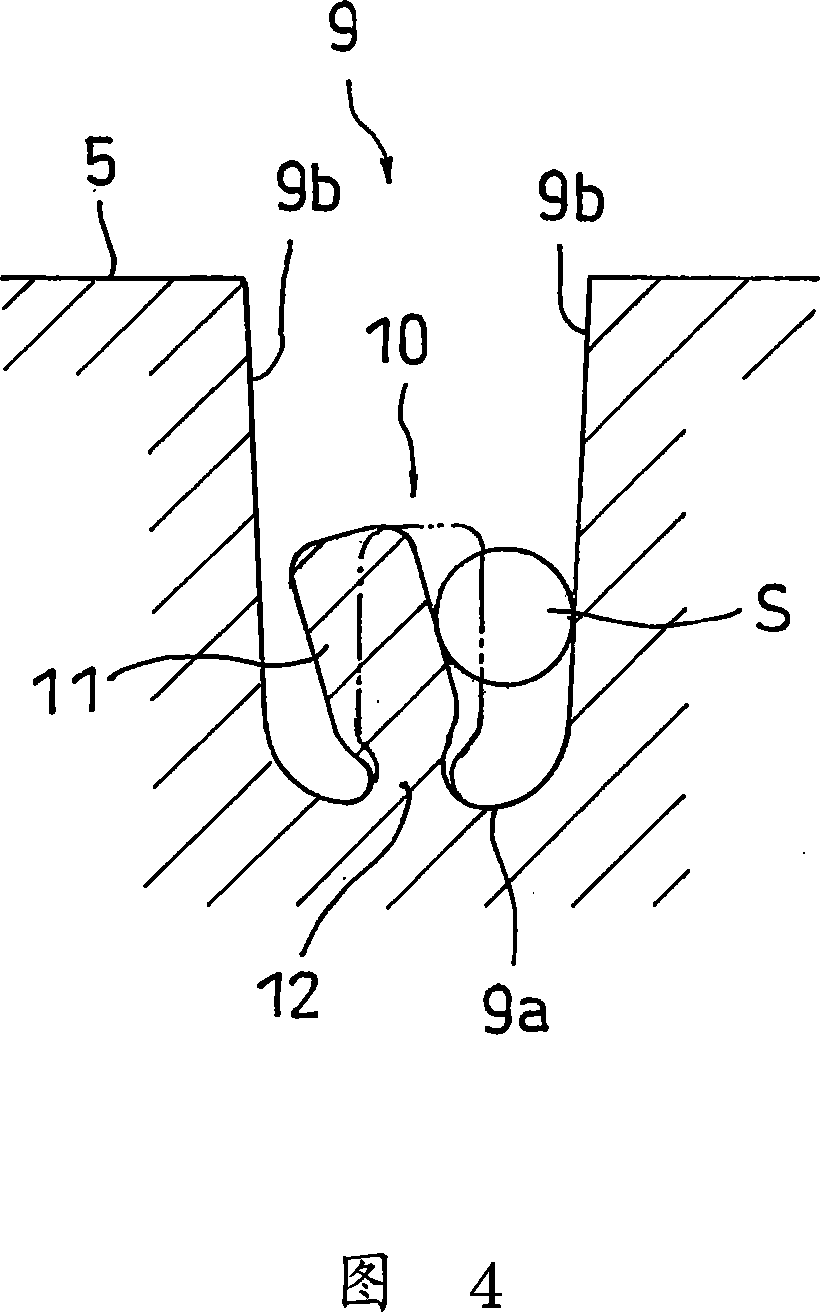

[0051] Fig. 1 is a tire meridian half sectional view showing an example of a pneumatic tire of the present invention. Fig. 2 is a developed view of the tread of the pneumatic tire. Fig. 3 is a sectional oblique view when a part of Fig. 1 is enlarged and viewed obliquely.

[0052] As shown in Figures 1 and 2, in this embodiment, on the outer peripheral side surface of the tread portion 7, that is, on the tread, a circumferential groove 9 as a groove portion is continuously provided along the tire circumferential direction, and the circumferential groove 9 divides The resulting land portion has a rib pattern with the rib 5 as the main tone. On the groove bottom 9 a of the outermost circumferential groove 9 in the tire width direction among the four circumferential grooves 9 , protrusions 10 are provided extending in the extending direction of the circumferential groove 9 , that is, in the tire circumferential direction.

[0053] As shown enlarged in FIG. 3 , the protrusion 10 ...

no. 2 Embodiment approach

[0073] The structure of the second embodiment is the same as that of the first embodiment except for the following structures of the groove portion and the ridge, so the common points will be omitted and the differences will be mainly described. In addition, the same reference numerals are assigned to the same members as those described in the first embodiment, and overlapping descriptions will be omitted.

[0074] As shown in FIG. 6 , the protrusion 20 includes a crown 21 constituting the upper body and a base 22 constituting the lower body. The crown 21 has a substantially circular cross-section, protrudes toward the outer peripheral side of the tire, and is formed by a curved surface that protrudes toward the groove wall 9b side from the front end to the side. The shape of the base 22 is substantially the same as that of the base 12 of the first embodiment, and integrally connects the crown 21 and the groove bottom 9a.

[0075] In the present embodiment, since the protrusi...

no. 3 Embodiment approach

[0078] The structure of the third embodiment is the same as that of the first embodiment except that the grooves and ridges have the following structures, so the common points will be omitted and the differences will be mainly described. In addition, the same reference numerals are assigned to the same members as those described in the first embodiment, and overlapping descriptions will be omitted.

[0079] As shown in FIG. 7 , the protrusion 30 includes a crown 31 constituting the upper body and a base 32 constituting the lower body. The crown 31 has a substantially rectangular cross-section and protrudes toward the tire outer peripheral side with a protrusion height smaller than that of the crown 11 in the first embodiment. The shape of the base 32 is substantially the same as that of the base 12 of the first embodiment, and integrally connects the crown 31 and the groove bottom 9a.

[0080] In this embodiment, the groove wall angle θ2 of the circumferential groove 9 is set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com