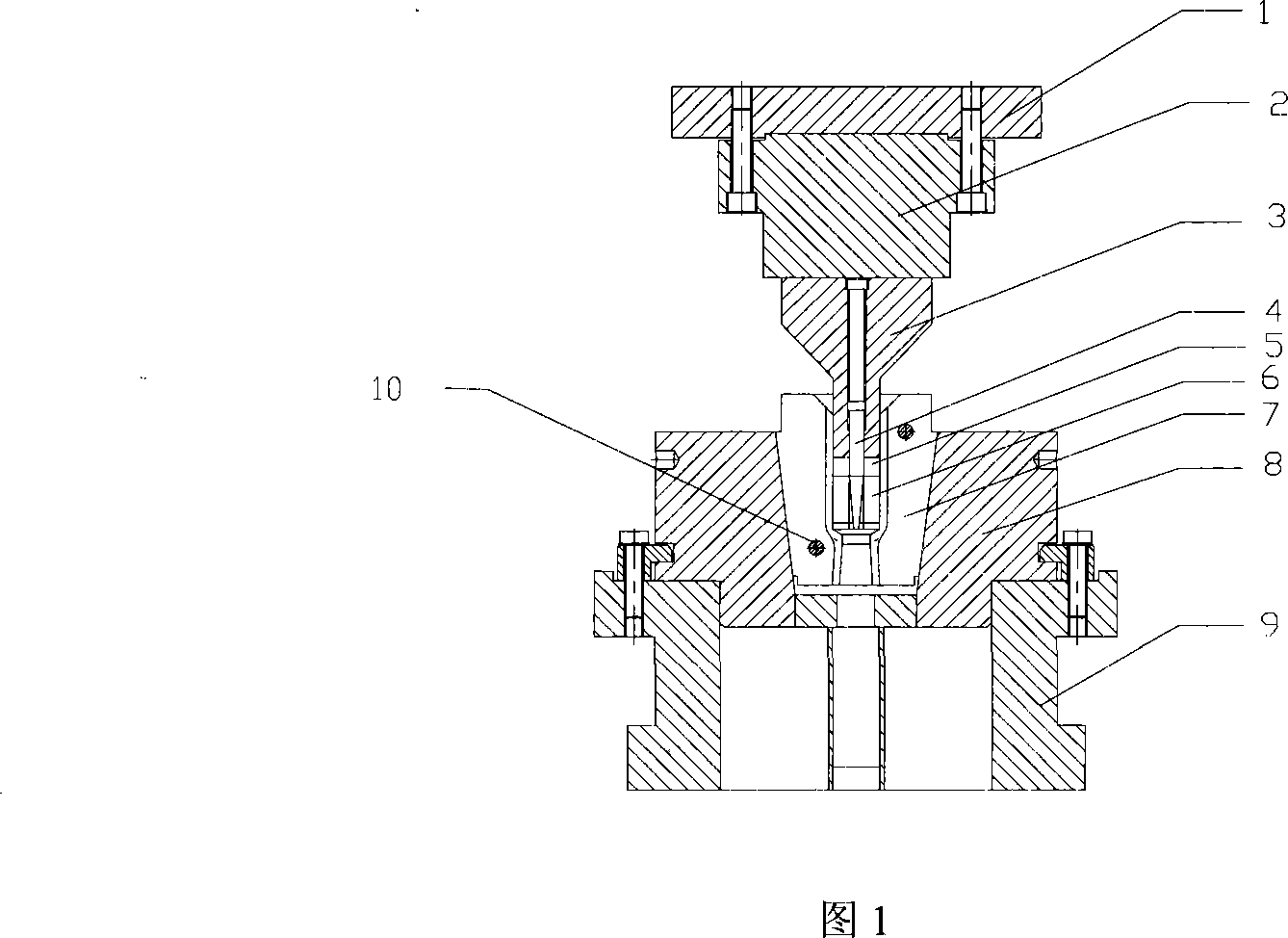

High rate NiTi alloy pipe blank hot extruding mold

A hot extrusion die, high-speed technology, applied in the direction of metal extrusion dies, etc., can solve the problems of reducing overall cost, difficult forming, high scrap rate, etc., to reduce the temperature of the billet, improve the utilization rate of materials, and improve the quality of microstructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

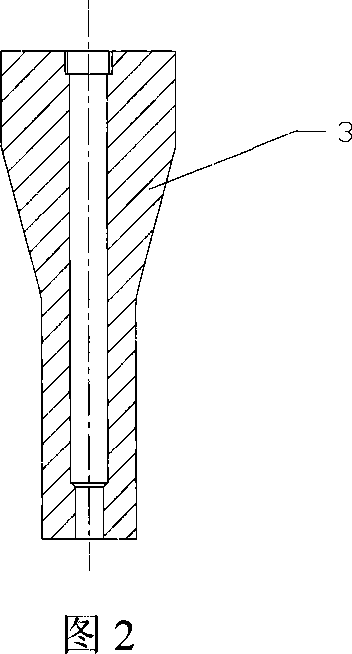

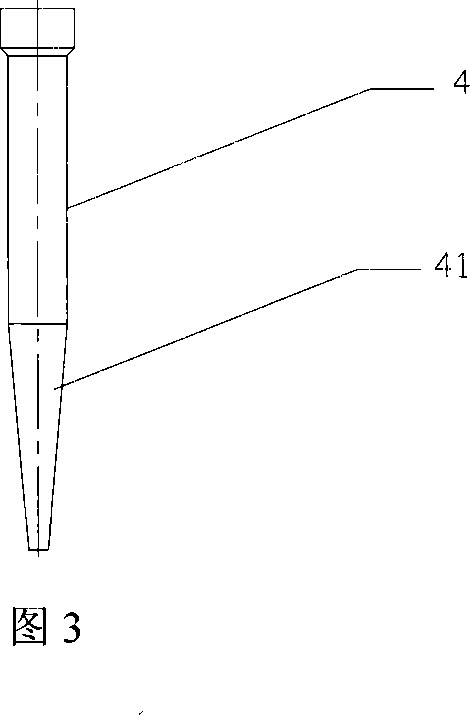

Method used

Image

Examples

Embodiment

[0045] The NiTi alloy is taken, smelted by the above process, forged into a Φ55mm round bar, and machined into a Φ49mm×55mm extrusion billet with an inner diameter of 16mm. Preheat the extruded billet to 120°C, spray the glass lubricant on the spray gun (Ti-5D glass lubricant is used in this embodiment), and then put it into a high-temperature furnace, and continue to Heat to 960-1130°C and keep warm for 20 minutes. The mold is preheated to 120°C and sprayed with graphite powder for lubrication, and then the heating is continued. The extrusion shaft and extrusion needle are heated to 300°C, and the extrusion die is heated to 500°C, all of which are heated as a whole. The extrusion speed is 400-500mm / s, and the time from taking out the extrusion billet to the start of extrusion shall not exceed 10 seconds. After extrusion, the pipe billet is stress-relieved and annealed. The process is to install a furnace at 700 ° C, heat it to 830 ° C, keep it for 30 minutes to 1 hour, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com