Method for forming complex NiTi alloy component through additive manufacturing

A technology of additive manufacturing and complex structures, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency, etc., to achieve the effects of short manufacturing cycle, good interlayer bonding, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

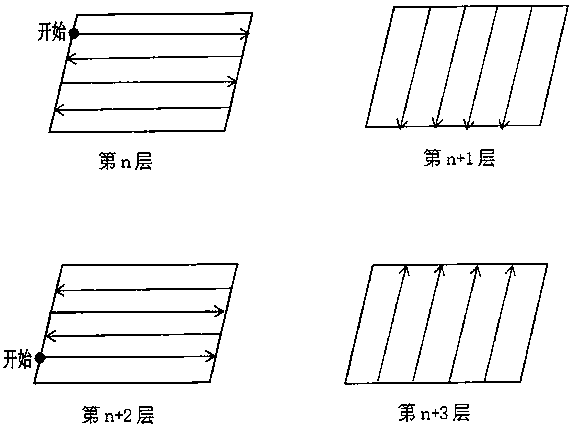

Image

Examples

Embodiment

[0020] Embodiment: the embodiment of the present invention comprises the following steps:

[0021] The Ni, Ti, and Nb element powders are based on the ratio of the atomic ratio Ni:Ti:Nb=50.6:47.4:2, and the NiTi alloy powder is prepared by a gas atomization method. Nickel with a purity of 99.99%, titanium with a purity of 99.9%, and niobium with a purity of 99.8% are degreased, cleaned, and dried, and put into a crucible according to the proportion, and heated and smelted in an electric furnace under the protection of argon. When the metal is impacted by the high-speed and high-pressure argon gas in the atomization tower to the liquid flow through the nozzle, it will be hit into mist droplets, and the droplets will cool and solidify into NiTi metal powder during the falling process, with a particle size of 0.020-0.040mm. Dry the powder in a drying oven at 160°C for 1 to 1.5 hours, then set aside;

[0022] Install a metal substrate at the bottom of the forming cavity to provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com