Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc. It can solve the problems of deterioration of operational stability and difficulty in satisfying improvements, and achieve improved hand feeling and improved braking Performance and cornering performance, the effect of improving quietness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

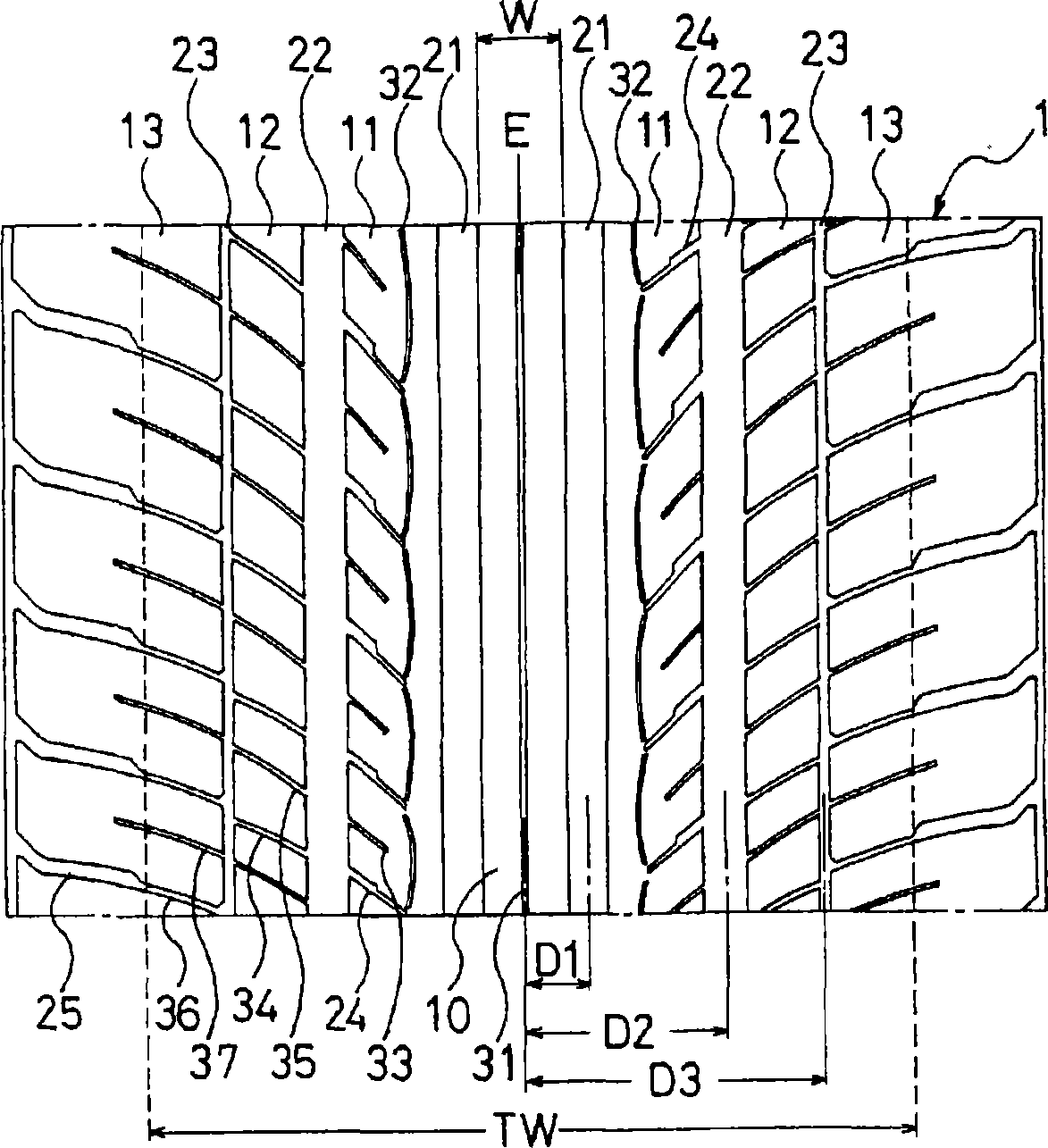

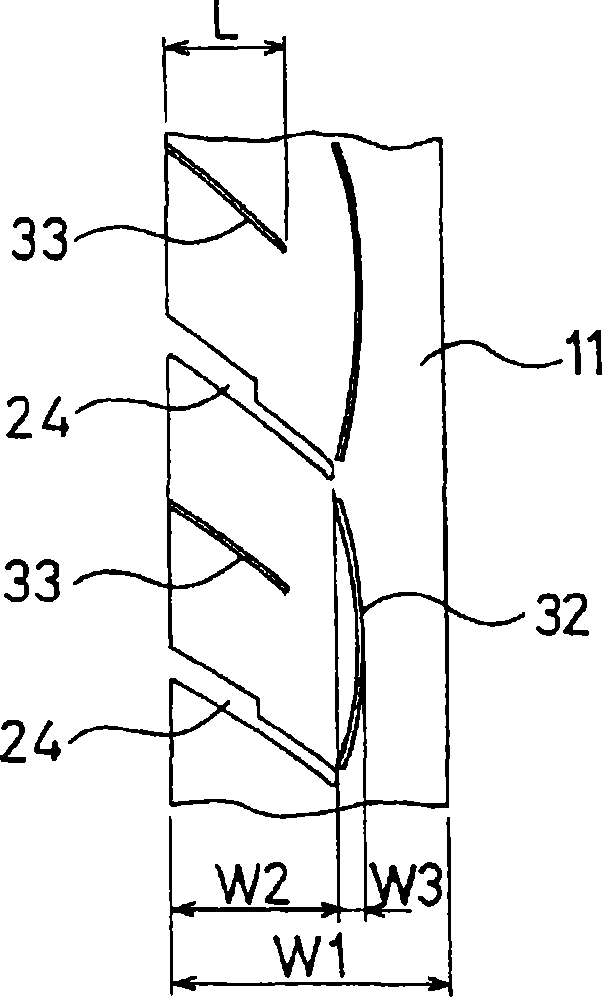

[0033] Among pneumatic tires with a tire size of 205 / 65R15, the tires of Examples 1 to 3 were produced respectively, and these tires formed figure 1 Such a tread pattern, and the ratio of the minimum distance W2 between the wavy or zigzag thin grooves formed on the first land portion and the outer wall surface of the first land portion to the width W1 of the first land portion (W2 / W1×100), and the ratio (W3 / W1×100) of the amplitude W3 of the wavy or zigzag narrow grooves formed on the first land portion to the width W1 of the first land portion (W3 / W1×100) are shown in Table 1, respectively. different.

[0034] For comparison, tires of Comparative Examples 1 to 3 in which the respective ratios were varied as shown in Table 1 were produced. In addition, in Comparative Examples 1 and 2, no fine grooves were provided in the rib-shaped land portion located in the tread center portion.

[0035] For these test tires, wet cornering performance, wet braking performance, noise perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com