Infrared reflection/emission thermal-insulating plastic functional master batch and preparation method thereof

A technology of infrared reflection and functional masterbatch, which is applied in the field of plastics, can solve problems such as time-consuming, laborious and environmental pollution, and achieve the effects of avoiding environmental pollution, improving the environment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

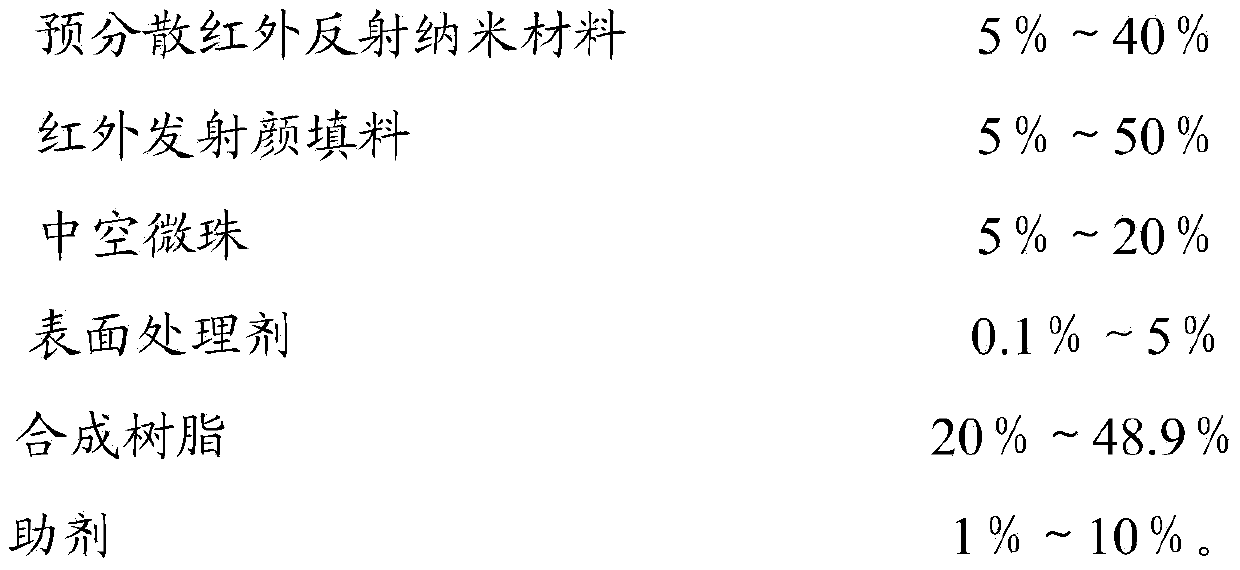

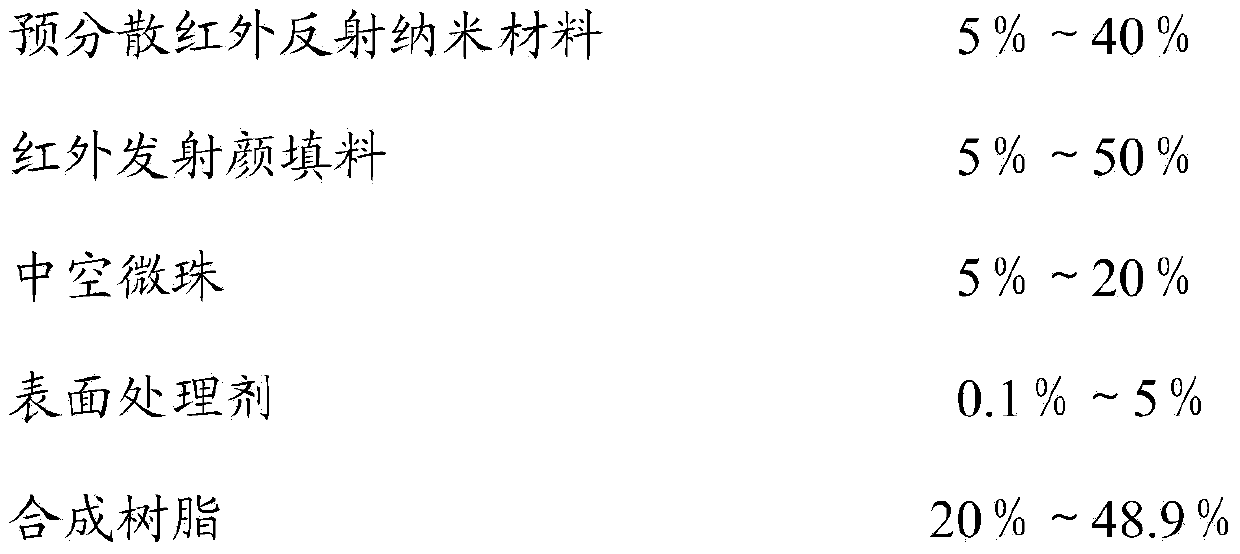

[0029] A functional masterbatch of infrared reflection / emission heat-insulating plastics, comprising 5% of pre-dispersed infrared reflection nanomaterials, infrared emission pigments and fillers (TiO 2 ) 50%, hollow microspheres (hollow ceramic microspheres) 5%, surface treatment agent (stearic acid) 5%, synthetic resin (PE) 30% and additives 5%.

[0030] The method for preparing the infrared reflection / emission heat-insulating plastic functional masterbatch includes the following preparation steps:

[0031] Step A. Infrared reflective nanomaterials are mixed with dispersion medium, wetting agent and dispersant, and then enter into sand mill, ball mill or ultrasonic disperser, after fully dispersed, filter to remove impurities, remove solvent under reduced pressure, and then dry to obtain pre- Disperse infrared reflective nanomaterials;

[0032] Step B. After mixing all the components except the hollow microbeads at a high speed of 1000-1500 rpm for 10-20 minutes, then adding...

Embodiment 2

[0035] An infrared reflective / emissive heat-insulating plastic functional masterbatch, comprising 40% of pre-dispersed infrared reflective nanomaterials, 5% of infrared emitting pigments and fillers (ZnO), 20% of hollow microspheres (hollow glass microspheres), and Surface treatment agent (aluminate coupling agent) 5%, synthetic resin (PMMA) 20% and auxiliary agent 10%.

[0036] The method for preparing the infrared reflective / emissive heat-insulating plastic functional masterbatch is the same as that in Example 1.

Embodiment 3

[0038] A functional masterbatch of infrared reflection / emission heat-insulating plastics, comprising 10% of pre-dispersed infrared reflection nanomaterials, infrared emission pigments and fillers (Al 2 o 3 ) 25%, hollow microspheres (hollow ceramic microspheres 5% and hollow glass microspheres 10%) 15%, surface treatment agent (titanate coupling agent) 0.1%, synthetic resin (ABS) 48.9% and additives 1 %.

[0039] The method for preparing the infrared reflective / emissive heat-insulating plastic functional masterbatch is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com