High-performance copper-based shape memory alloy material

A memory alloy and high-performance technology, applied in the field of high-performance copper-based shape memory alloy materials, can solve the problems of difficult processing, low fatigue life, and poor memory alloy fatigue, and achieve a major market competitive advantage and cost-effective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

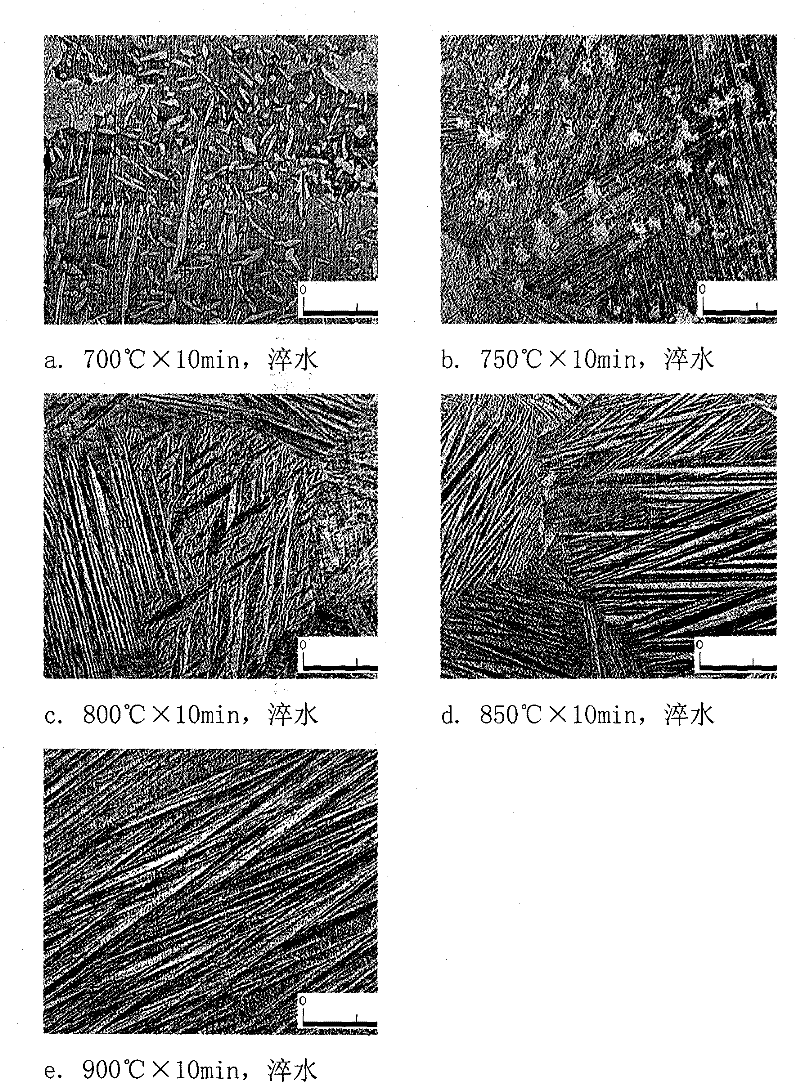

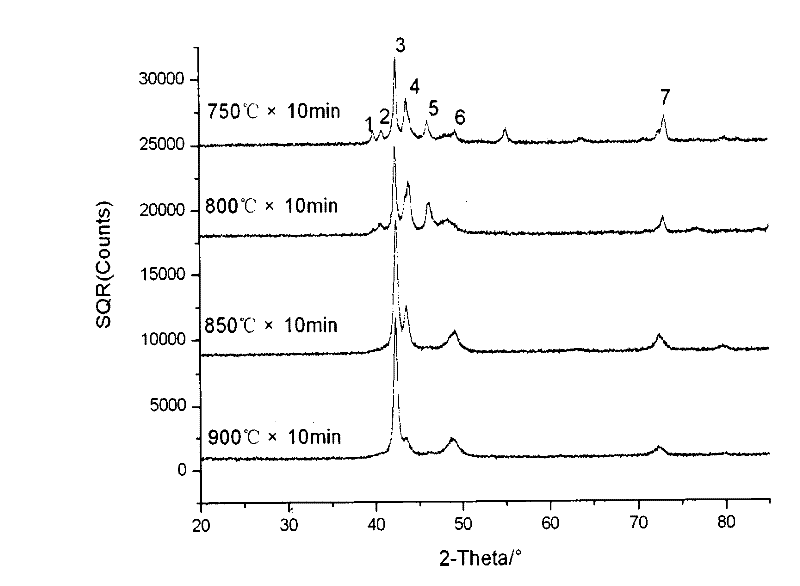

Image

Examples

Embodiment 1

[0029] A high-performance copper-based shape memory alloy material formula, which is composed of copper, zinc, aluminum, and trace elements rhenium and zirconium and a mixed solvent, wherein the weight percentage of each component is,

[0030]

[0031] Mixed solvent 0.6%, wherein mixed solvent is made up of potassium chloride, cryolite and sodium chloride, and its ratio is 1:3:9.

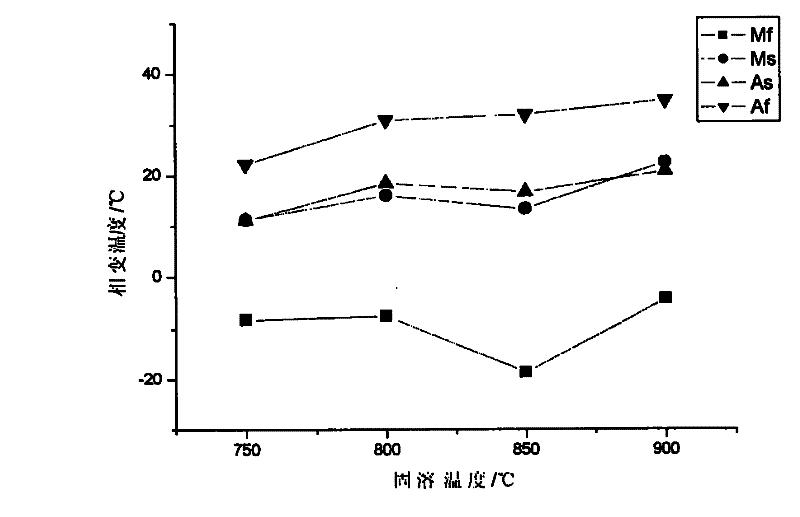

[0032] In Cu-Zn-Al alloy, the content change of Zn and Al has a great influence on the phase transition temperature of the alloy. For every 0.1% increase in Al content, the phase transition point will drop by about 15-20°C, and for every 0.1% increase in Zn content , the phase transition point drops by about 6-7°C; it is worth mentioning that the amount of Al element in the Cu-Zn-Al alloy is generally controlled between 3.5-6.5%. When the Al element content is higher than 6.5%, the alloy will be embrittled, making the forming process more difficult; and when the Al element content is lower than 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com