Patents

Literature

35results about How to "To achieve the purpose of supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength thin band steel for cold forming and manufacturing method thereof

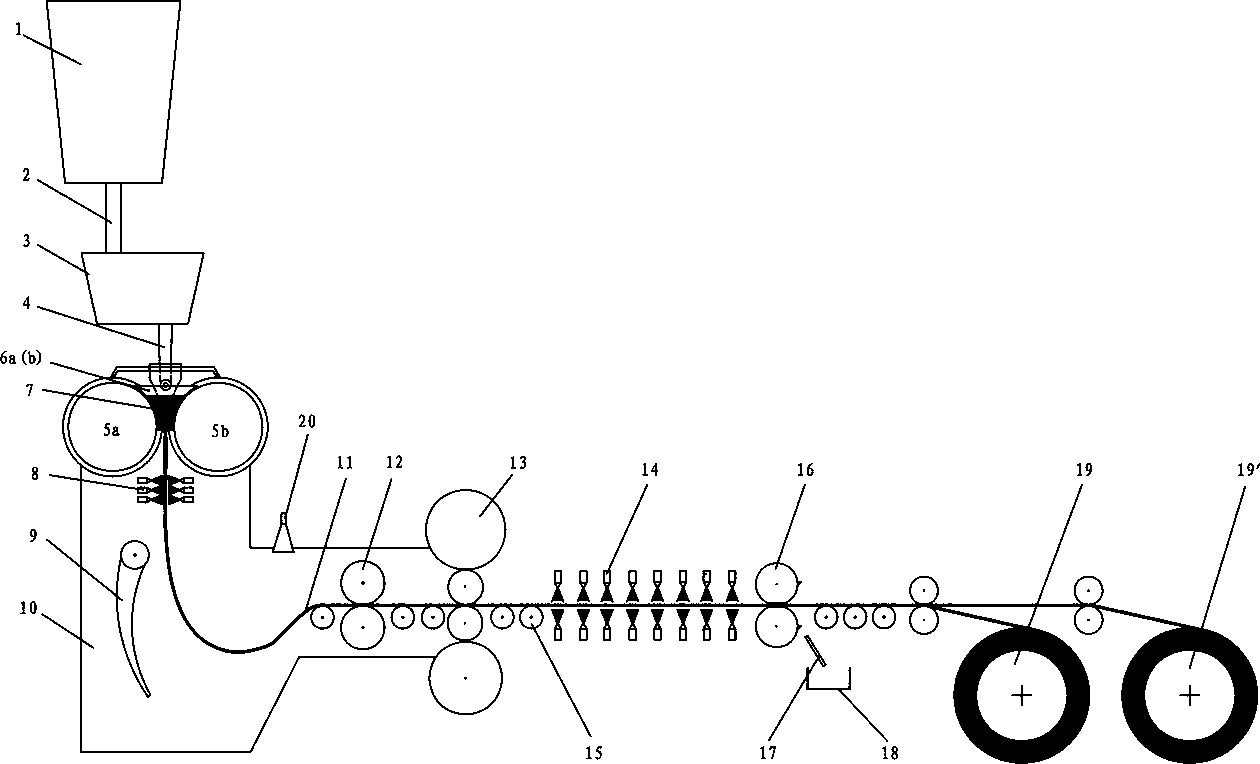

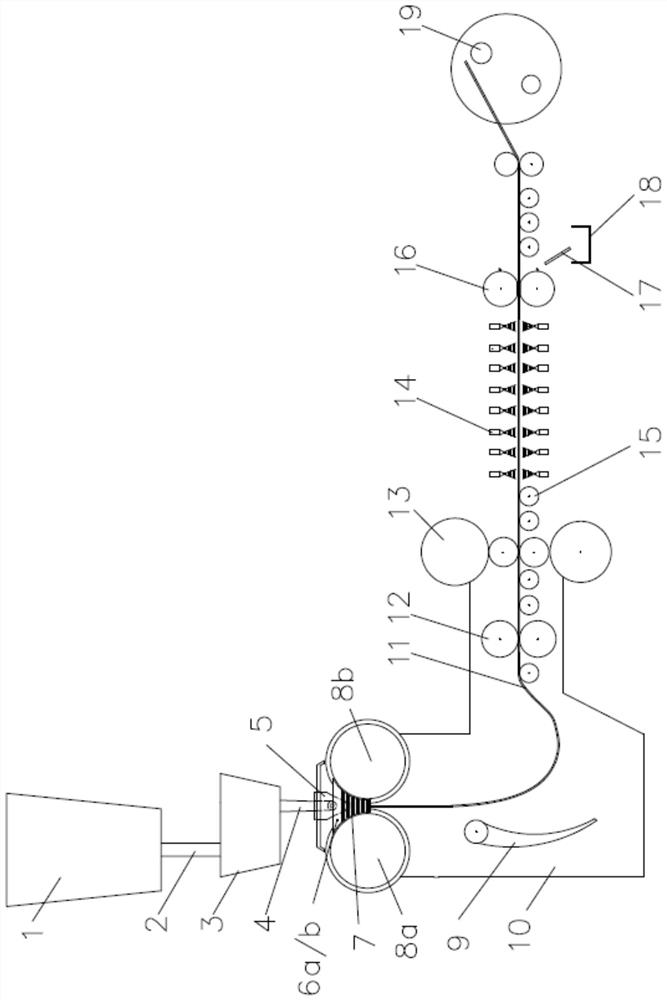

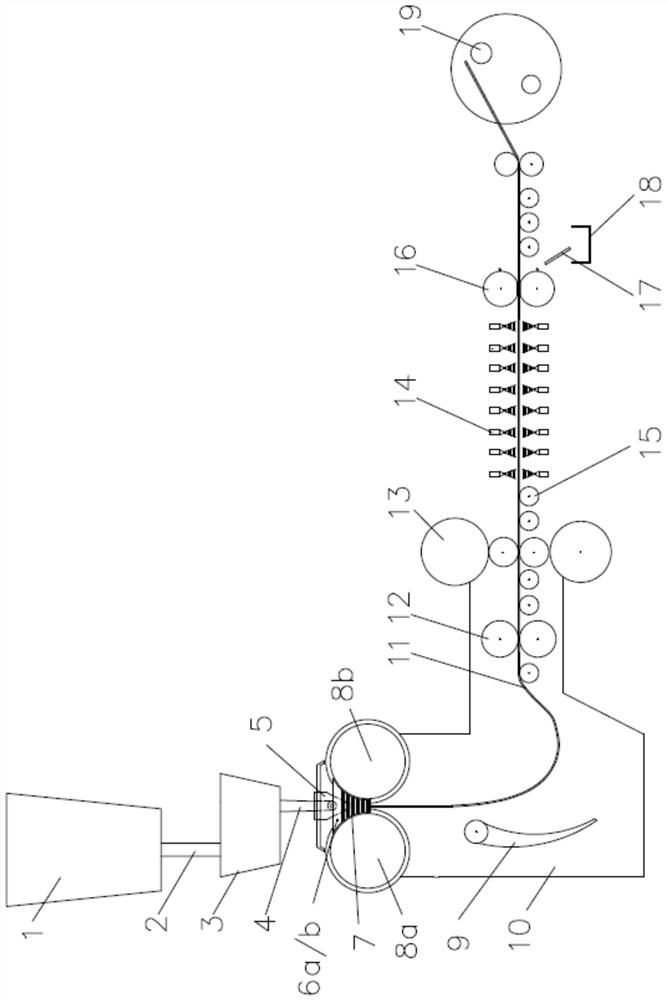

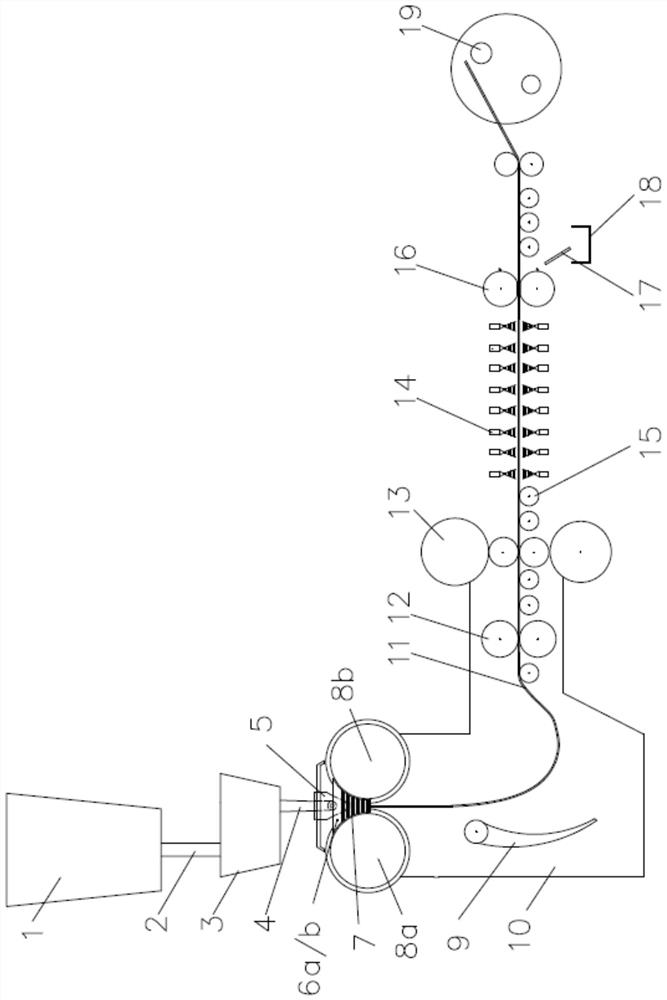

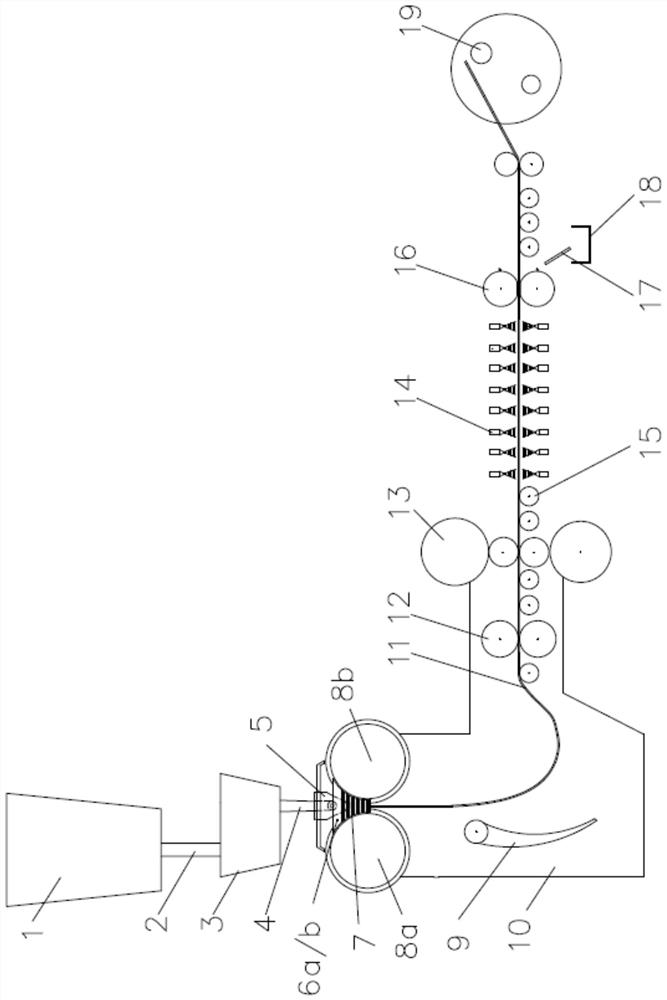

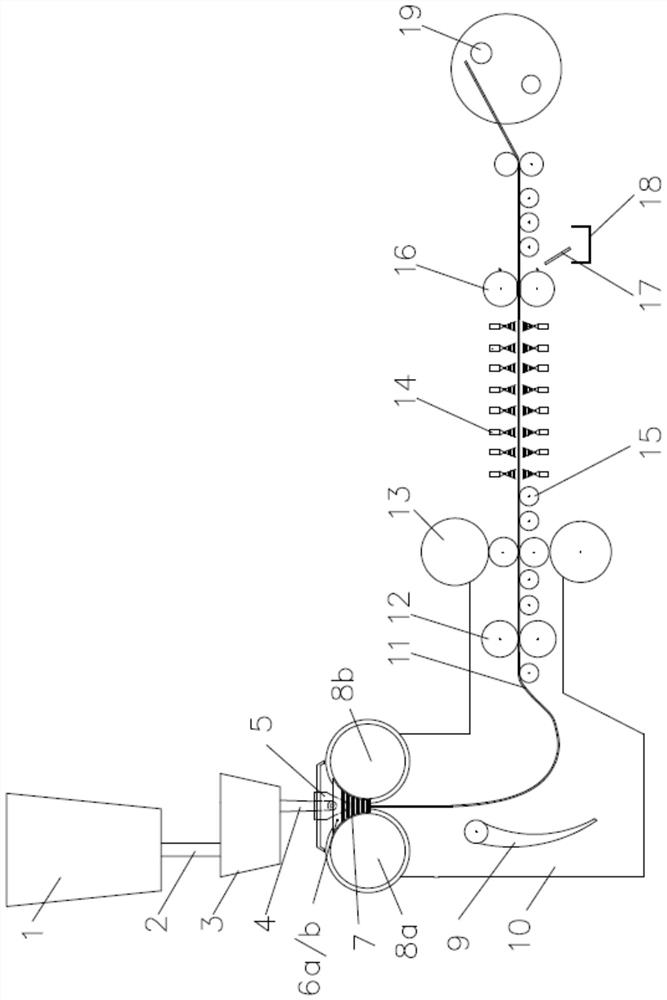

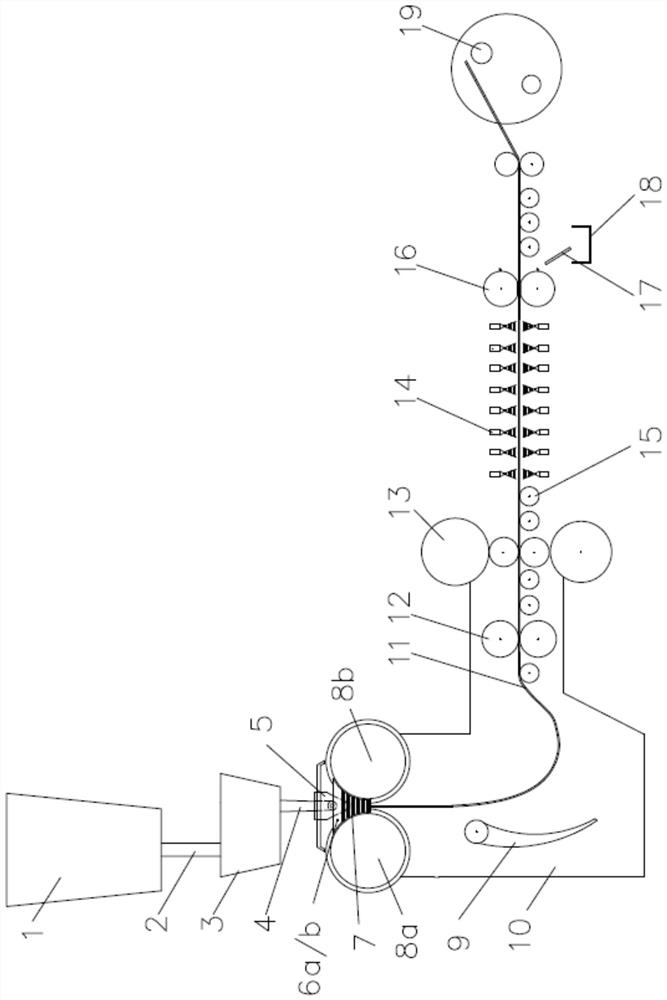

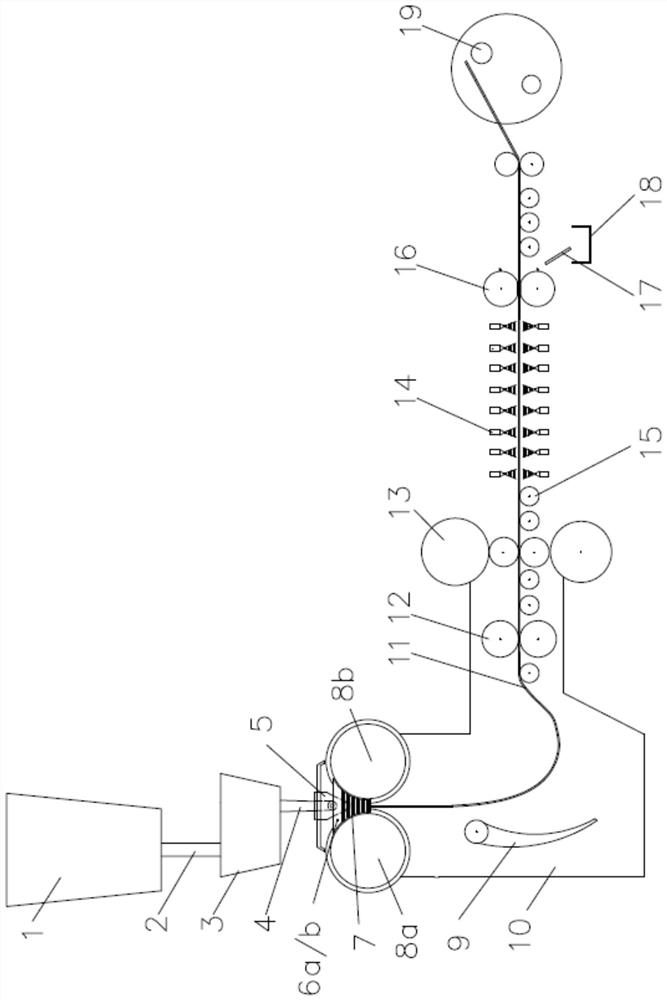

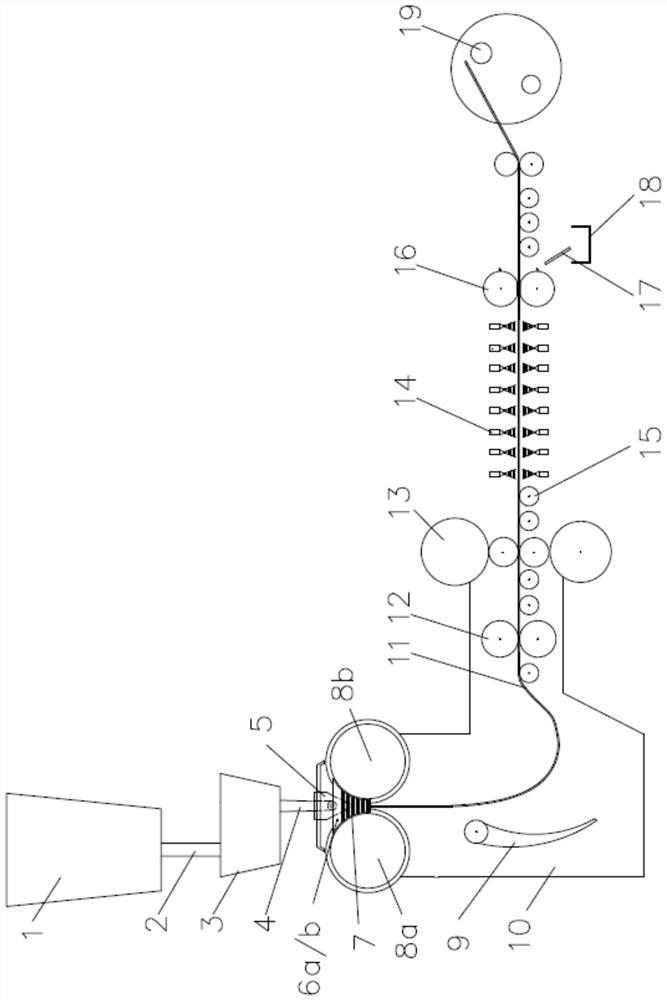

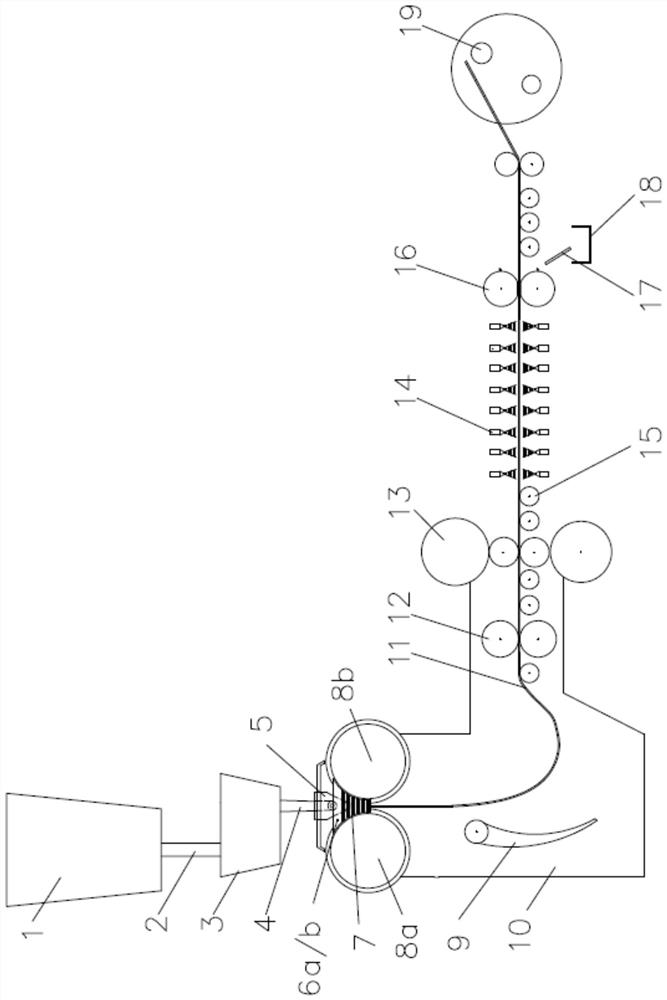

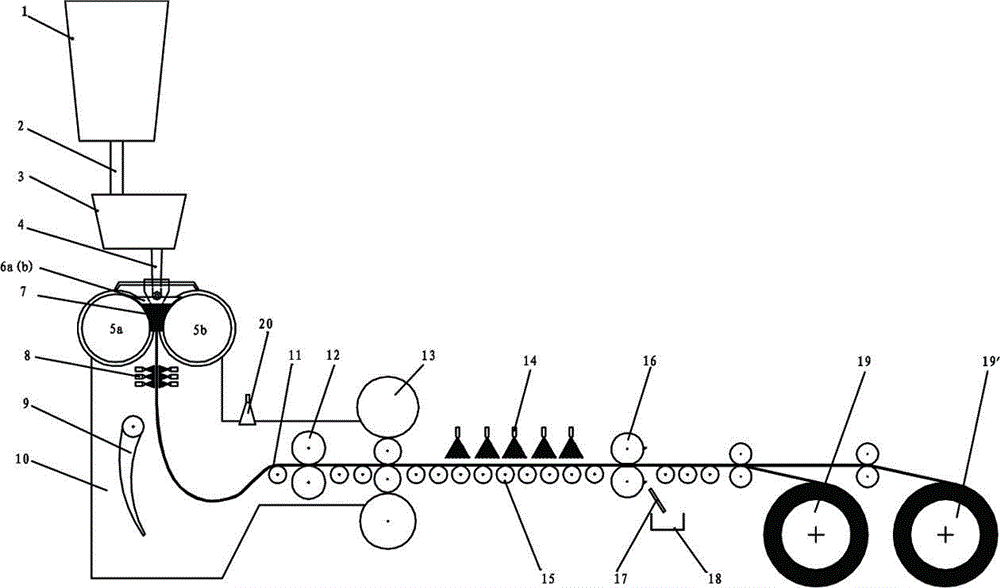

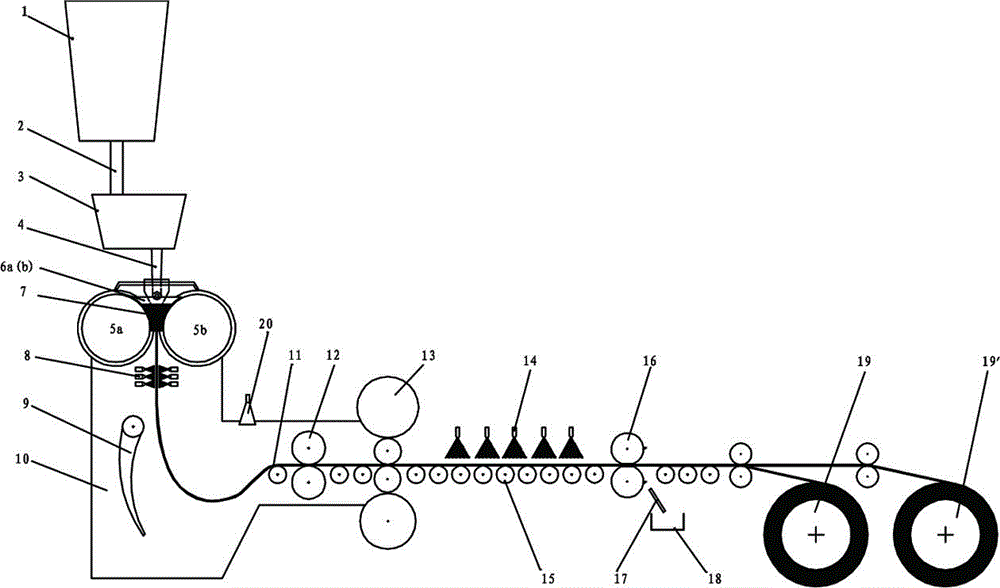

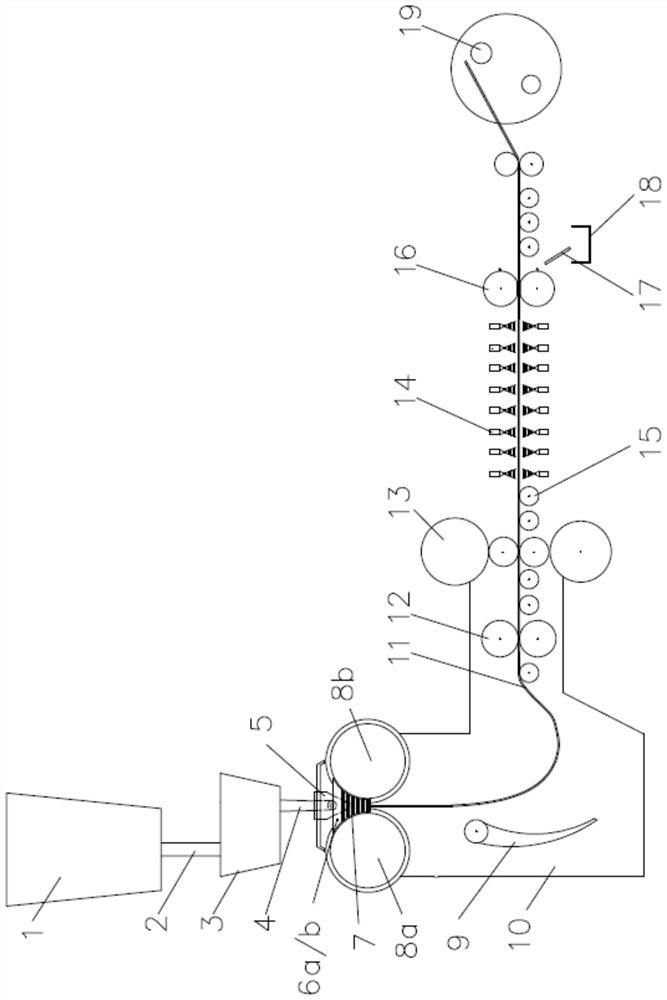

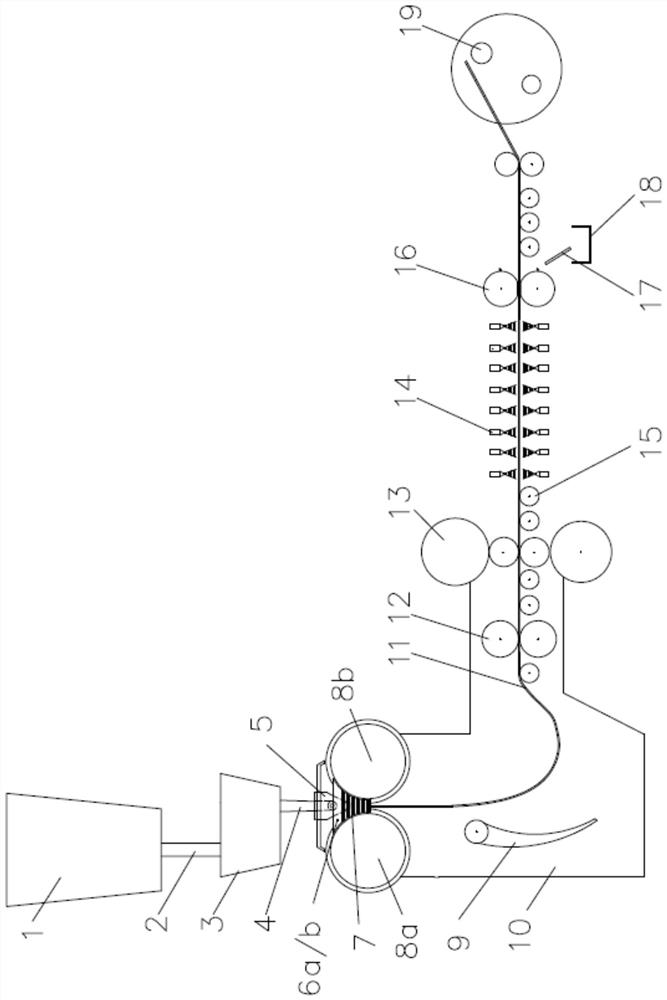

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength thin strip steel for cold forming and manufacturing method thereof

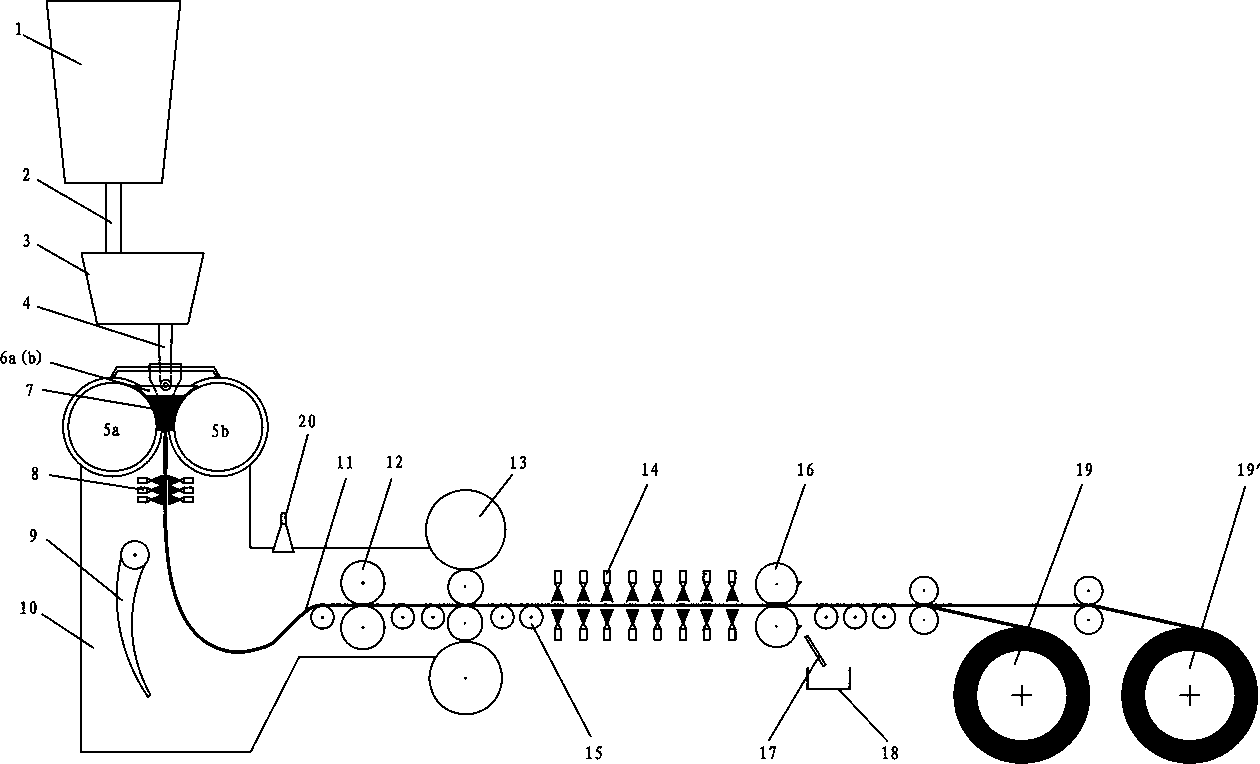

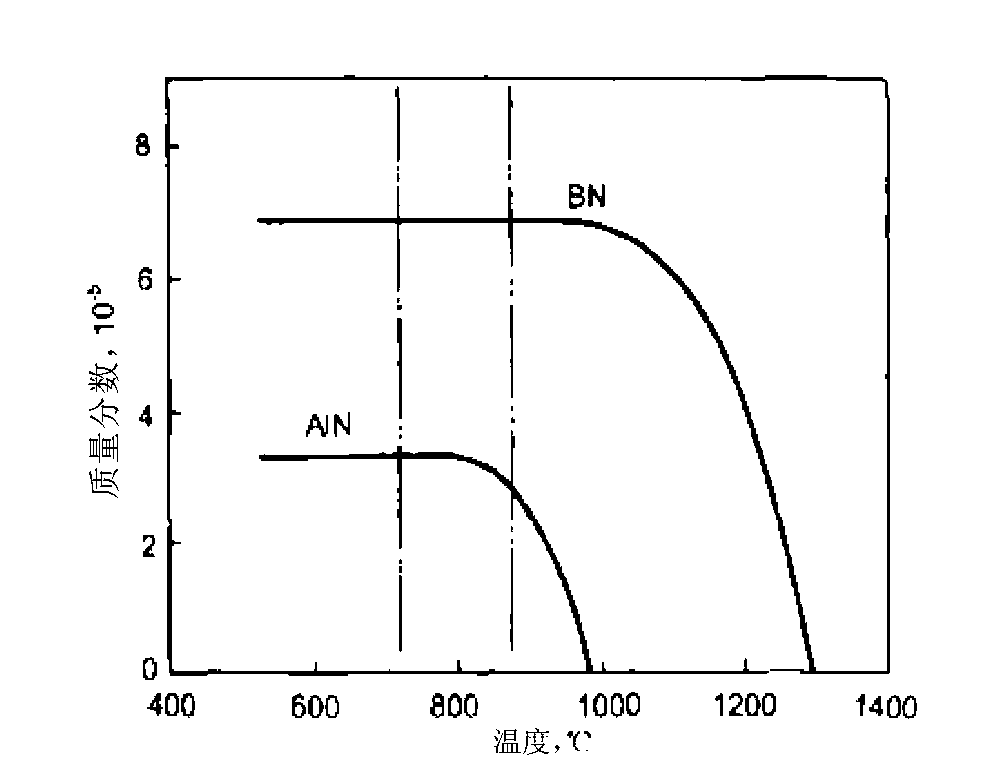

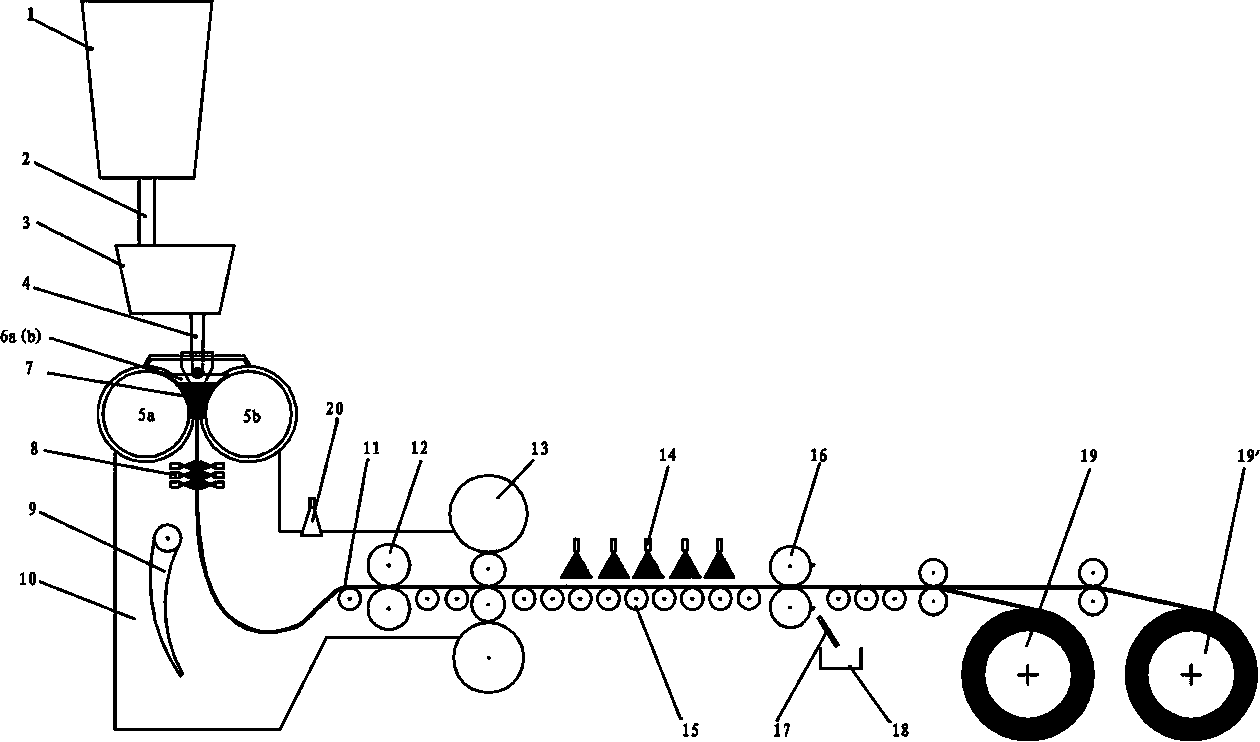

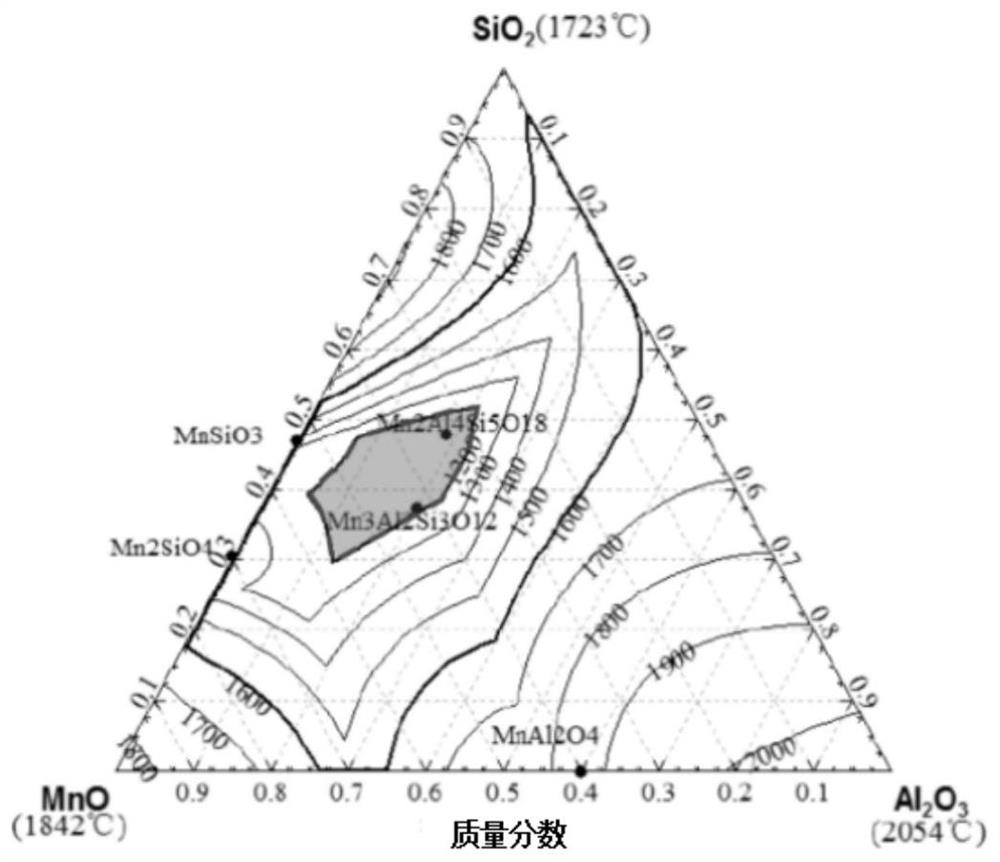

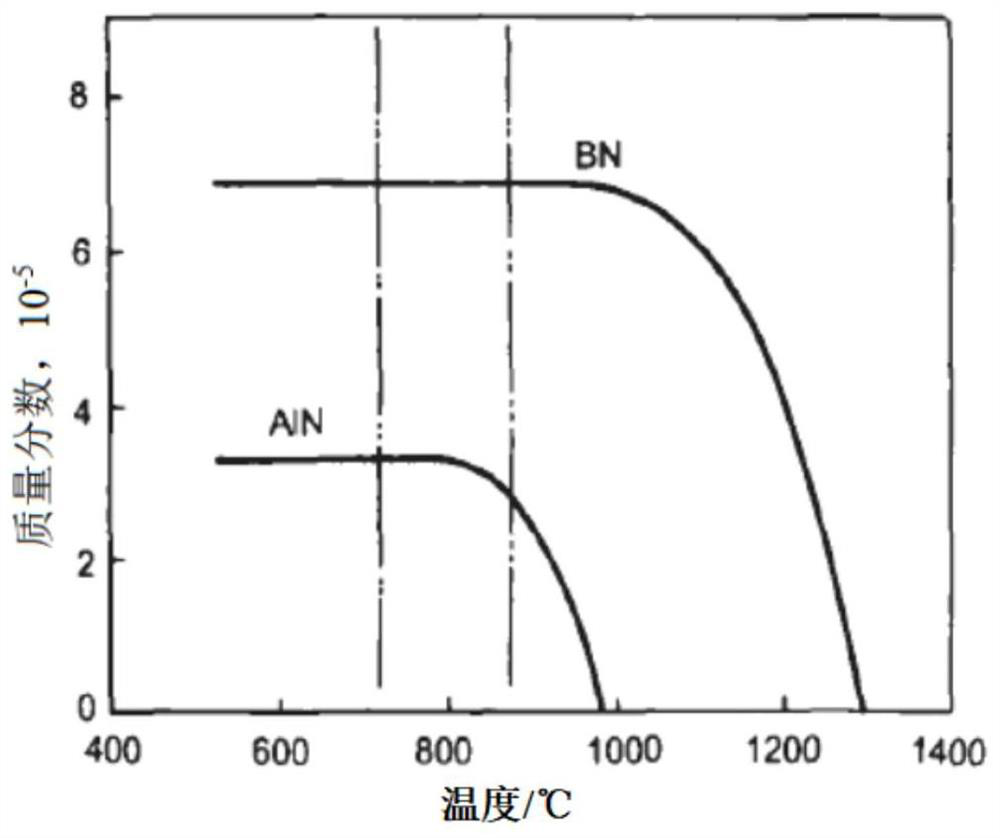

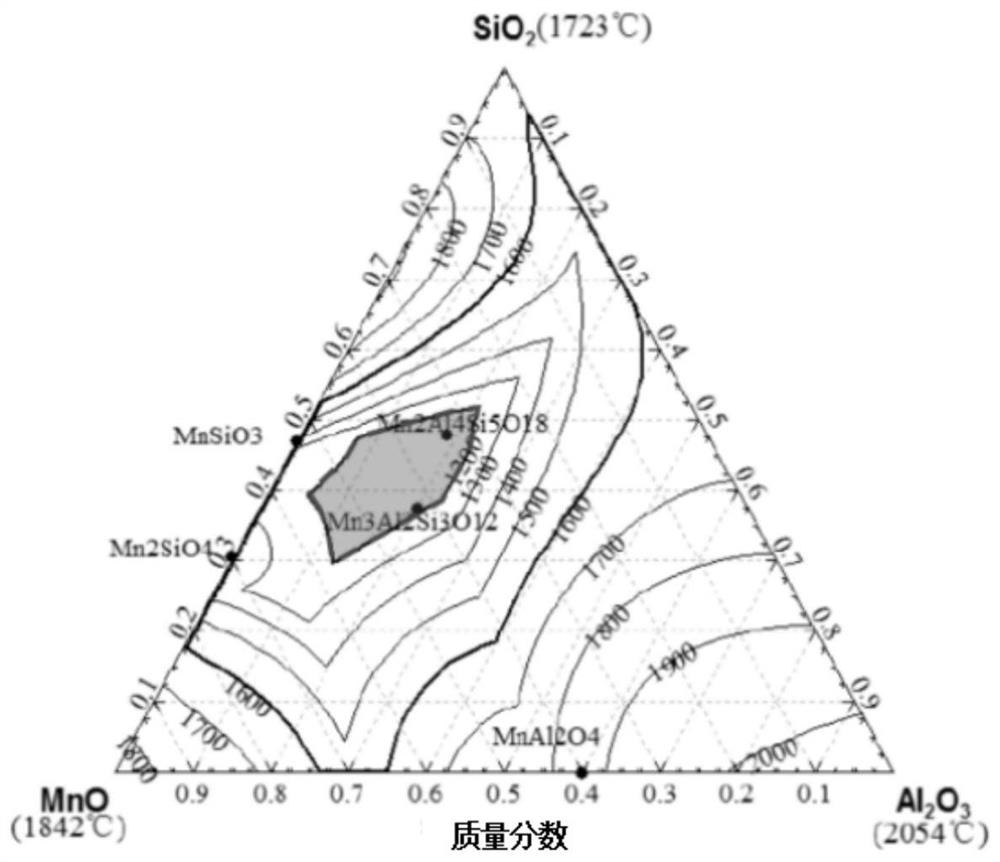

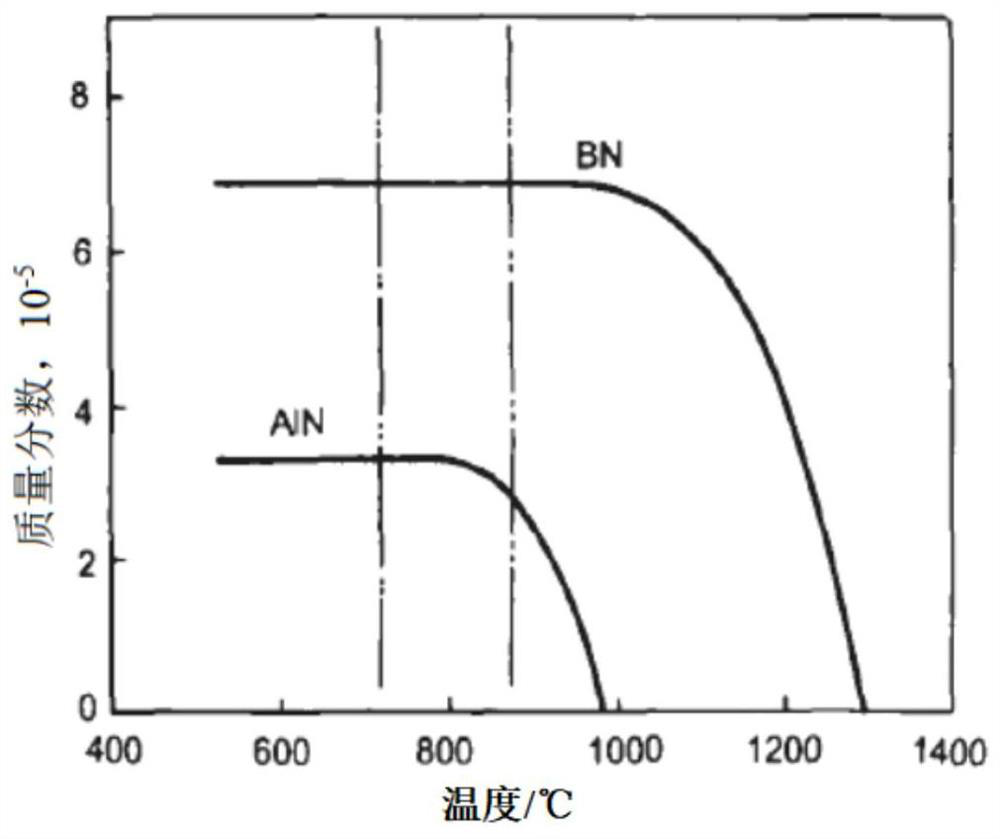

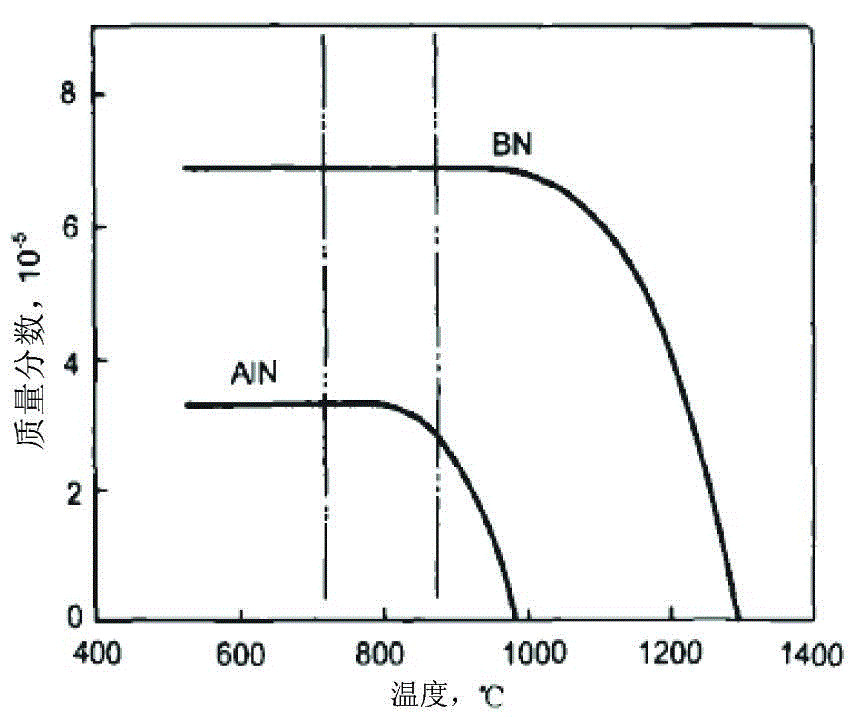

ActiveCN103667895ATo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideHigh pressure

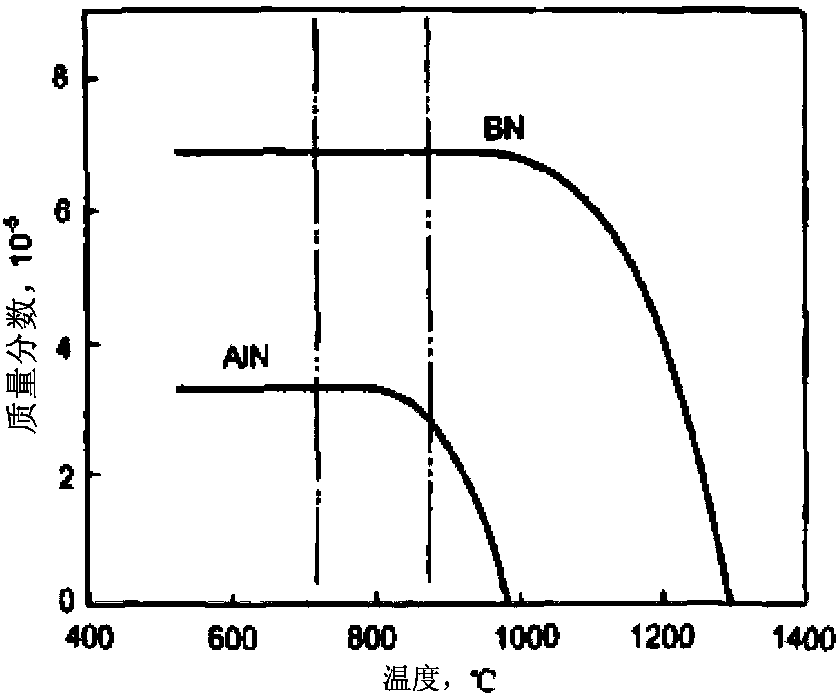

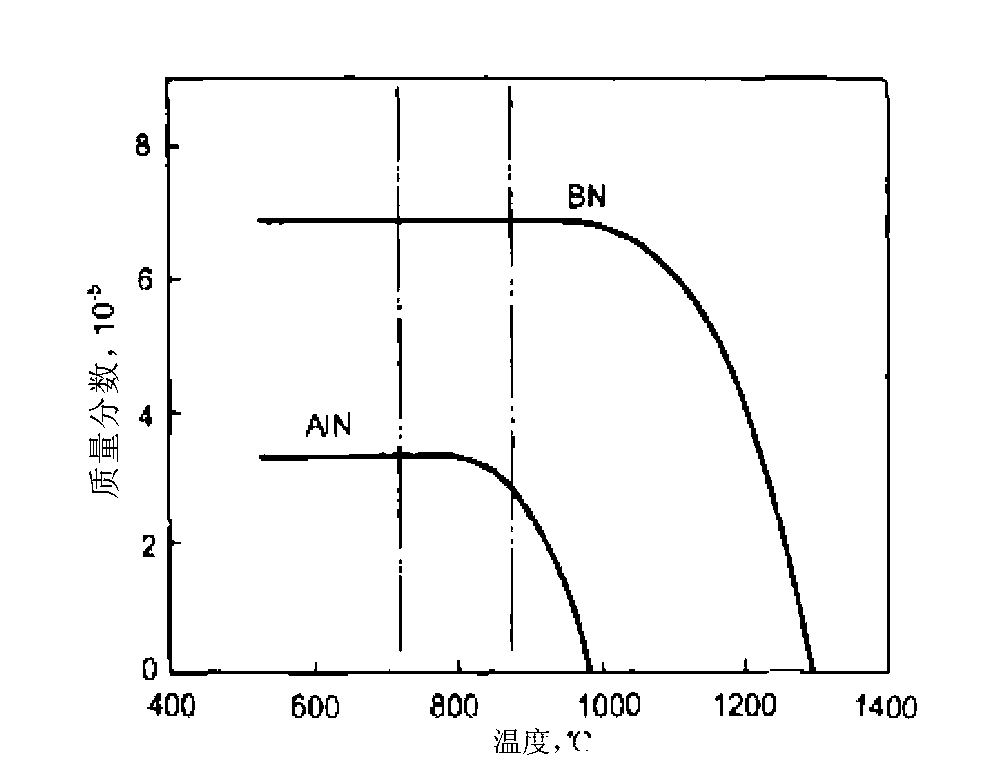

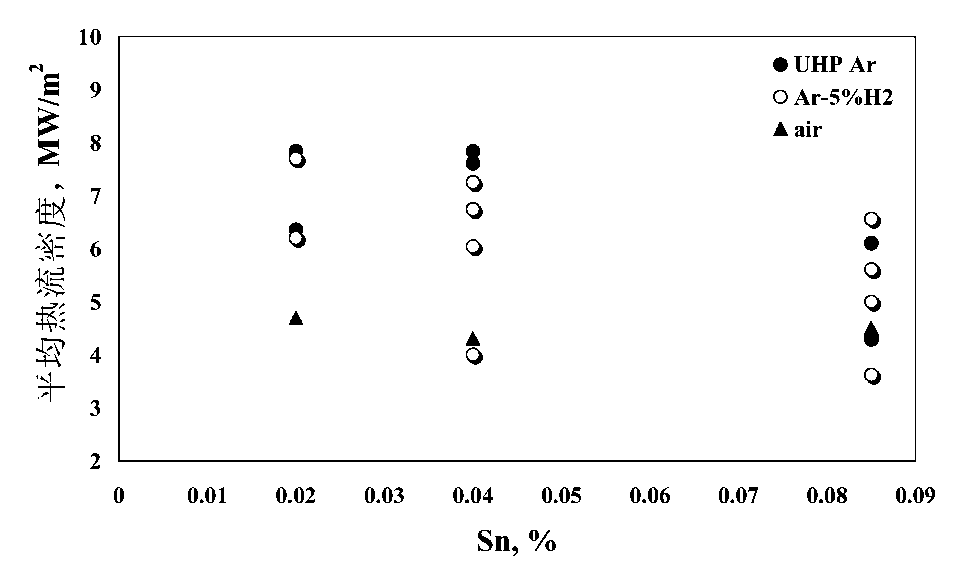

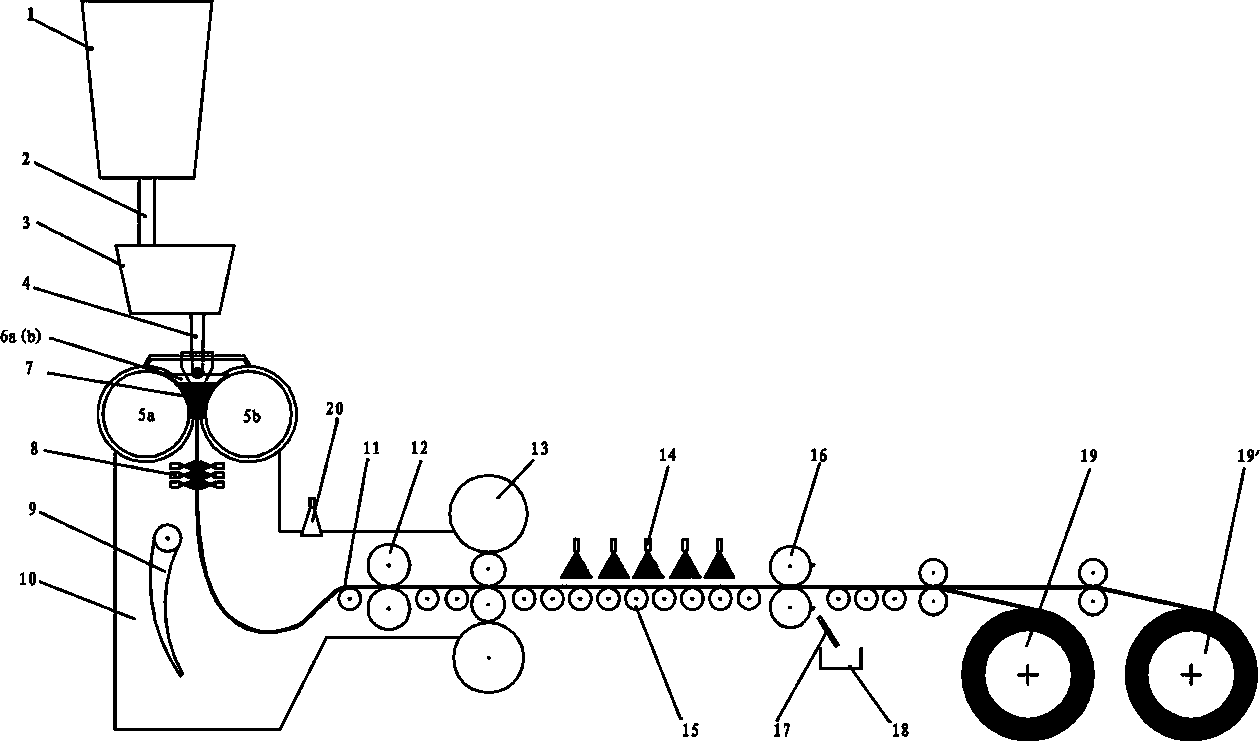

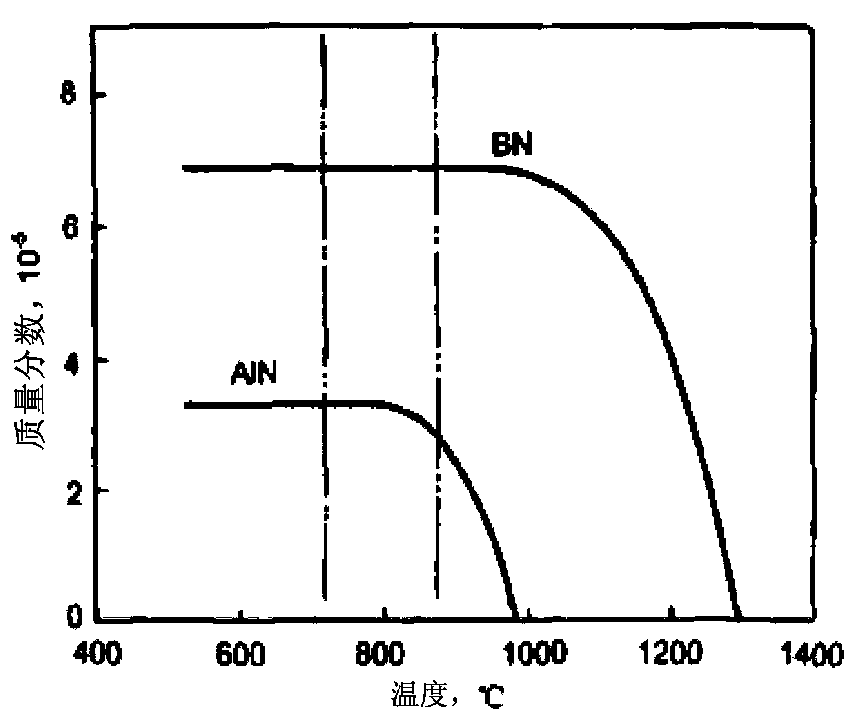

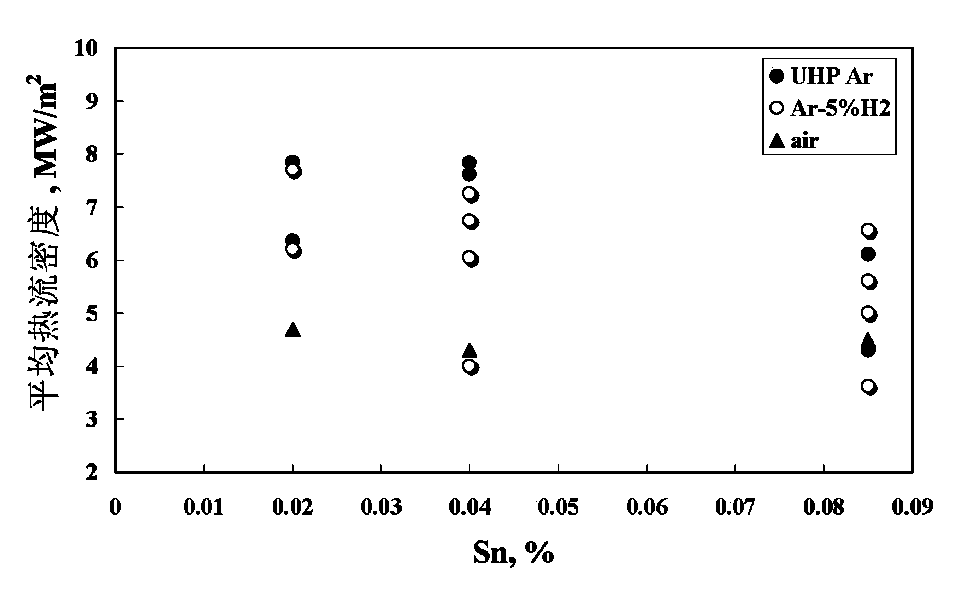

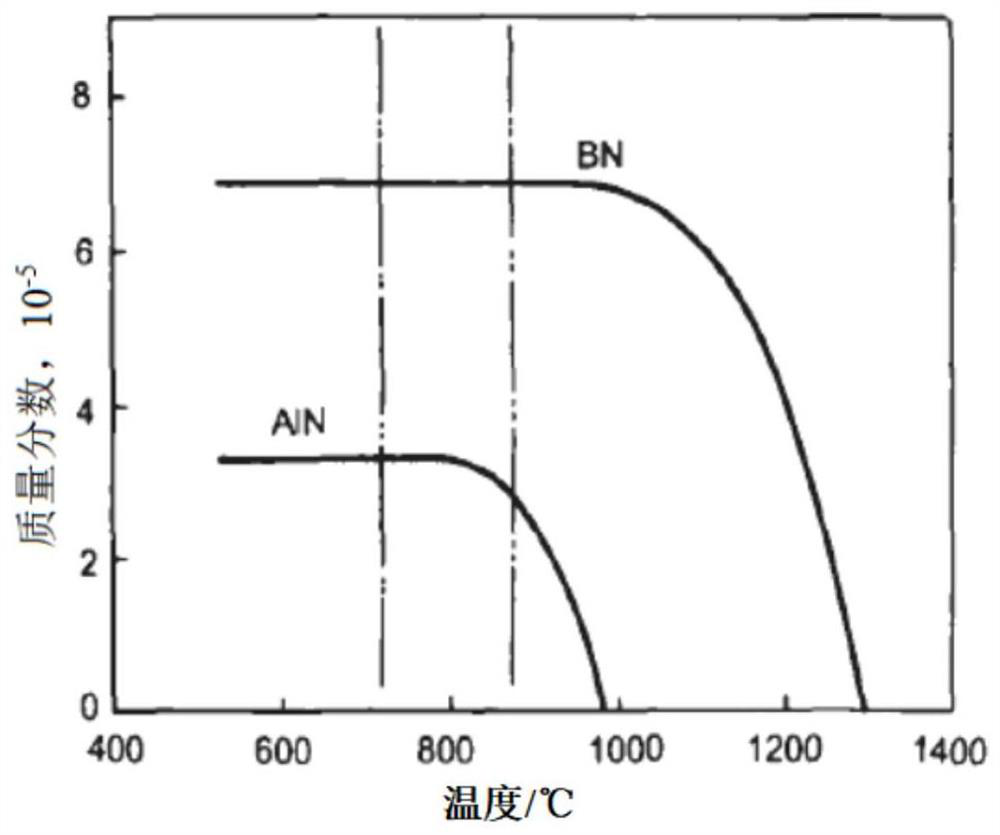

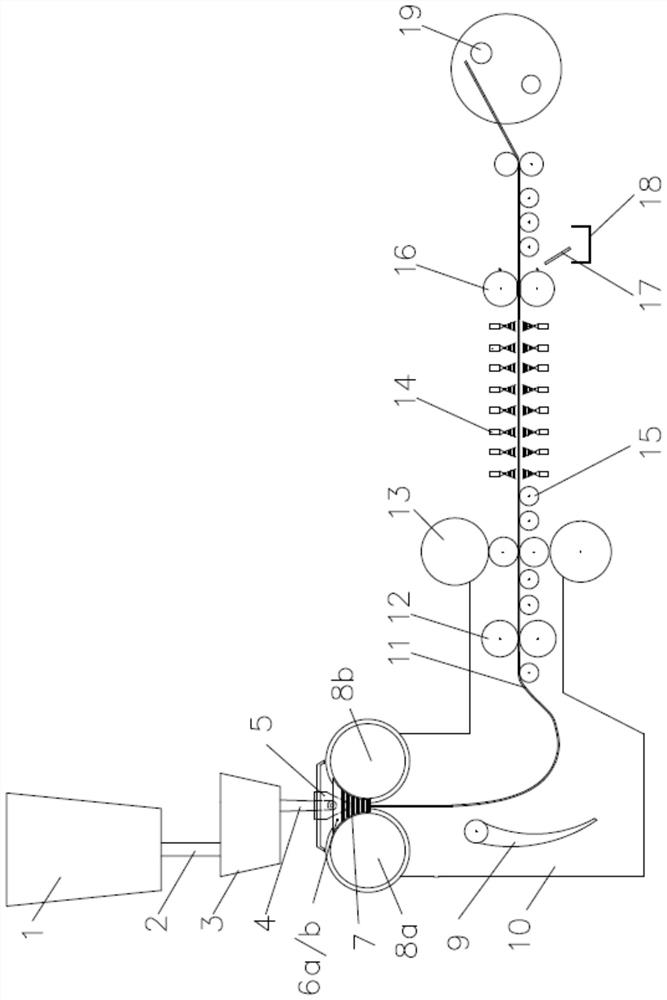

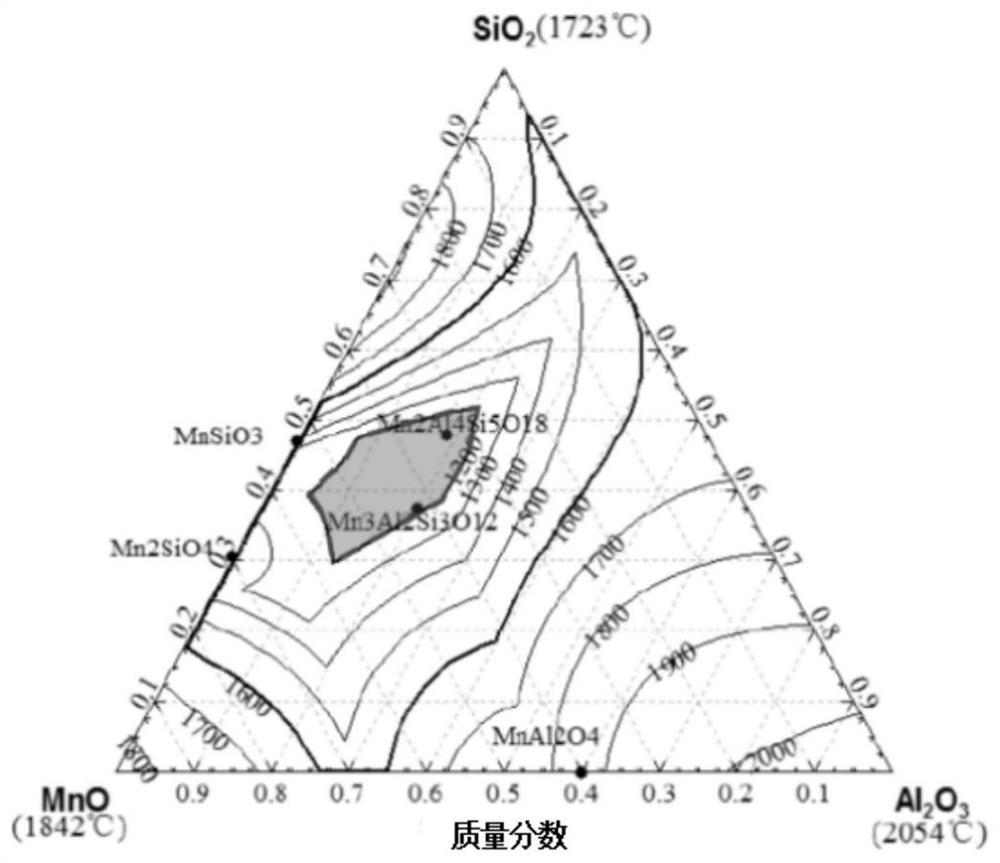

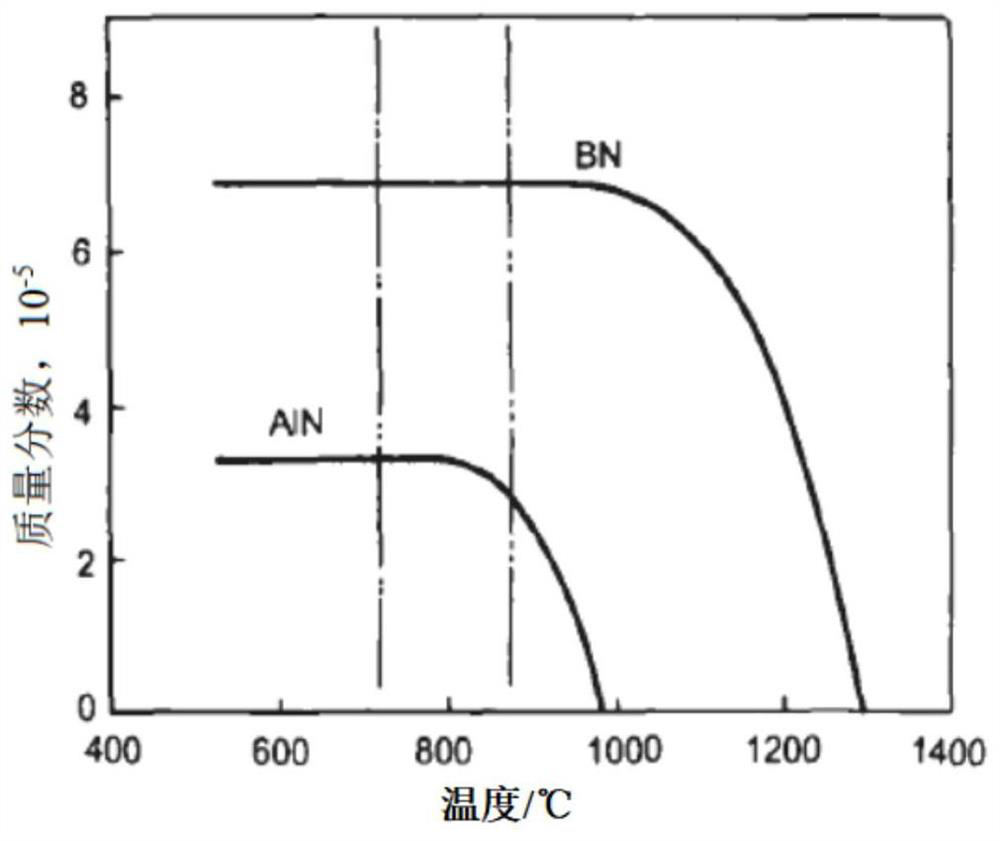

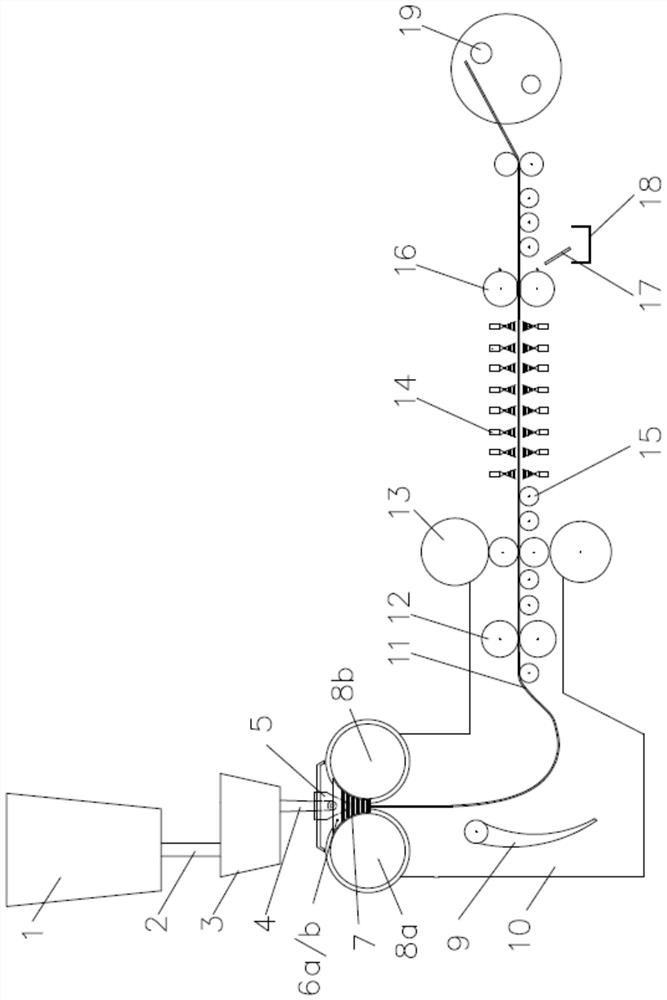

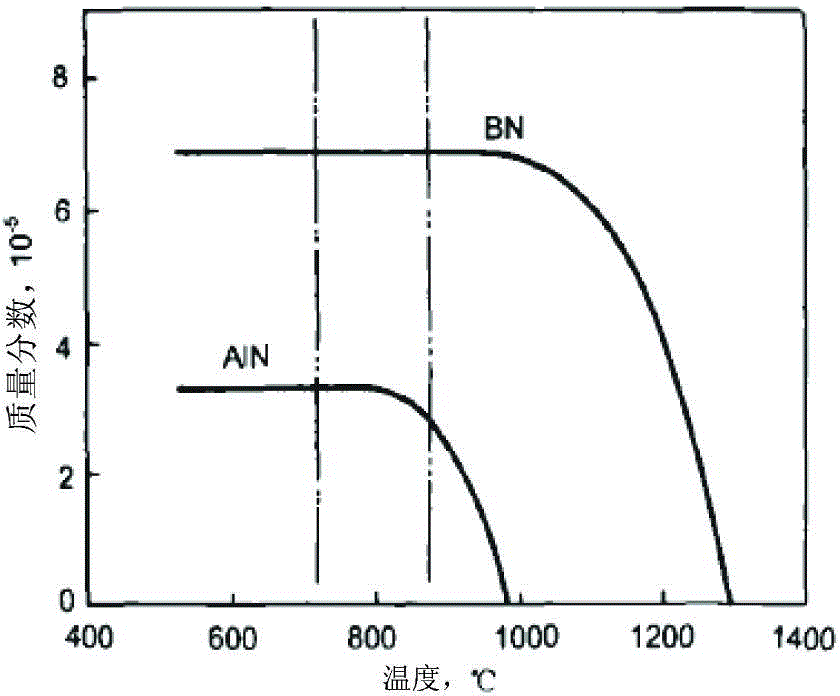

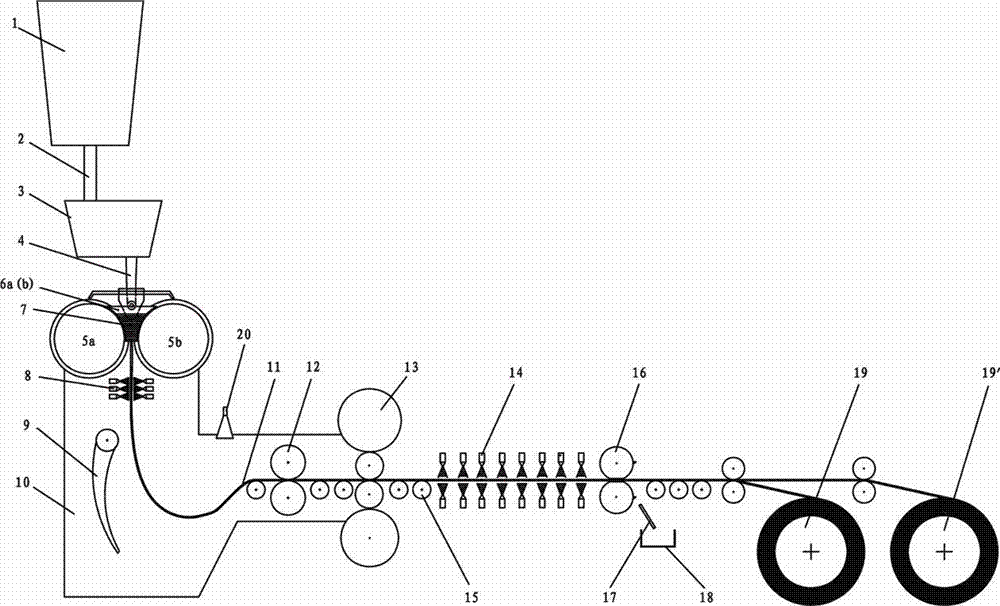

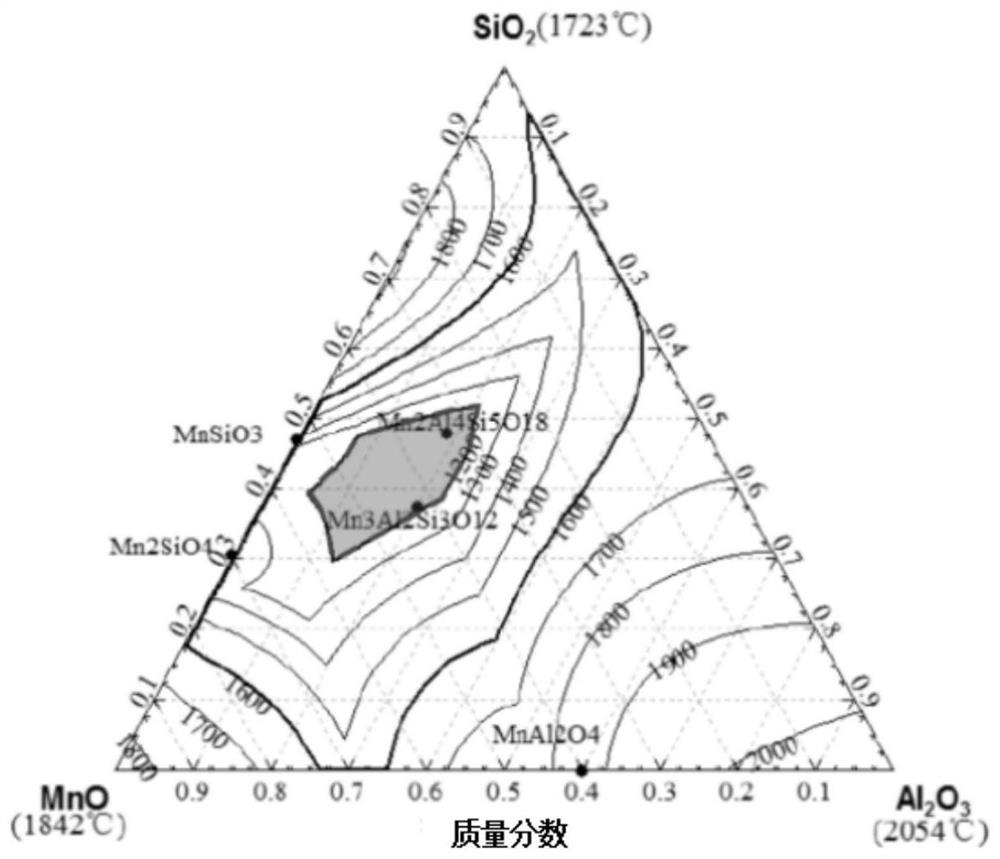

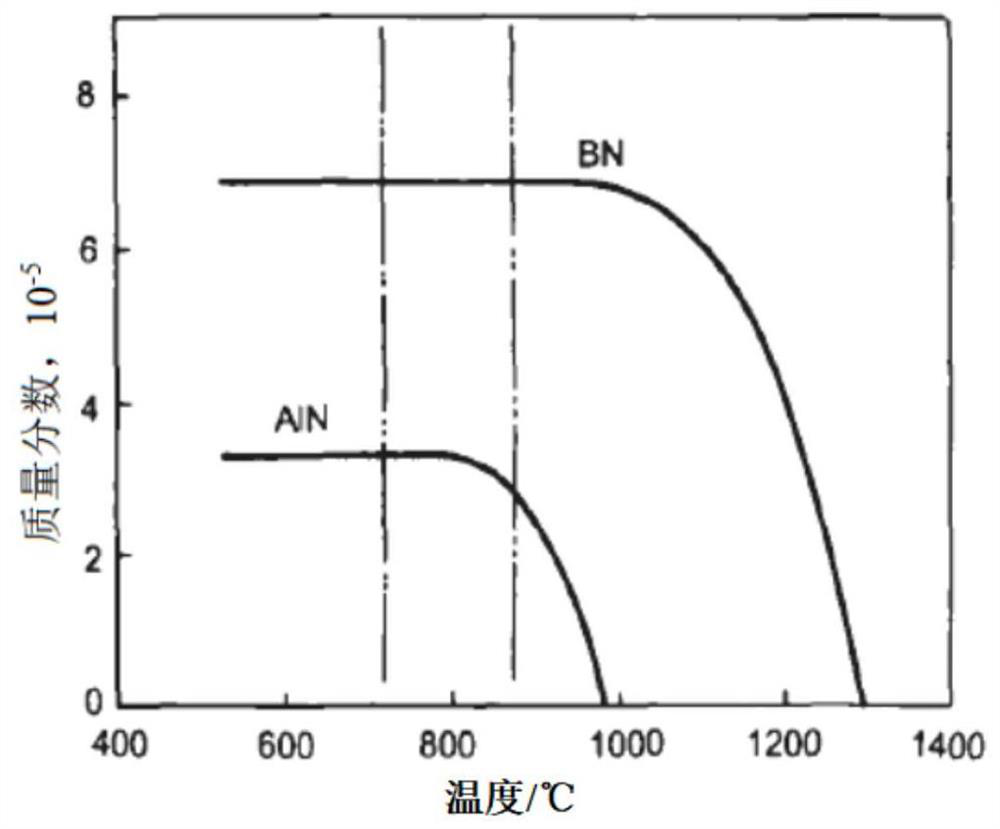

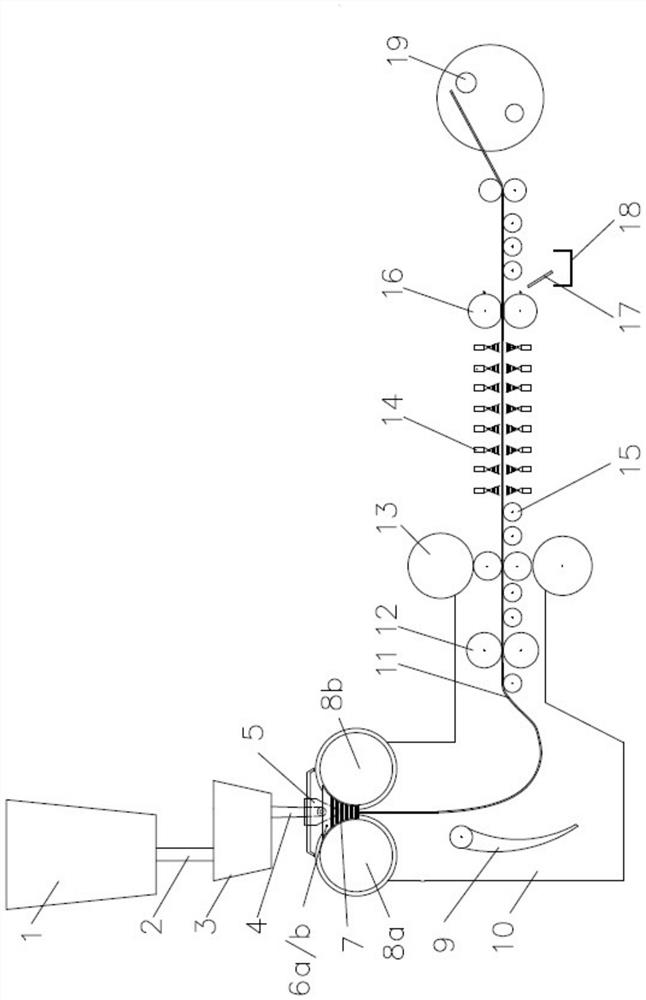

The invention relates to high-strength thin strip steel for cold forming and a manufacturing method thereof. The manufacturing method comprises the following steps: performing uniform enhanced cooling on a cast strip by adopting a high-pressure dry ice spraying way after the cast strip is discharged from a crystallization roller, thus rapidly cooling the cast strip to below 1280 DEG C, wherein the cooling rate is 200-300 DEG C / s, and by adopting the cooling way of the strip steel after boron treatment, the precipitation of coarse BN (boron nitride) can be promoted, the appearance of low-melting point phase B2O3 and the precipitation of fine AlN can be prevented and the purposes of uniformizing austenite grains and reducing yield ratio are achieved; then performing austenite online recrystallization rolling; cooling the strip steel after hot rolling by atomization cooling, wherein the cooling rate of atomization cooling is 10-70 DEG C / s; coiling at the temperature of 650-750 DEG C. Through the manufacturing method provided by the invention, the high-strength thin strip steel for cold forming of an automobile, which has relatively low yield ratio and excellent stamping performance, can be obtained. The high-strength hot-rolled thin strip steel for cold forming, which is produced by the method, can be directly used for replacing cold-rolled steel with the hot-rolled steel, cancel a cold rolling process step and greatly reduce production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin strip steel for thin-wall oil drum and manufacturing method of thin strip steel

ActiveCN102796943ATo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideYield ratio

The invention discloses a thin strip steel for a thin-wall oil drum and a manufacturing method of the thin strip steel. Double-roll thin strip continuous production is adopted; a dry ice spray mode is adopted after a cast strip is discharged from a crystallization roll; uniform enhanced cooling is performed on the cast strip; the cast strip is quickly cooled to be below 1,280 DEG C; the cooling rate is 200-300 DEG C / s; in such a cooling mode, separation of coarse BN (Boron Nitride) can be promoted and low-melting-point phase B2O3 and fine AlN (Aluminum Nitride) separation are prevented to fulfill the aims of uniformizing austenite crystal grains and reducing the yield ratio; and then austenite is recrystallized and rolled on line, and the strip steel which is subjected to hot rolling is cooled through anti-oxidation quick cooling, wherein the cooling rate is 80-200 DEG C / s and the coiling temperature is 500-600 DEG C. Through the invention, the thin strip steel for the thin-wall oil drum with low yield ratio and superior impact performance can be obtained. According to the thin strip steel for the thin-wall oil drum produced by the method, the hot thin strip steel can be directly used in place of a cold one, a cold rolling step is removed, and the production cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel strip for thin-wall oil bucket and manufacturing method thereof

The invention discloses a steel strip for a thin-wall oil bucket and a manufacturing method thereof. The manufacturing method comprises the following steps: casting a crystal roller from a cast strip by using a thin strip casting process, subsequently uniformly reinforcing and cooling the cast strip in a mode that dry ice is sprayed at a high pressure, and rapidly cooling the cast strip to be less than 1,280 DEG C, wherein the cooling velocity is 200-300 DEG C / s; when the steel strip is subjected to boron treatment in such a mode, large boron nitride separation is prompted, occurrence of low-melting-point phase B2O3 and separation of fine AlN are prevented, and the purposes of uniformly austenite grains and reducing the yield ratio are achieved; subsequently performing on-line recrystallization and rolling on the austenite; subsequently atomizing and cooling so as to cool down the hot-rolled steel strip; finally coiling the steel strip. By adopting the manufacturing method, the thin-wall with low yield ratio and excellent stamping property for the thin-wall oil bucket is manufactured. The hot-rolled steel strip for the thin-wall oil bucket can be used in hotness instead of coldness, and a cold-rolling procedure is omitted, so that the production cost is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

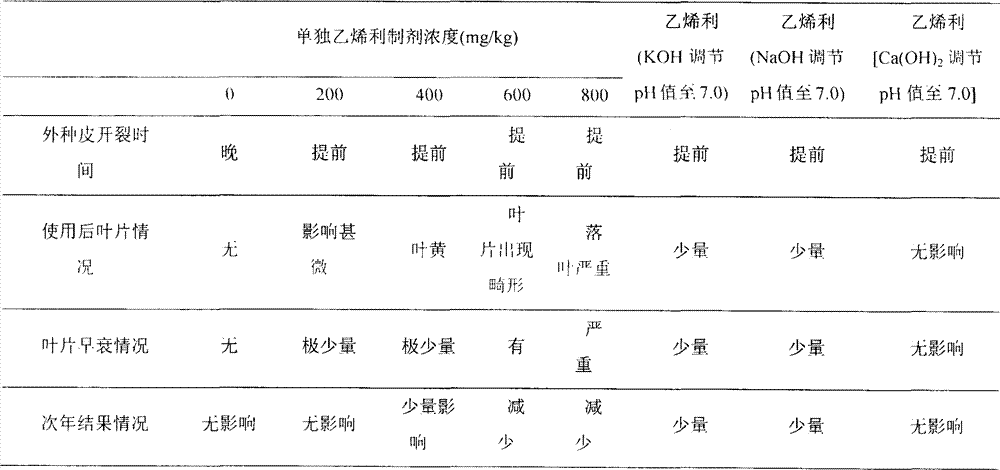

Harvesting and processing method of Carya illinoensis

The invention discloses a harvesting and processing method of Carya illinoensis. The method includes the following steps that an ethephon preparation with concentration of 200 mg / kg is sprayed to bearing branches for one time four weeks before harvesting of the Carya illinoensis, and Ca(OH)2 is used for adjusting a power of hydrogen (PH) value to be 7.0; when the ethephon preparation is sprayed for two weeks and 70% of fruit episperm is cracked, the Carya illinoensis is harvested; deadwood and sundries under trees are cleared away, and a black mesh fabric is spread; a machine shakes the bearing branches, fruits falling on the mesh fabric are timely collected, sundries are removed, episperm which is not cracked is removed in a huller, and the fruits are washed by running water; and rinsing, ozone disinfection and drying with a drying machine are performed so that moisture contents of the fruits are lower than 4.3%, and storage is finally performed. By means of the harvesting and processing method, fruit maturity periods of the Carya illinoensis can be unified, natural fruit drop is reduced, a launch date of the fruits is shifted to be earlier, output is improved, fruit cracking and fruit color changing caused by solarization are avoided, and qualities of the fruits are improved so that selling prices of the Carya illinoensis are effectively increased.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

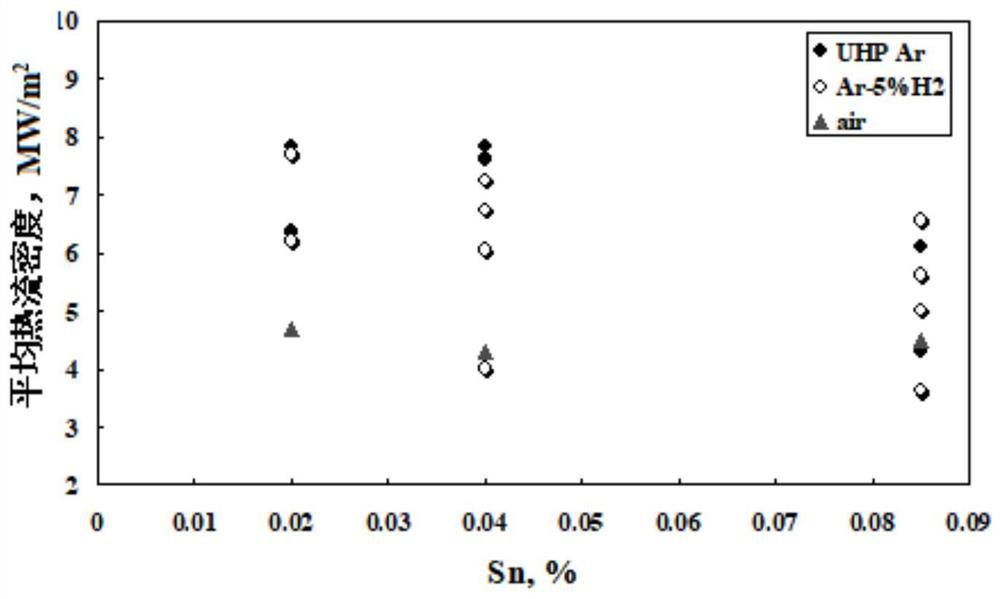

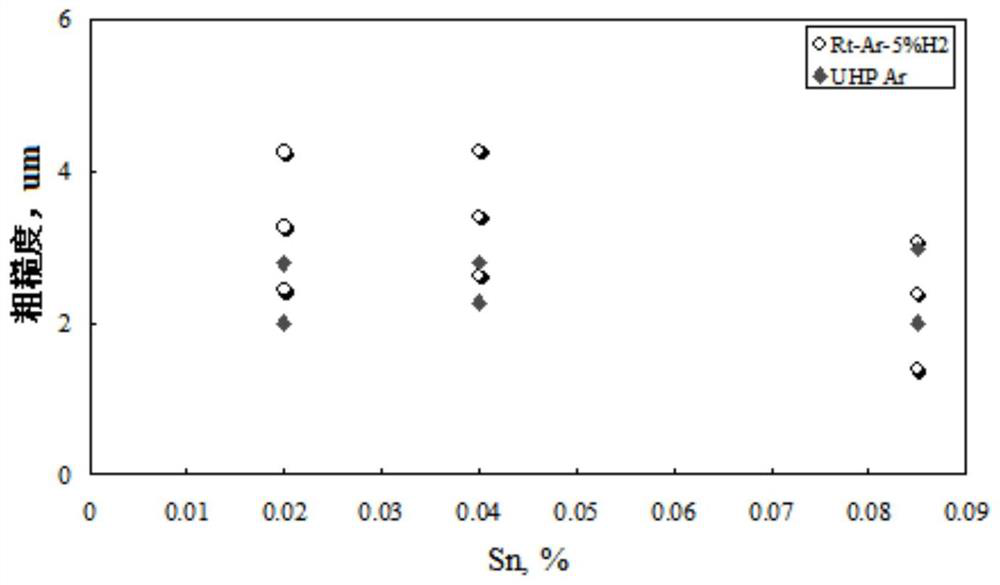

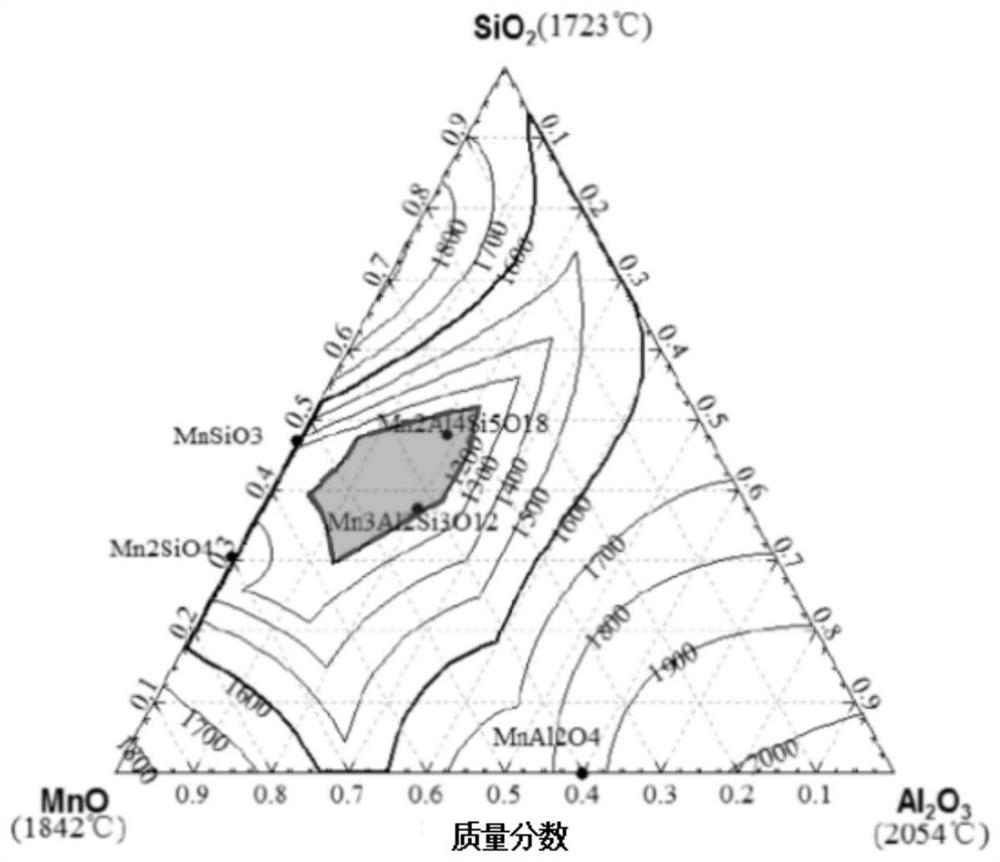

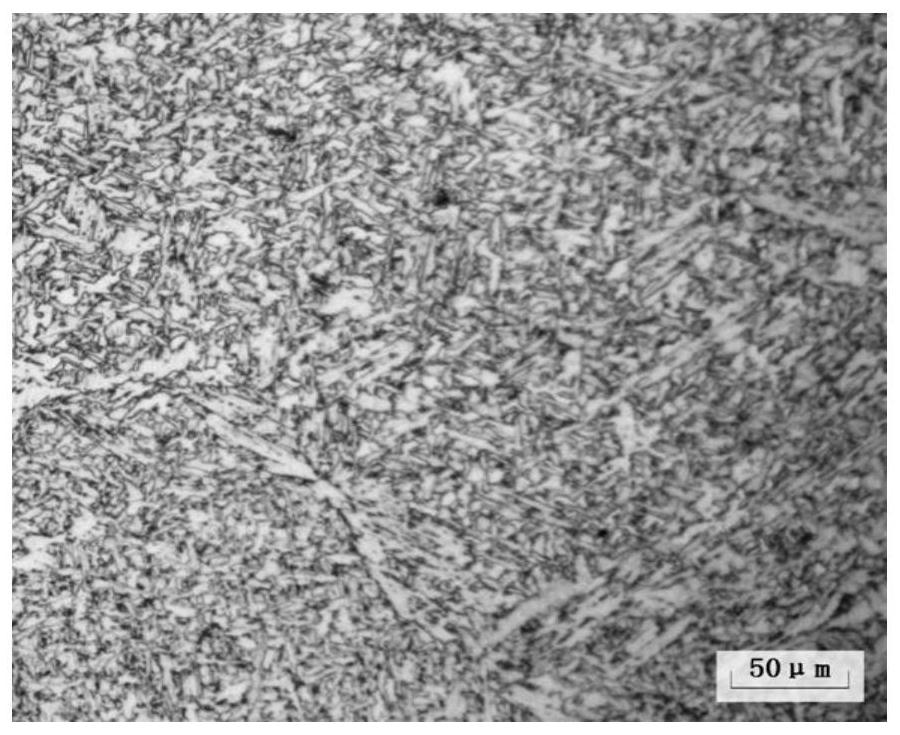

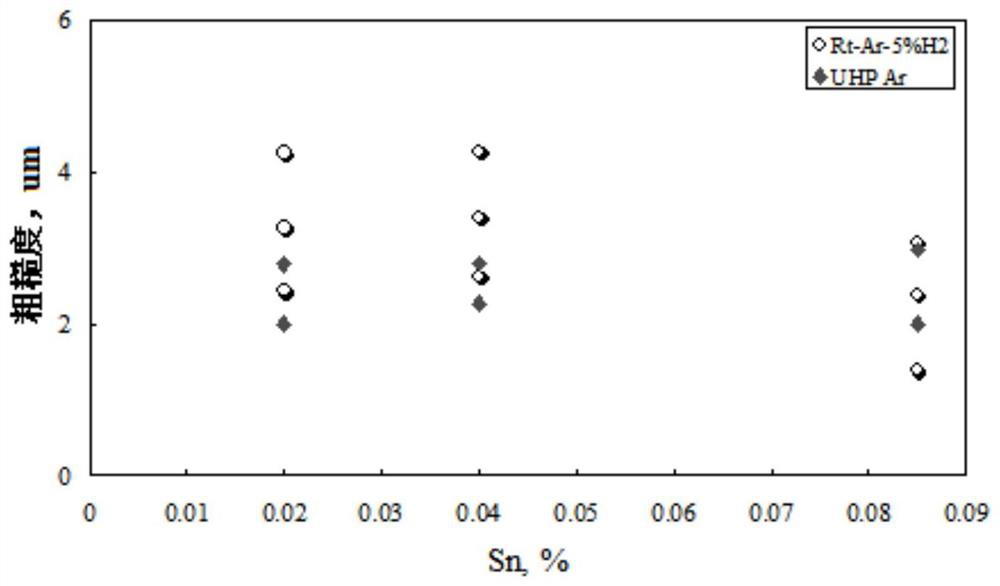

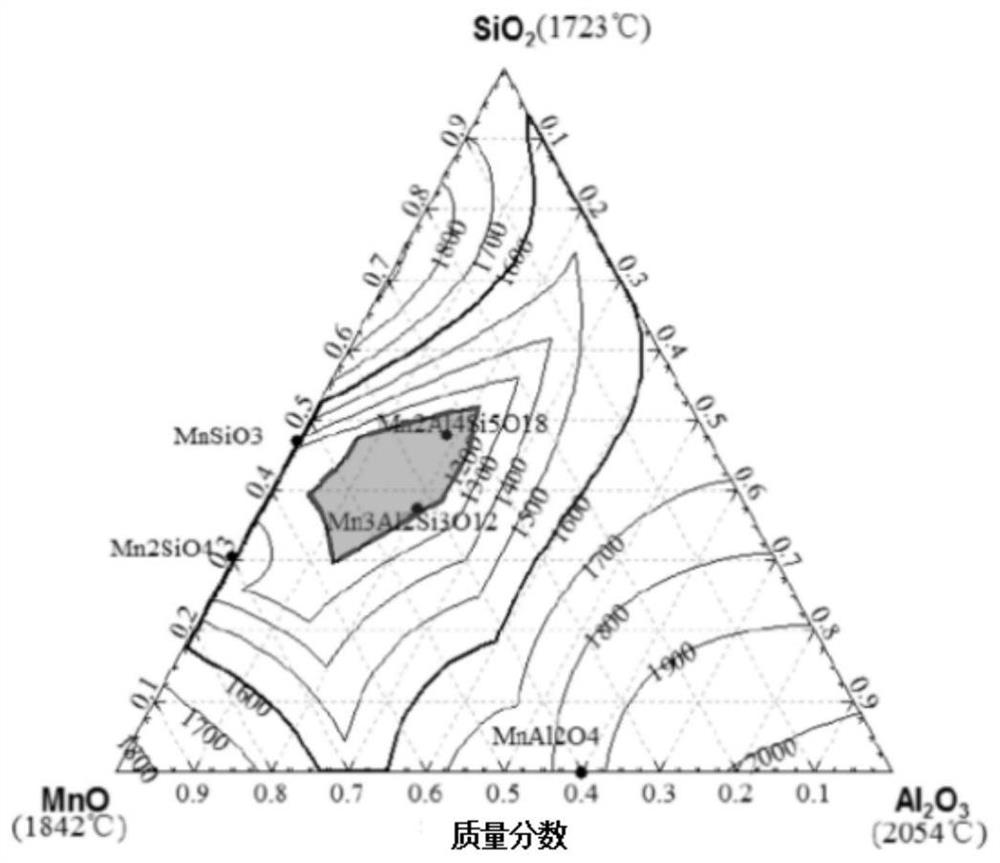

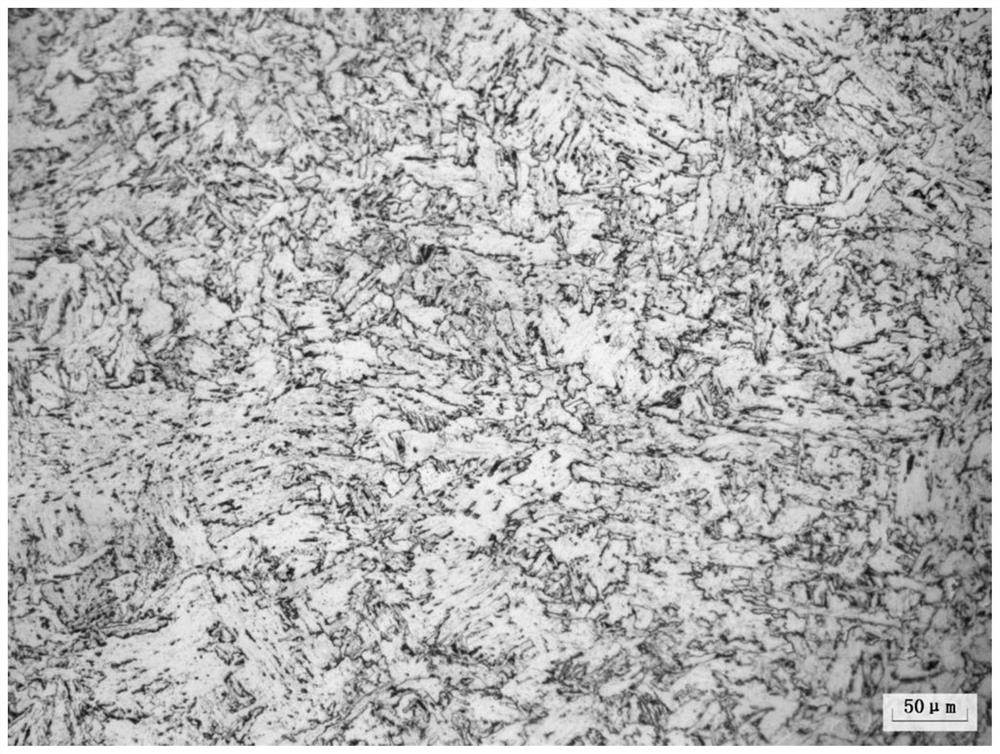

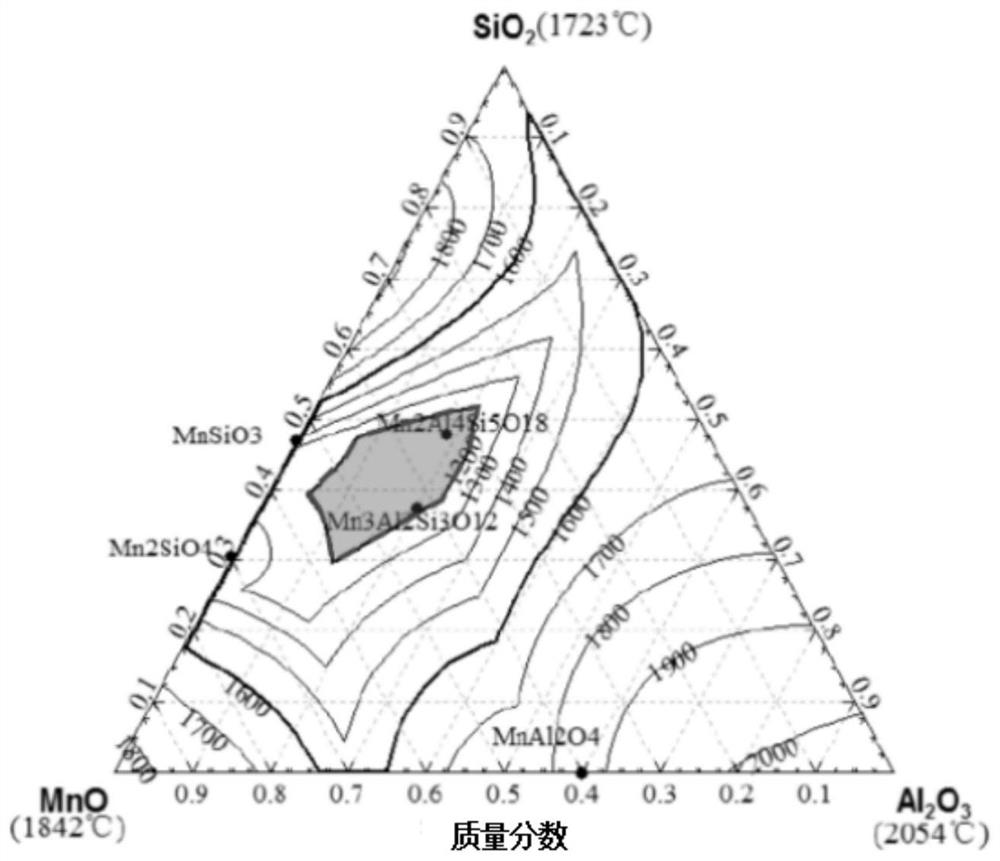

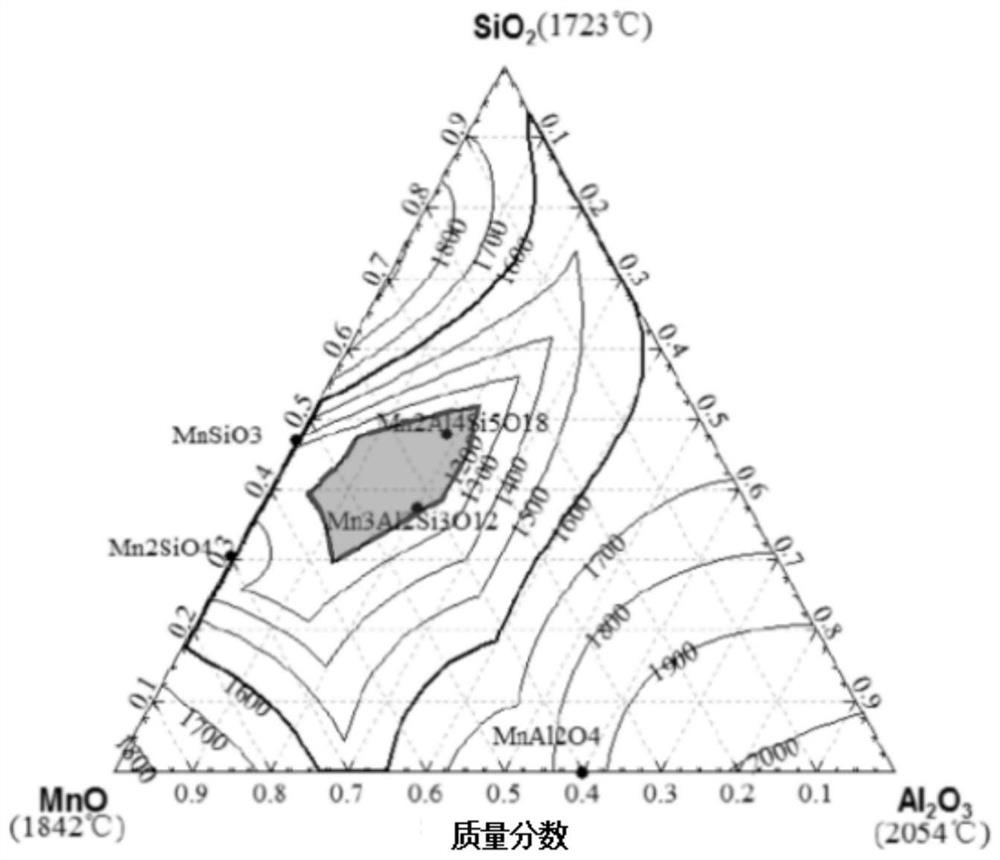

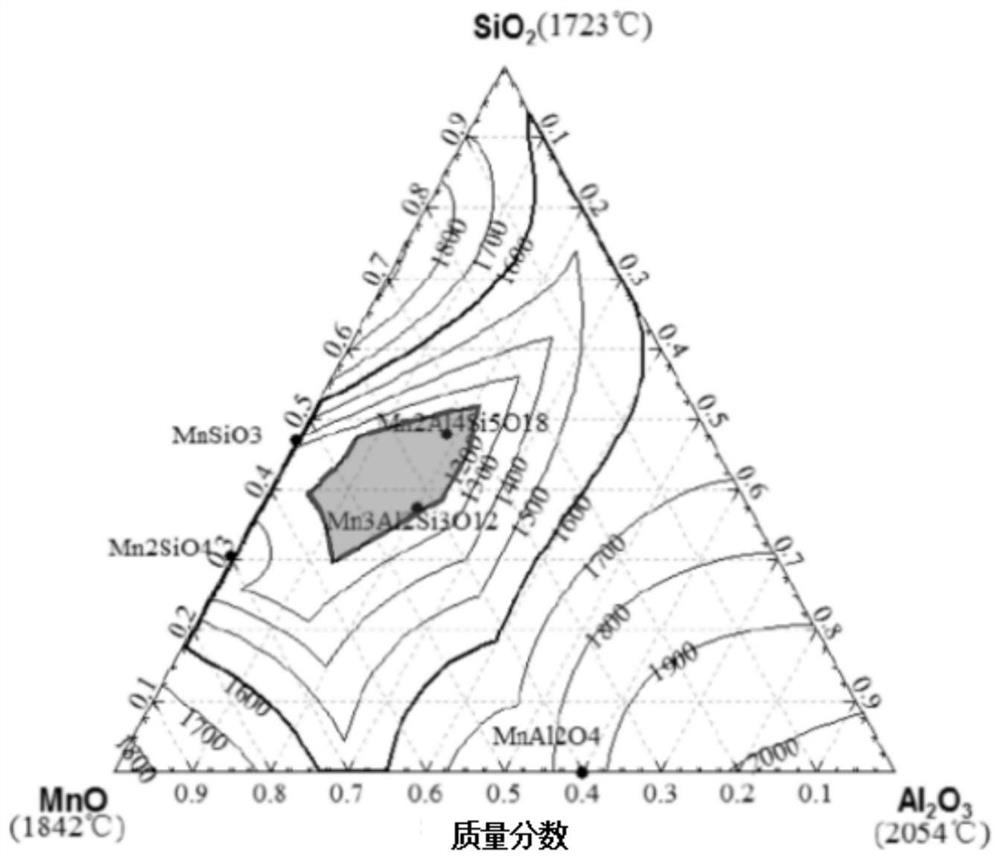

Martensitic steel strip and manufacturing method thereof

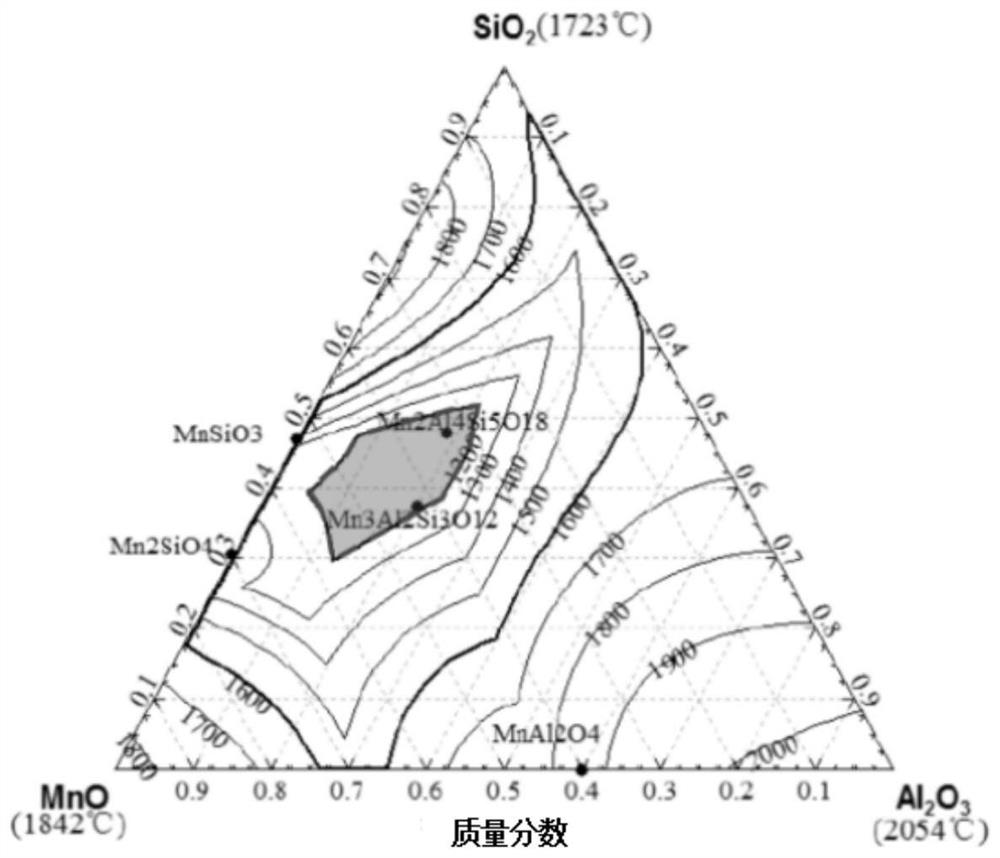

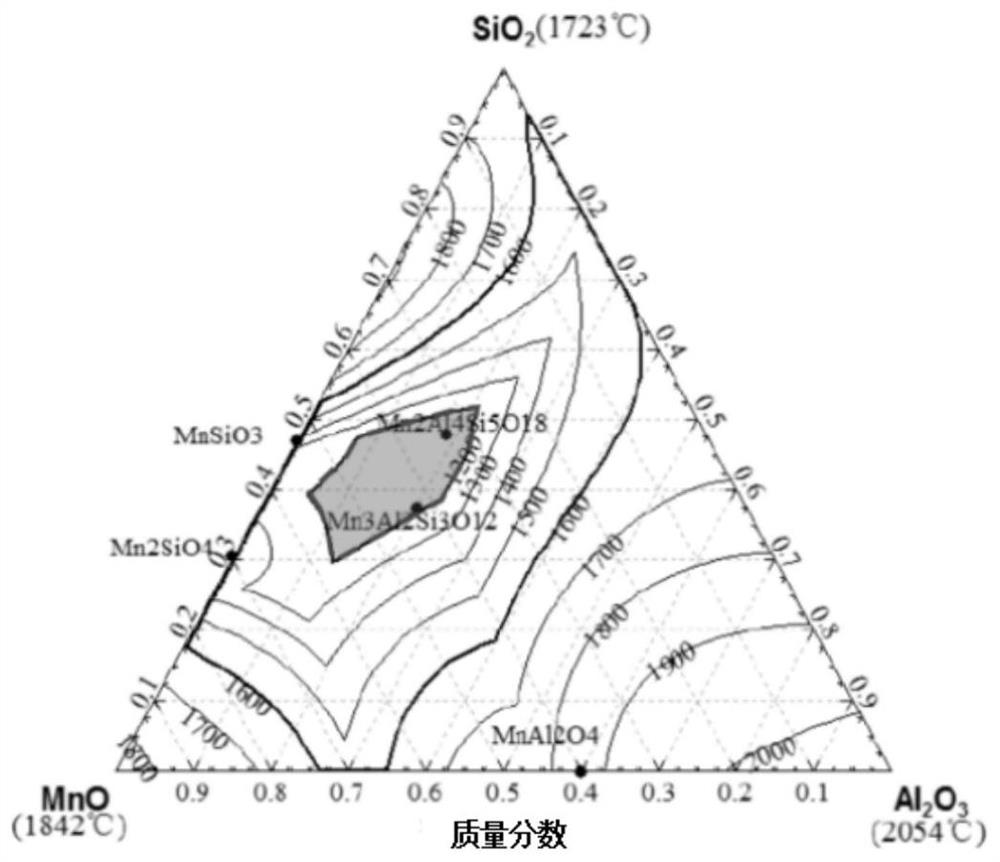

The invention discloses a martensitic steel strip and a manufacturing method thereof. The martensitic steel strip is prepared from the components in percentage by weight: 0.16-0.26% of C, 0.1-0.5% ofSi, 0.4-1.7% of Mn, less than or equal to 0.02% of P, less than or equal to 0.007% of S, 0.004-0.010% of N, less than 0.001% of Als, 0.001-0.006% of B, 0.007-0.020% of total oxygen [O]< T>, and the balance of Fe and inevitable impurities; the conditions that Mn / S is greater than 250, and one or two of 0.01-0.08% of Nb or 0.1-0.4% of Mo are included need to be met at the same time. Nb, Mo and B elements are selectively added; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process. According to the martensitic steel strip and the manufacturing method thereof, the yield strength of the martensitic steel strip is 700-1200 MPa, tensile strength is 1000-1800 MPa, elongation is 3-12%, the martensitic steel strip can be widely applied to the field of high-strength automobile steel, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

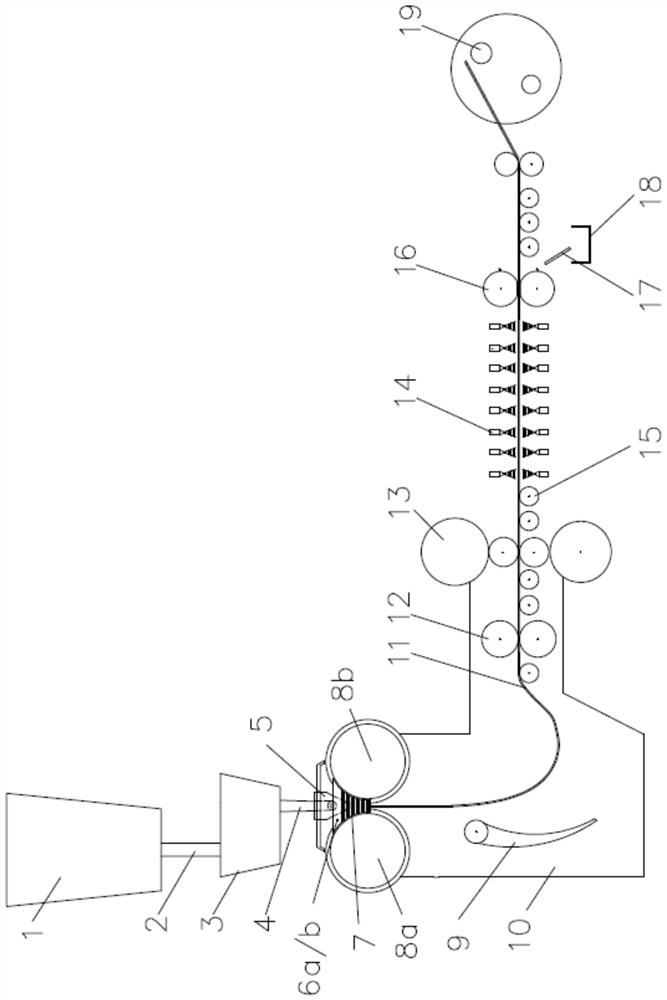

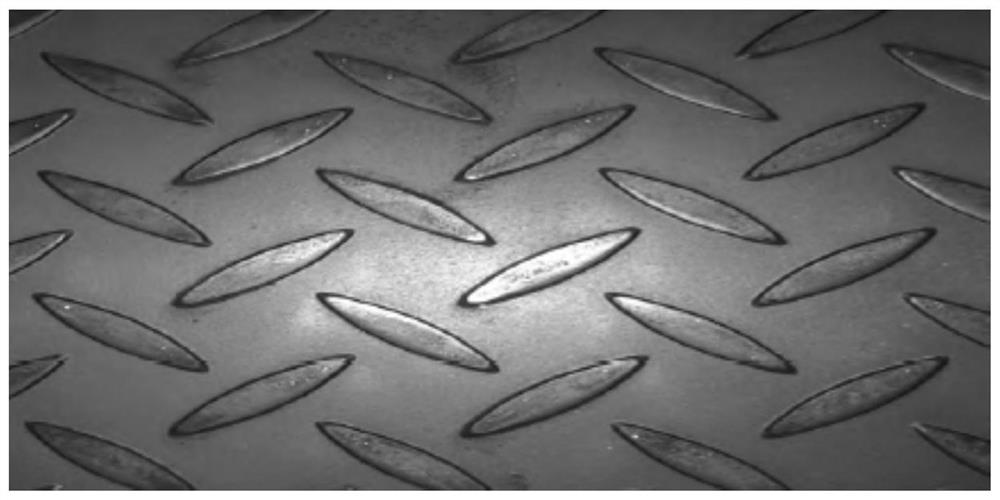

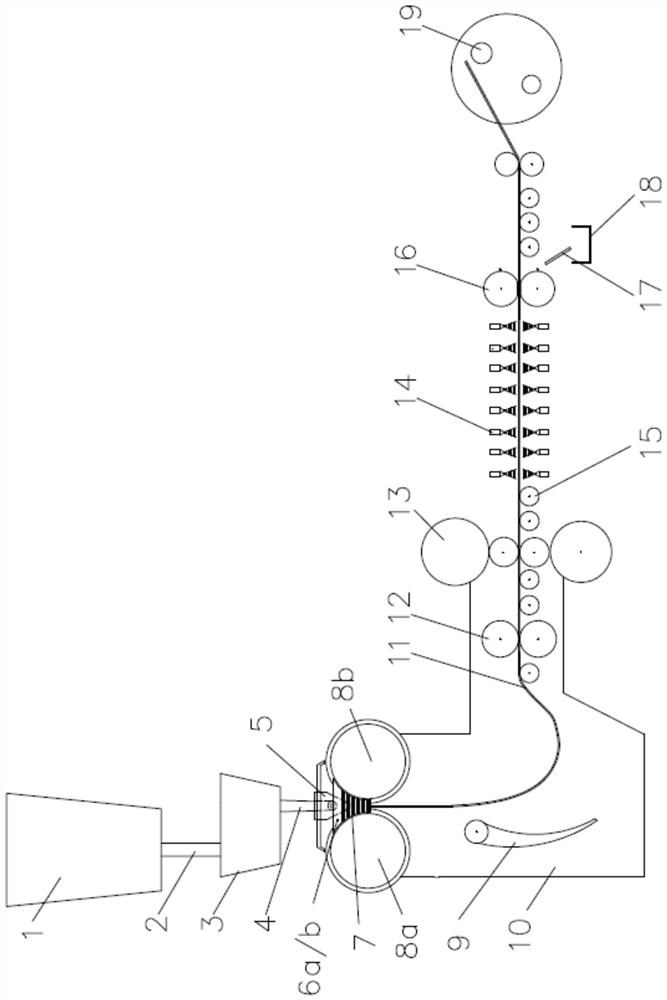

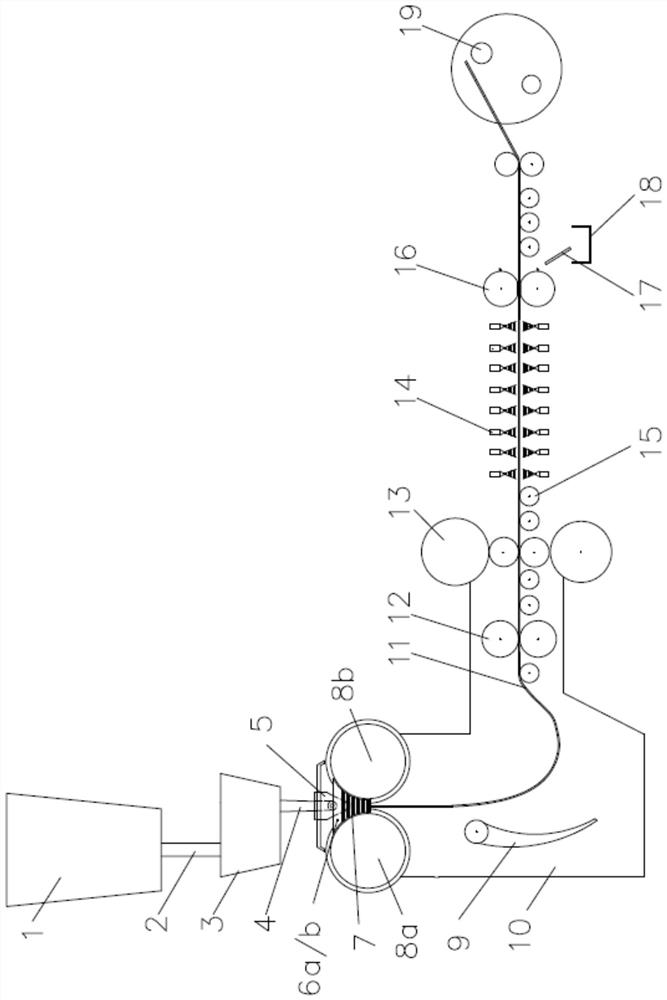

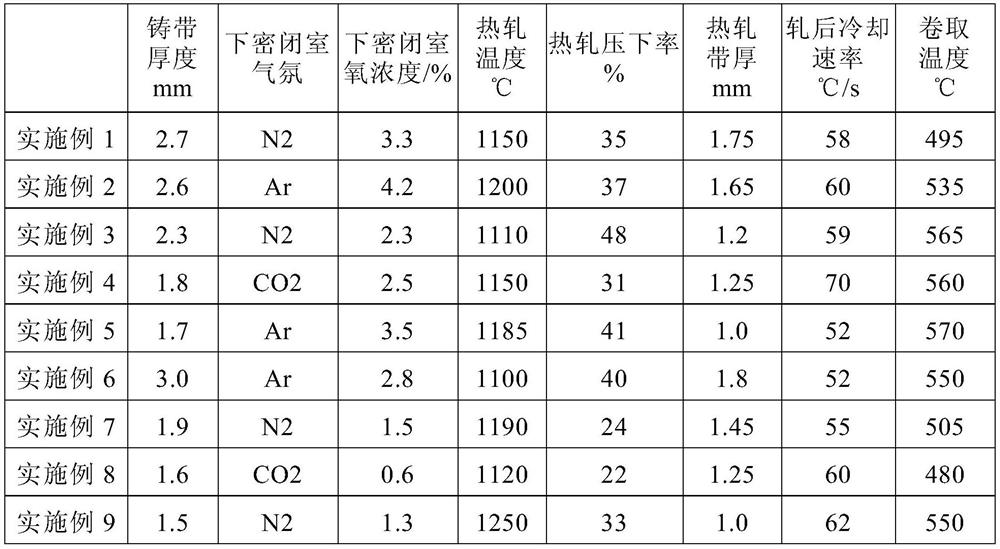

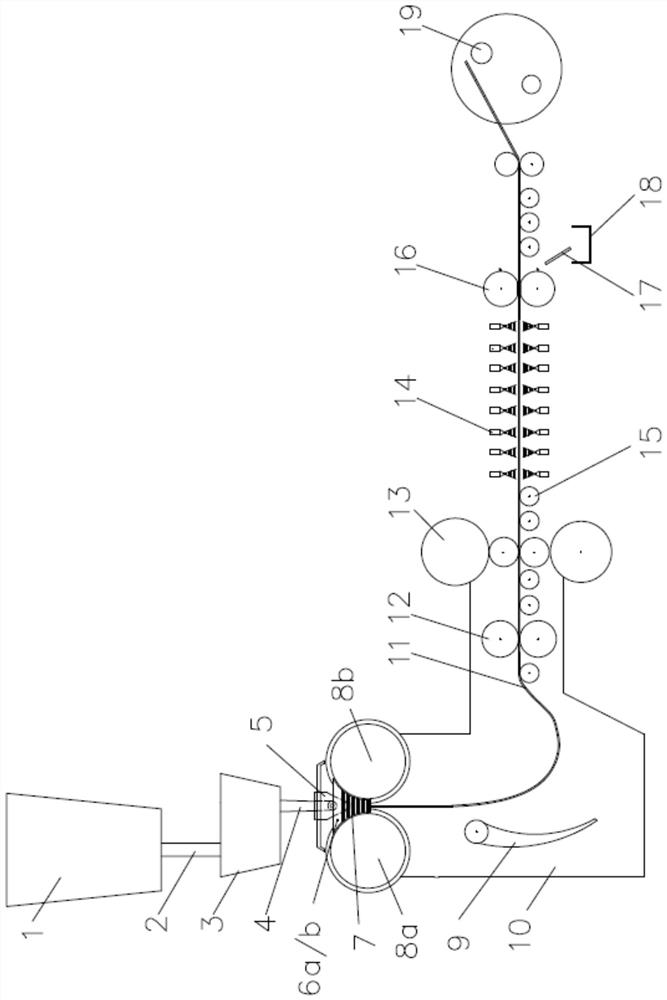

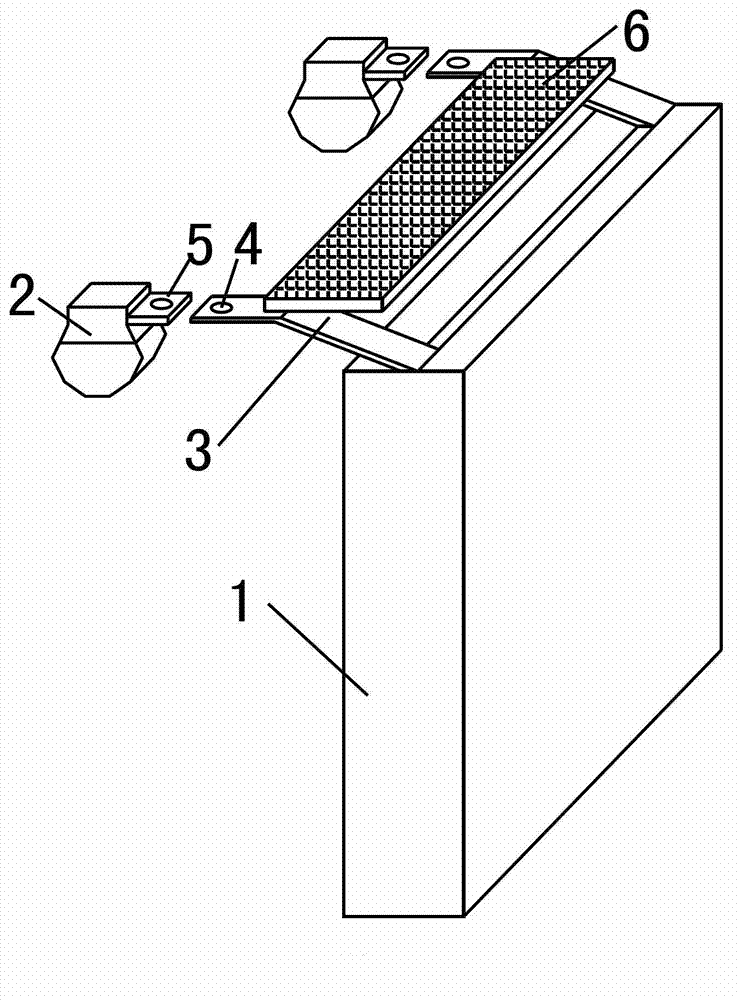

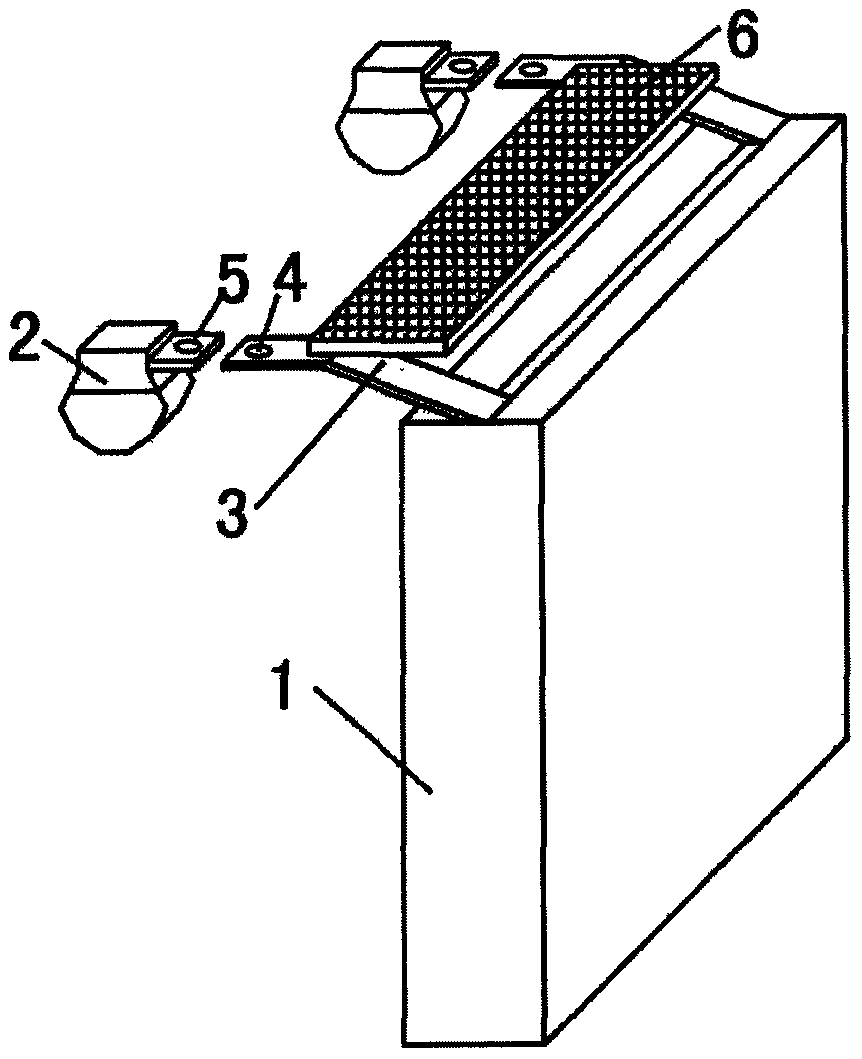

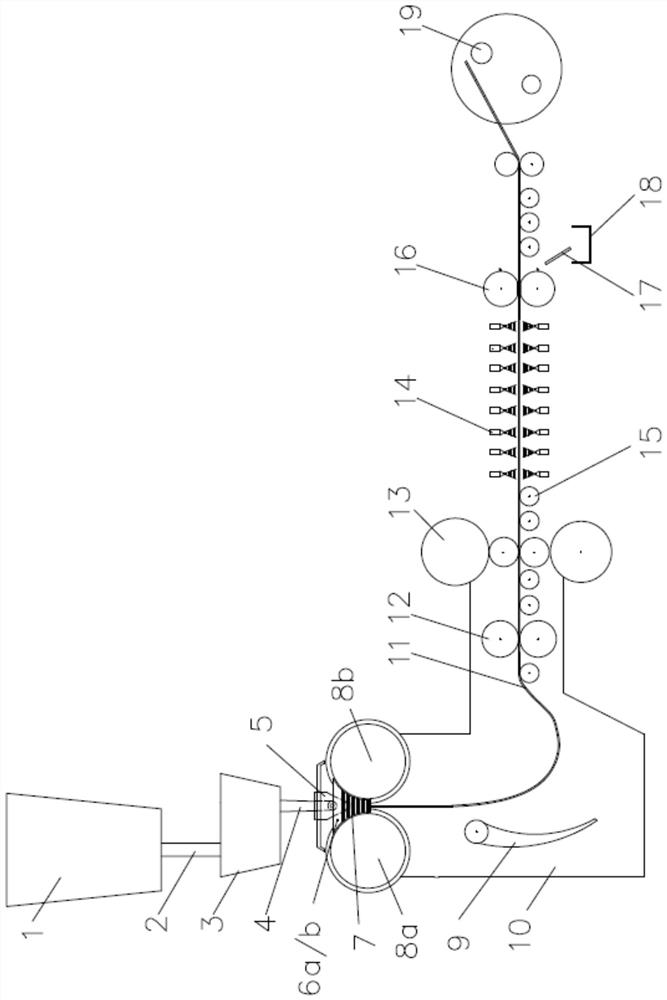

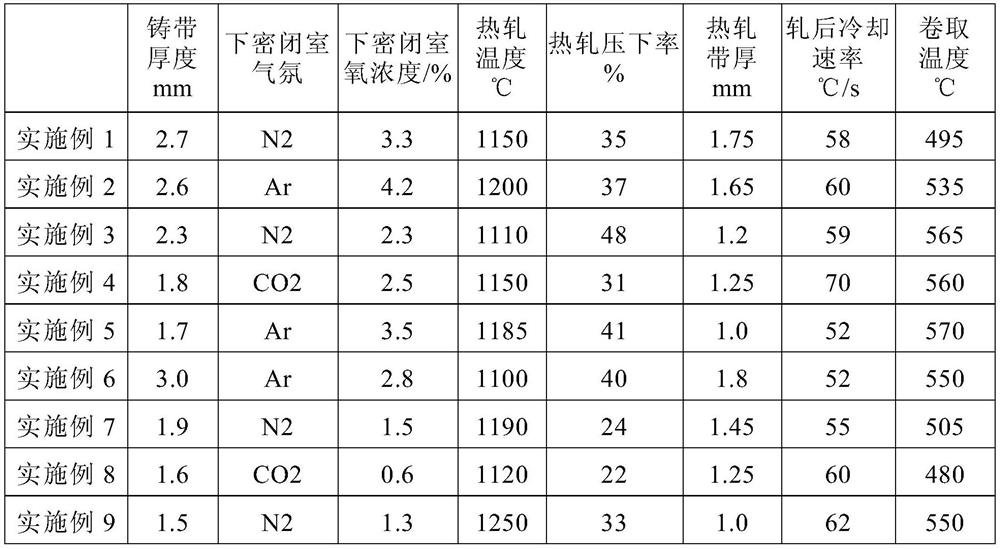

Method for producing thin-gauge riffled plate/strip through thin-strip continuous casting

The invention discloses a method for producing a thin-gauge riffled plate / strip through thin-strip continuous casting. According to the method, the alkalinity of slag, the types and melting points ofinclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in a smelting process; then a cast strip with a thickness of 1.5-3 mm is cast through twin-roll thin-strip continuous casting, and cast strip steel directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of a crystallization roller and enters an online rolling mill under the closed condition to be subjected to hot rolling; a rolled steel strip is cooled in a gas atomization cooling manner; and finally a steel coil is obtained through coiling. The steel coil can be directly used as a hot-rolled riffled plate / strip, and can also be used as a finished riffled plate / strip after being subjected to edge trimming and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

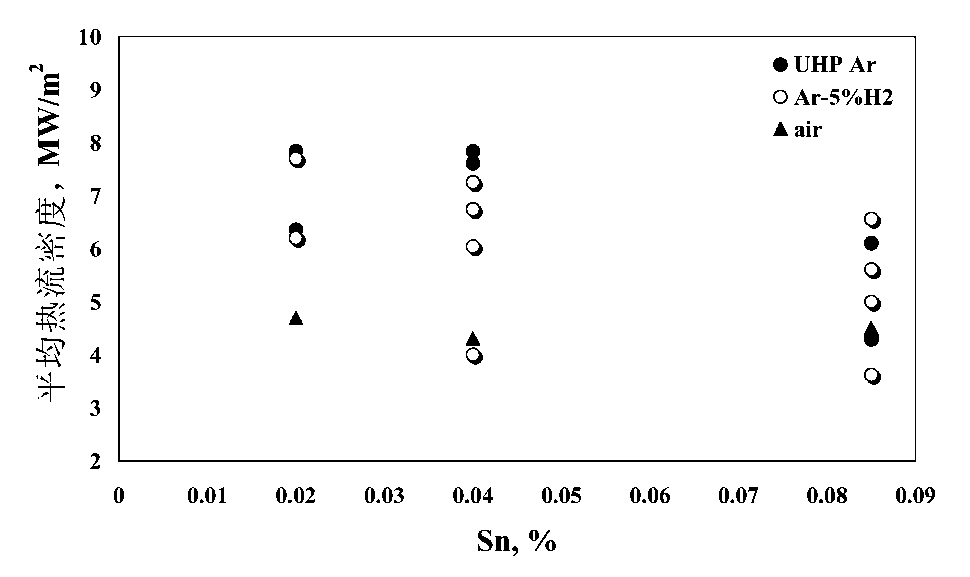

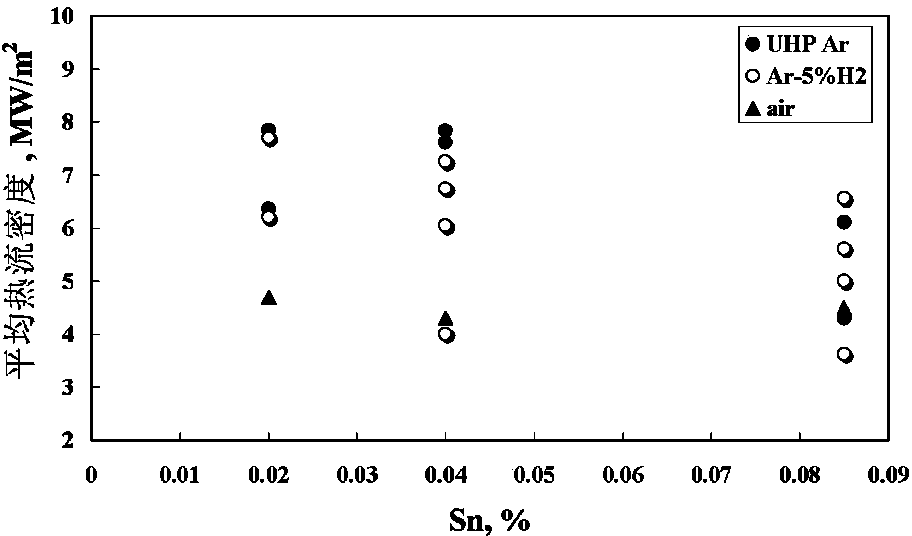

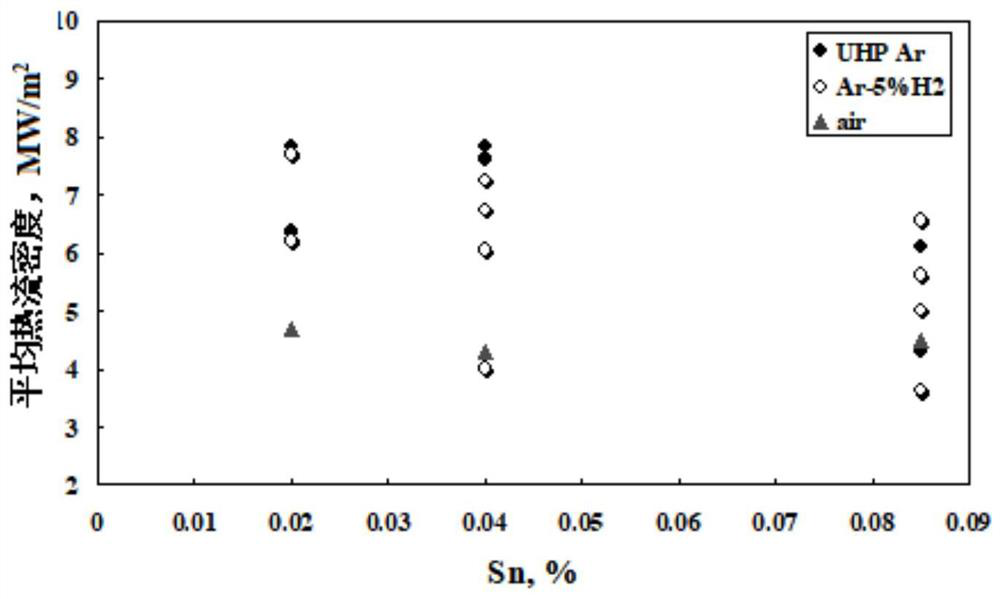

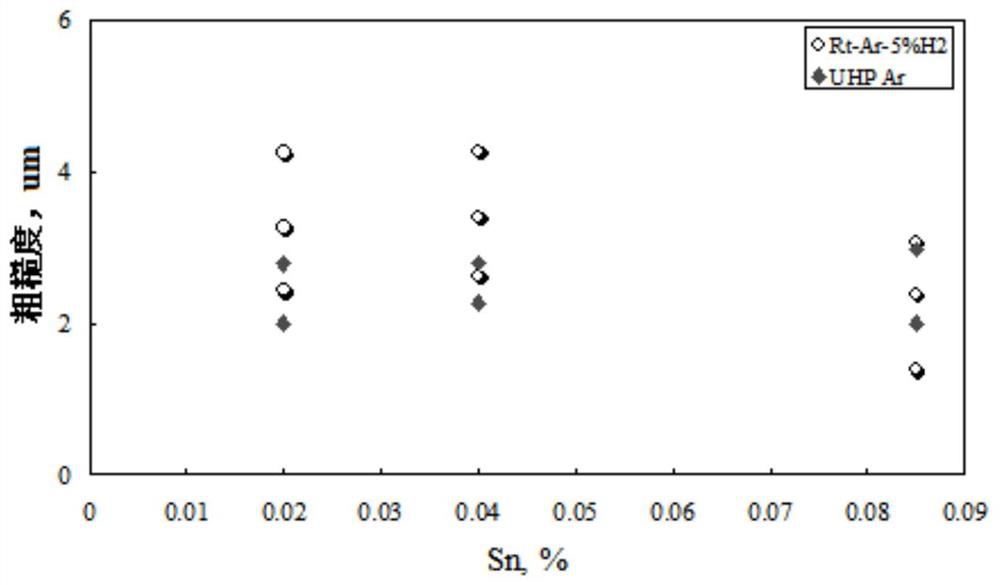

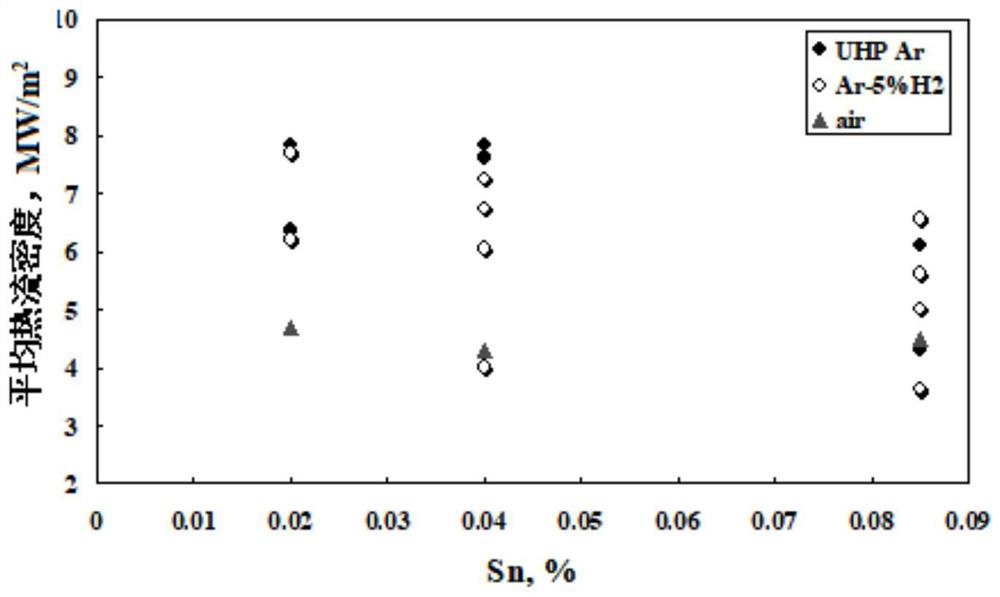

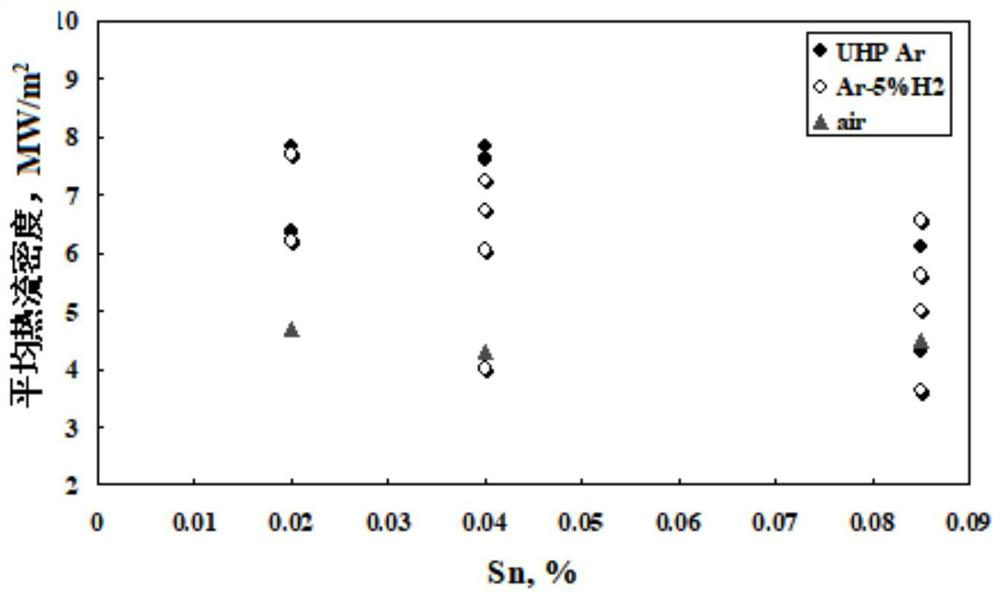

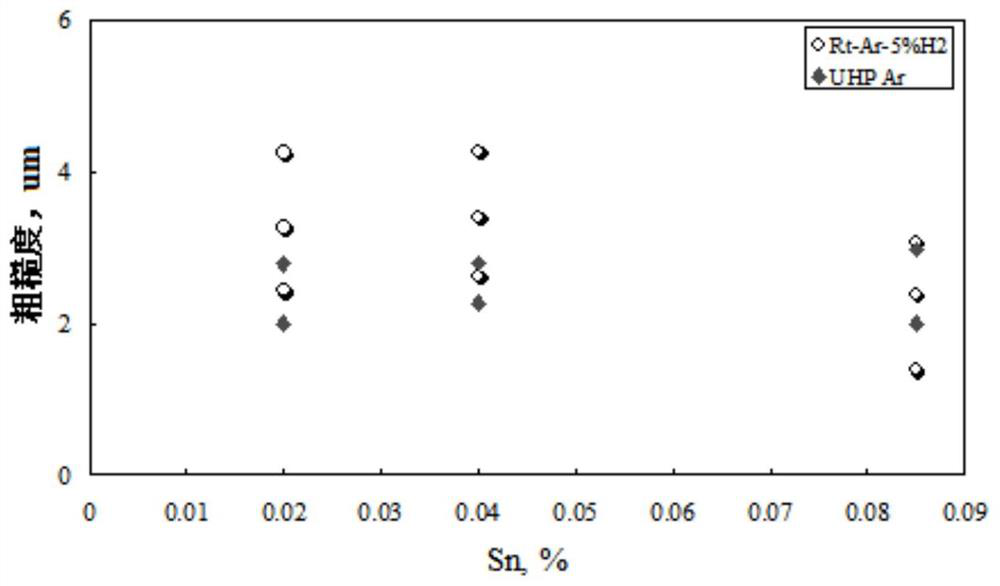

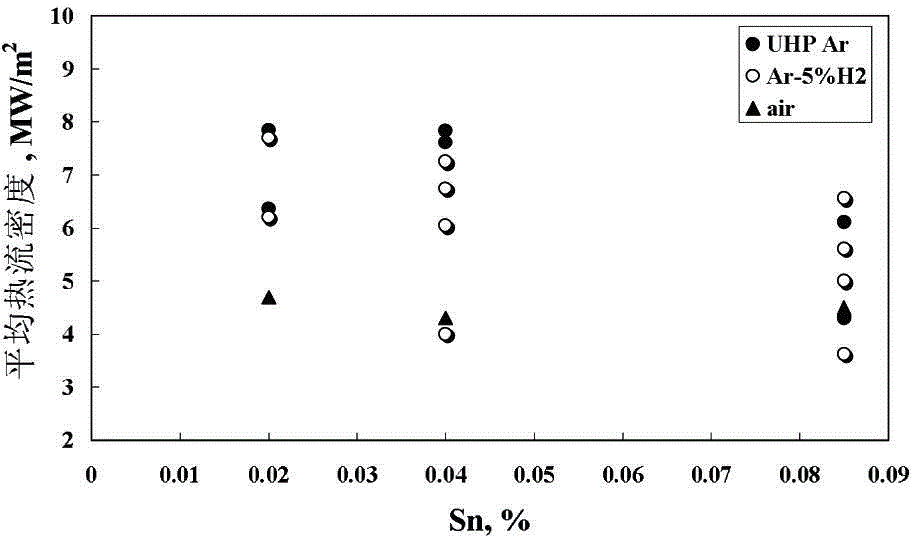

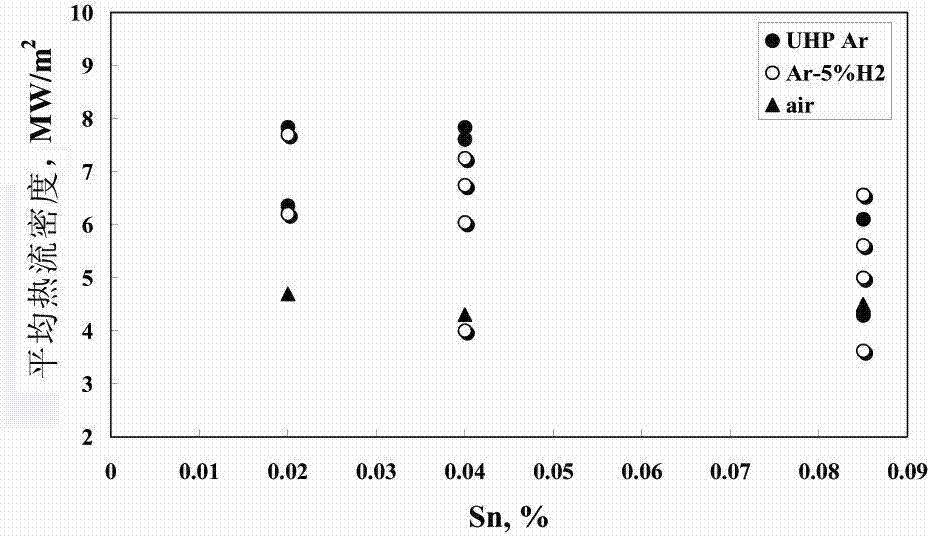

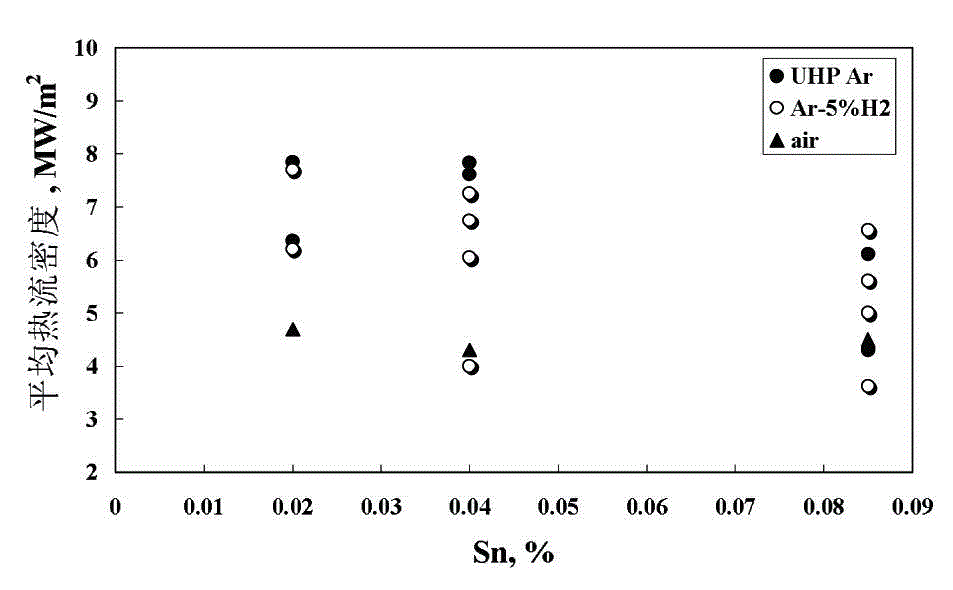

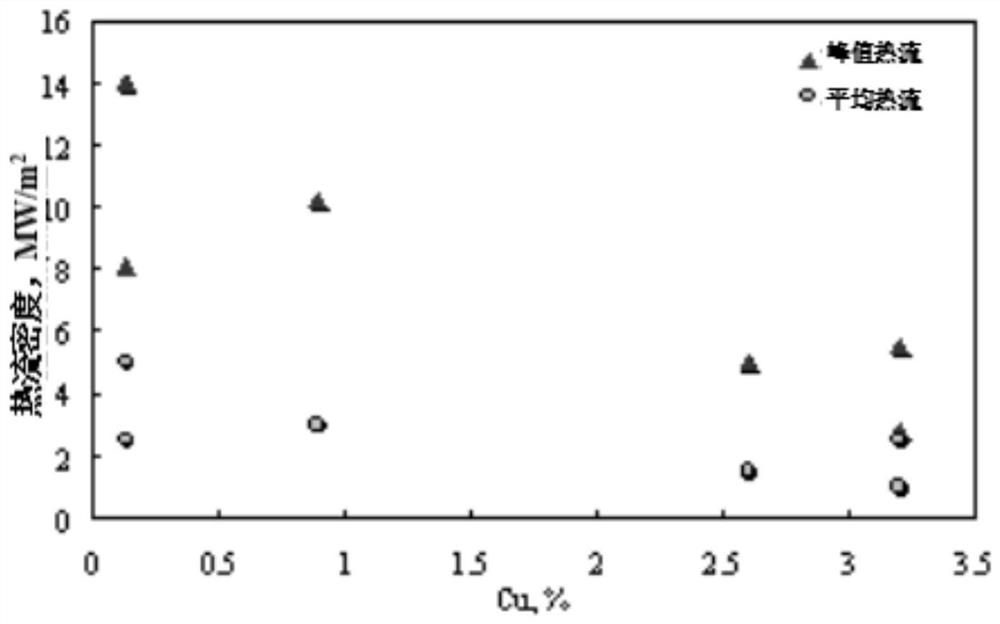

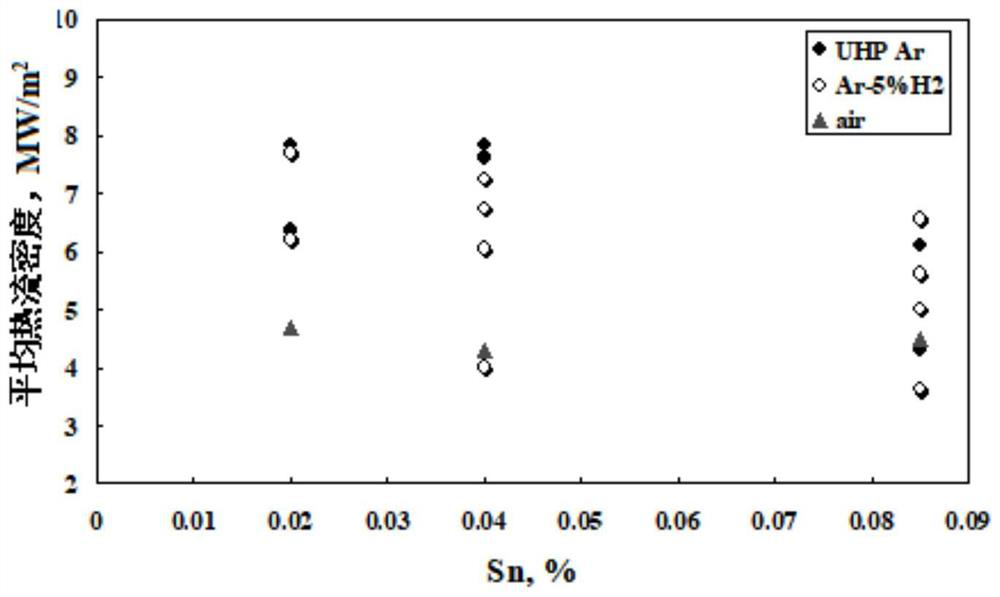

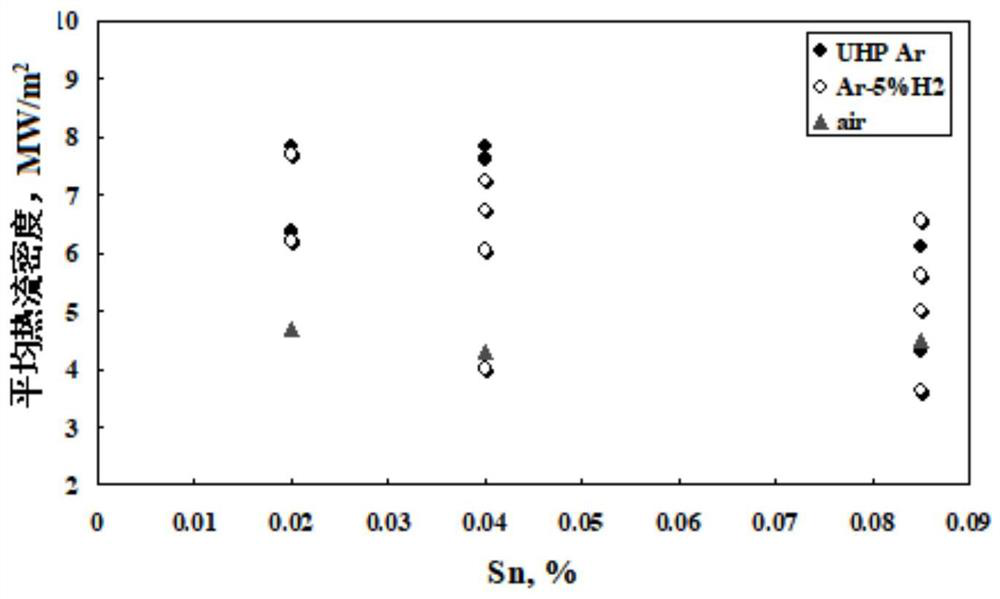

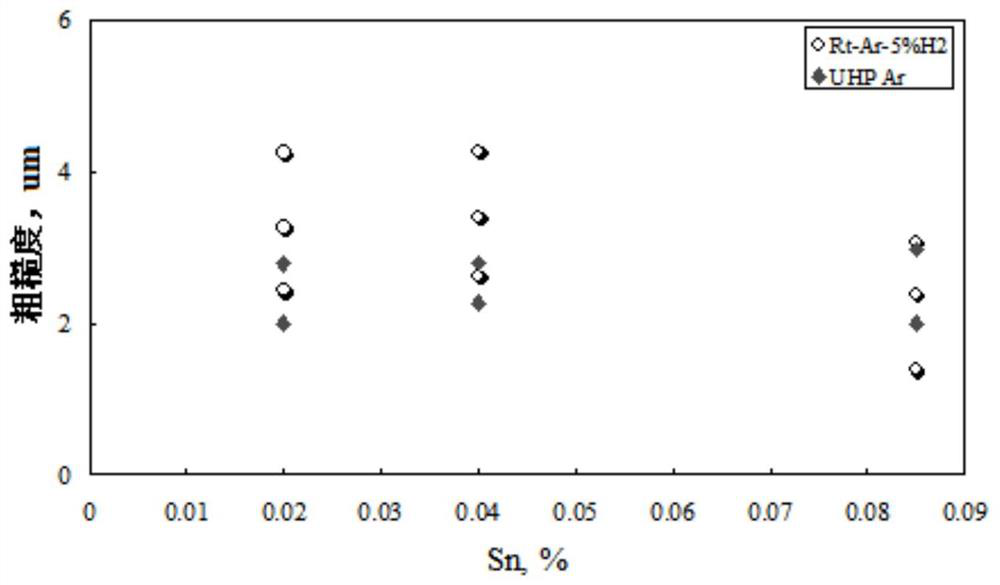

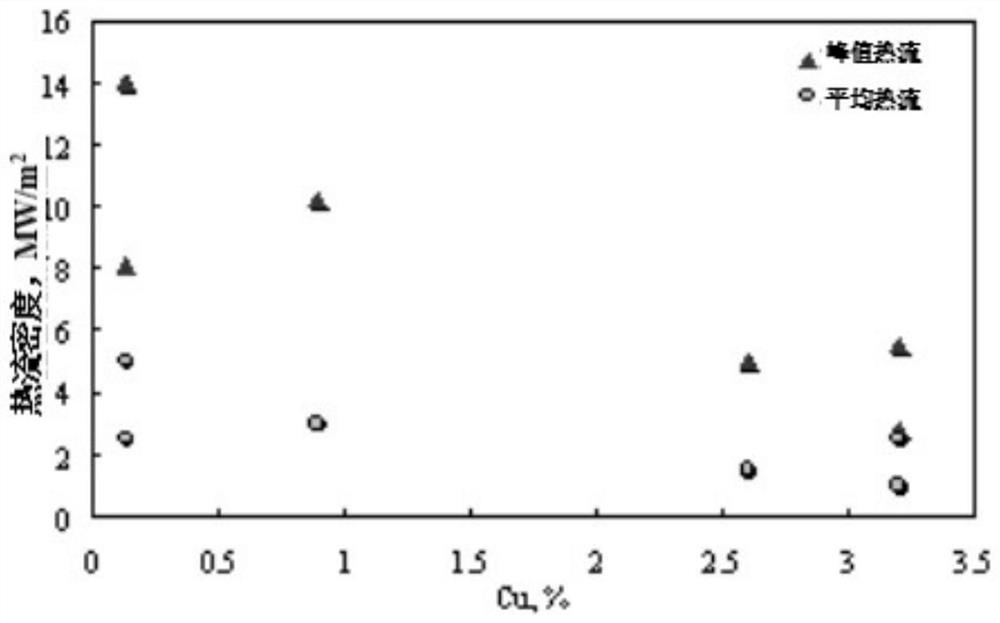

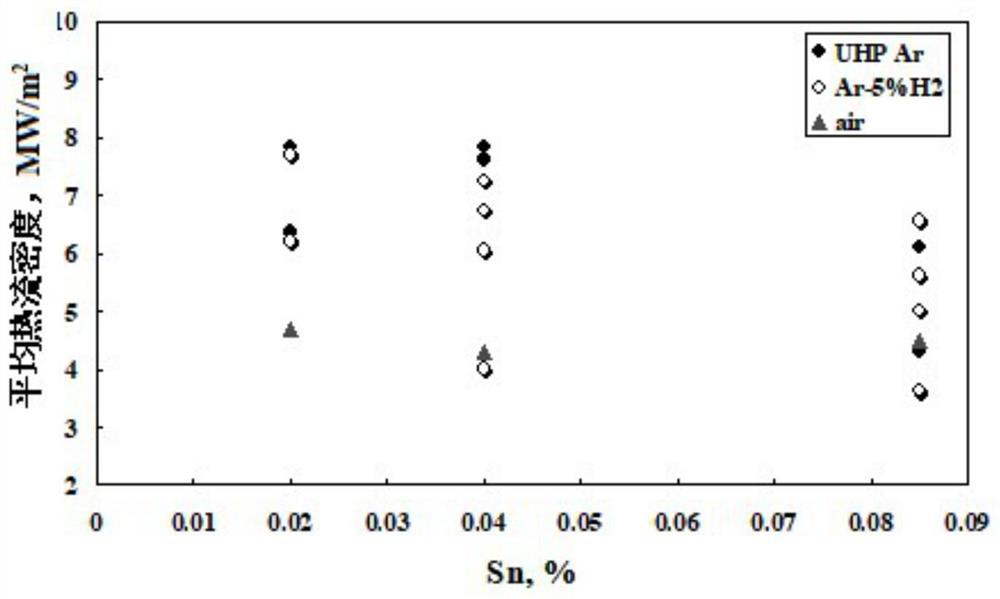

B-containing martensitic steel strip and manufacturing method thereof

The invention relates to a B-containing martensitic steel strip and a manufacturing method thereof. The B-containing martensitic steel strip comprises the following components in percentage by weight:0.16-0.26% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.007% of S, 0.004-0.010% of N, smaller than 0.001% of Als, 0.001-0.006% of B, 0.007-0.020% of total oxygen [O]T, the balance of Fe and inevitable impurities, one or two of 0.1-0.6% of Cu or 0.005-0.04% of Sn, one or two of 0.01-0.08% of Nb and 0.1-0.4% of Mo, and greater than 250 of Mn / S. According to the B-containing martensitic steel strip, residual Sn, Cu and other elements in scrap steel are used for smelting, and Nb / Mo and other microalloy elements and an element B are selectively added. According to the B-containing martensitic steel strip, the yield strength is 800-1200 MPa, the tensile strength is 1100-1900 MPa, the elongation is 3-12%, the martensitic steel strip can bewidely applied to the field of high-strength automotive steel, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-gauge riffled plate/strip and manufacturing method thereof

ActiveCN112522566AShort production processImprove efficiencyFurnace typesWork cooling devicesSmelting processMachine building

The invention discloses a thin-gauge riffled plate / strip and a manufacturing method thereof. Microalloy elements such as B are selectively added into steel; the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process; then, double-roller thin-strip continuous casting is carried out to cast strip steel with the thickness of 1.5-3 mm, and the strip steel directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of crystallization rollers and enters an online rolling mill under the closed condition to be subjected to hot rolling; and the rolled strip steel is cooled by adopting a gas atomization cooling mode,and the gas atomization cooling mode can effectively reduce the thickness of surface scale of the strip steel, improve the temperature uniformity of the strip steel and improve the surface quality ofthe strip steel. A finally produced steel coil can be directly used as a hot-rolled riffled plate / strip, can also be used as a finished riffled plate / strip after being trimmed and leveled, and can bewidely applied to the fields of buildings, machine manufacturing, automobiles, bridges, traffic, shipbuilding and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-gauge martensitic steel strip and manufacturing method thereof

ActiveCN112522633AShort production processImprove efficiencyHeat treatment process controlSmelting processMolten steel

The invention discloses a thin-gauge martensitic steel strip and a manufacturing method thereof. The thin-gauge martensitic steel strip is prepared from the following components in percentage by weight: 0.16-0.26% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, less than or equal to 0.02% of P, less than or equal to 0.007% of S, 0.004-0.010% of N, less than 0.001% of Als, 0.007-0.020% of total oxygen [O]<T>, and the balance of Fe and other inevitable impurities. Meanwhile, the thin-gauge martensitic steel strip meets the following requirements: the thin-gauge martensitic steel strip contains one or twoof 0.1-0.6% of Cu or 0.005-0.04% of Sn; the thin-gauge martensitic steel strip contains one or two of 0.01-0.08% of Nb and 0.1-0.4% of Mo; and Mn / S is greater than 250. The manufacturing method comprises the following steps: smelting molten steel by using residual Sn, Cu and other elements in scrap steel, and selectively adding Nb / Mo and other microalloy elements into the steel; in the smelting process, controlling the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in the molten steel and the content of acid-soluble aluminum Als; and thencarrying out double-roller strip continuous casting to cast a cast strip, and carrying out online hot rolling and gas atomization rapid cooling to obtain the thin-gauge martensitic steel strip.

Owner:BAOSHAN IRON & STEEL CO LTD

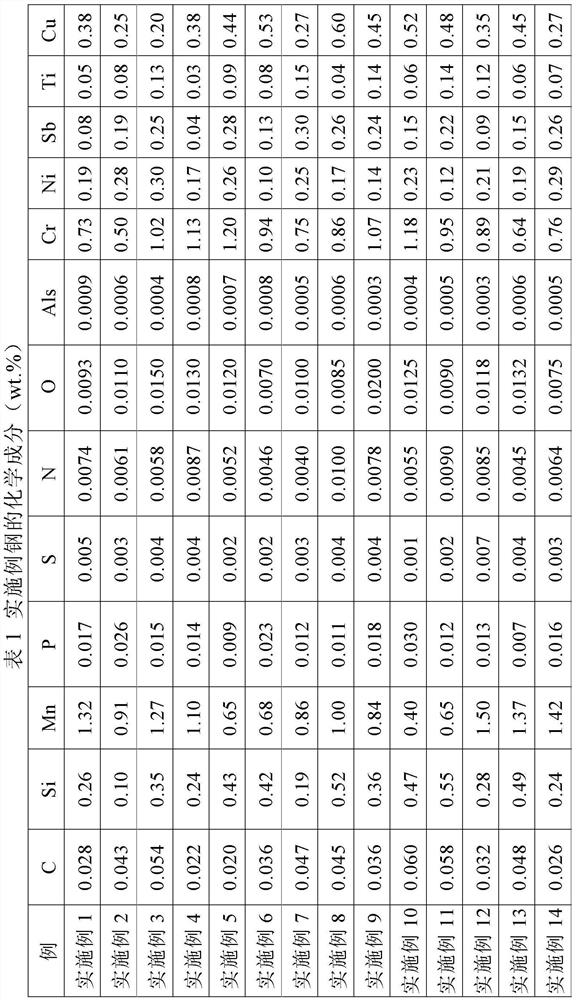

High-strength fire-resistant and weather-resistant steel plate/strip and production method thereof

The invention relates to a high-strength fire-resistant and weather-resistant steel plate / strip and a production method thereof. The steel plate / strip comprises the following chemical components in percent by weight: 0.02-0.06% of C, 0.1-0.55% of Si, 0.4-1.7% of Mn, less than or equal to 0.03% of P, less than or equal to 0.007% of S, 0.30-0.80% of Cr, 0.10-0.60% of Cu, 0.20-0.60% of Mo, 0.01-0.08%of Nb, 0.004-0.010% of N, less than or equal to 0.001% of Als, 0.007-0.020% of total oxygen [O]T and the balance Fe and inevitable impurities, wherein Mn / S is greater than 250; and Pcm is smaller than or equal to 0.27%. The production method comprises the following steps of: selectively adding micro-alloy elements such as Mo / Nb / Cr into steel, and controlling the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als; then casting a cast strip through double-roller thin strip continuouscasting, and then feeding the cast strip into an on-line rolling mill for hot rolling; and after rolling, cooling the strip steel in a gas atomization cooling mode, and finally coiling the strip steeldirectly into a steel coil.

Owner:BAOSHAN IRON & STEEL CO LTD

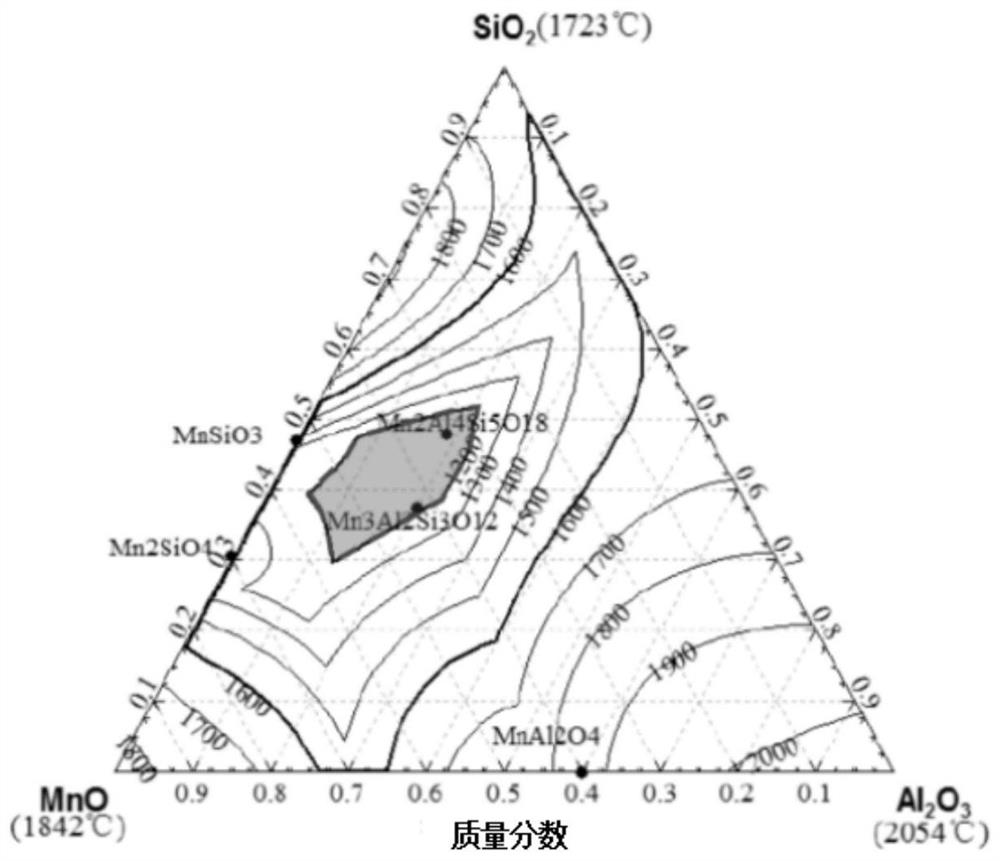

Boron-containing high-reaming steel and production method thereof

The invention discloses boron-containing high-reaming steel and a production method thereof. The steel comprises the following chemical components of, in percentage by weight, 0.01%-0.05% of C, 0.2%-0.6% of Si, 0.8%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001% of Als, less than or equal to 0.0050% of Ca, 0.001%-0.006% of B, 0.007%-0.020% of total oxygen [O]T, Mn / S is large than 250 and the balance Fe and inevitable impurities. According to the steel, microalloy elements such as B are selectively added intothe steel; in a smelting process, the alkalinity of slag, a type and a melting point of an inclusion in steel, a content of free oxygen in molten steel and a content of acid-soluble aluminum Als are controlled; then, double-roller thin strip continuous casting is carried out to cast a cast strip with a thickness of 1.5-3 mm, and the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under the closed condition; and after rolling, strip steel is cooled in a gas atomization cooling mode, and a produced steel coil canbe directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot-rolled steel plate/strip for sulfuric acid dew point corrosion resistance and manufacturing method thereof

ActiveCN112522599AShort production processImprove efficiencyProcess efficiency improvementAir preheaterPetrochemical

The invention discloses a hot-rolled steel plate / strip for sulfuric acid dew point corrosion resistance and a manufacturing method thereof. Residual Sn, Cu and other elements in steel scrap are fullyutilized for molten steel smelting, and Cr, Ti, Sb and other microalloy elements are selectively added; in a smelting process, the alkalinity of slag, a type and a melting point of inclusions in steel, a content of free oxygen in molten steel and a content of acid-soluble aluminum Als are controlled; and then a cast strip is cast by adopting double-roller thin strip continuous casting, directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged from a crystallization roller, and enters an online rolling mill for hot rolling under a closed condition, rolled strip steel is cooled by adopting a gas atomization cooling mode, and finally the strip steel is coiled. The steel can be widely applied to the field of products with sulfuric acid dew point corrosion resistance requirements in use environments such as tobacco baking equipment, air preheater heat exchange elements, conveying pipelines, flues, chimney manufacturing structural parts, boiler preheatersand economizer equipment in industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Fire-resistant and weather-resistant steel plate/strip and production method thereof

ActiveCN112522638AIncrease production costShort production processHeat treatment process controlWeather resistanceStrip steel

The invention discloses a fire-resistant and weather-resistant steel plate / strip and a production method thereof. The fire-resistant and weather-resistant steel plate / strip comprises, by weight, 0.02-0.06% of C, 0.1-0.55% of Si, 0.4-1.7% of Mn, less than or equal to 0.03% of P, less than or equal to 0.007% of S, 0.30-0.80% of Cr, 0.10-0.60% of Cu, 0.20-0.60% of Mo, 0.004-0.010% of N, less than 0.001% of Als, 0.007-0.020% of total oxygen [O]T and the balance Fe and other inevitable impurities; and besides, the Mn / S ratio is greater than 250, and the Pcm is less than or equal to 0.27%. The produced fire-resistant and weather-resistant steel plate / strip can ensure that the steel can keep a high strength level at a high temperature, and also can reduce the mass of a building, improve the safety of the building and reduce the construction cost; and meanwhile, by utilizing the technological characteristics of thin-strip continuous casting, a fine grain layer with a certain thickness can be naturally formed on the strip steel surface on the basis of the fire resistance of the produced fire-resistant and weather-resistant steel plate / strip, and therefore the product has weather resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of thin hot-rolled steel plate/strip for sulfuric acid dew point corrosion resistance

ActiveCN112522585AShort production processImprove efficiencyProcess efficiency improvementAir preheaterPetrochemical

The invention relates to a thin hot-rolled steel plate / strip for sulfuric acid dew point corrosion resistance and a production method thereof. Residual Sn, Cu and other elements in scrap steel are used fully to smelt molten steel, and Cr, Ti, Sb and other microalloy elements and B element are selectively added into the steel. The production method comprises the steps of: in a smelting process, controlling the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als; and then casting a cast strip through double-roller thin strip continuous casting, feeding the cast strip into an on-line rolling mill for hot rolling under a closed condition, cooling strip steel in a gas atomization cooling mode after rolling, and finally conducting coiling. The steel disclosed by the invention can be widely applied to the field of products with sulfuric acid dew point corrosion resistance requirements inuse environments such as tobacco baking equipment, air preheater heat exchange elements, conveying pipelines, flues, chimney manufacturing structural parts, boiler preheaters and economizer equipmentin industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-strip continuously cast high-reaming steel and production method thereof

The invention discloses thin-strip continuously cast high-reaming steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.01-0.05% of C,0.2-0.6% of Si, 0.8-1.5% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.008% of N, smaller than 0.001% of Als, smaller than or equal to 0.0050% of Ca, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]T and the balance of Fe and other inevitable impurities. In the smelting process, the alkalinity of slag, the types and meltingpoints of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled; then a cast strip with a thickness of 1.5-3 mm is cast through twin-roll thin-strip continuous casting, and the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of a crystallization roller and enters an online rolling mill under the closed condition to be subjected to hot rolling; strip steel is cooled in a gas atomization cooling manner after being rolled; and finally the produced steel coil can be directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

Boron-containing high-strength high-reaming steel and manufacturing method thereof

The invention relates to boron-containing high-strength high-reaming steel and a manufacturing method thereof. The boron-containing high-strength high-reaming steel is prepared from the chemical components in percentage by weight: 0.01-0.05% of C, 0.2-0.6% of Si, 0.8-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001%of Als, less than or equal to 0.0050% of Ca, 0.001-0.006% of B, 0.01-0.08% of Nb, 0.007%-0.020% of total oxygen [O]<T>, and the balance of Fe and other inevitable impurities. Nb, B and other microalloy elements are selectively added into the steel; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-solublealuminum Als are controlled in the smelting process; then a cast strip is casted through double-roller thin strip continuous casting, directly enters a lower closed chamber with a non-oxidizing atmosphere, and enters an online rolling mill for hot rolling under a closed condition; rolled strip steel is cooled in a gas atomization cooling mode, and a produced steel coil can be directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

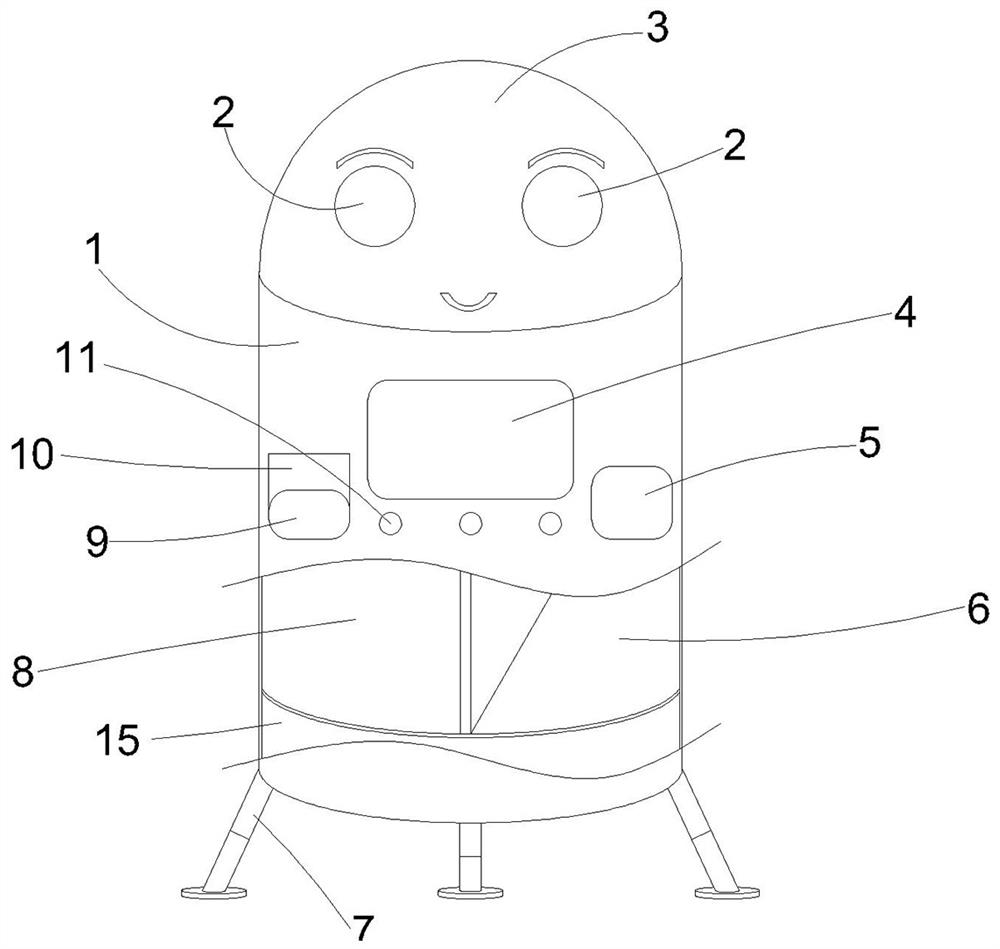

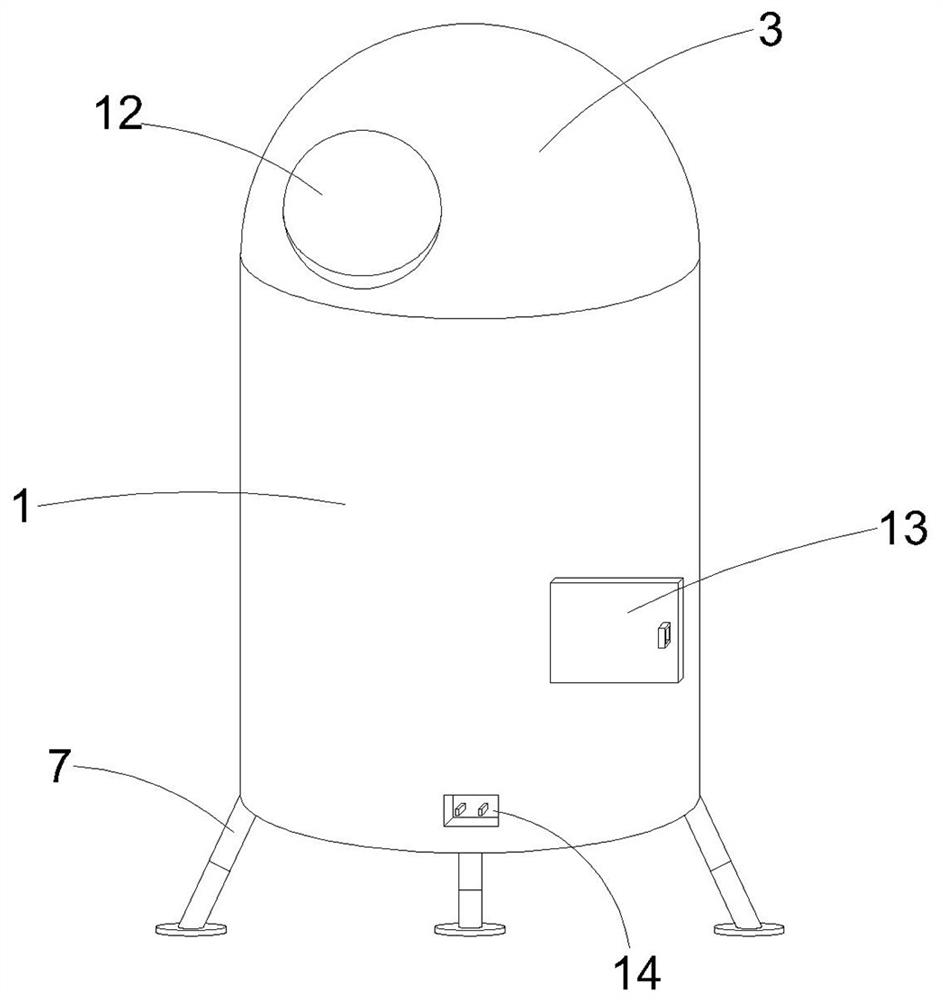

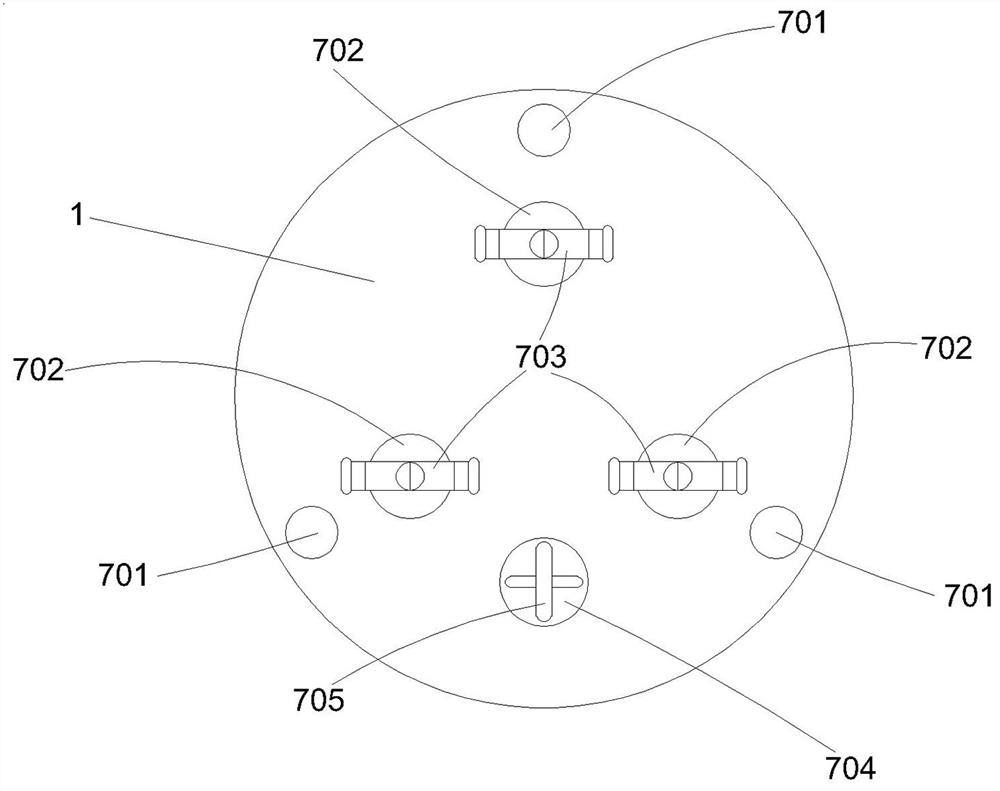

Intelligent robot for stoma patients

ActiveCN113059580ARealize the purpose of adjustmentEasy to rotate connectionManipulatorNursing accommodationRechargeable cellRechargeable battery pack

The invention belongs to the technical field of advanced manufacturing and automation, and particularly discloses an intelligent robot for stoma patients. The intelligent robot comprises a robot shell, a movement mechanism is arranged at the bottom end of the robot shell, a collection cavity, a supply cavity and a control mechanism are arranged in the robot shell, an ostomy bag collection mechanism is arranged in the collection cavity, and an ostomy bag supply mechanism is arranged in the supply cavity. The control mechanism comprises a panoramic camera, a recognition camera, a laser radar, a distance sensor, a control processor arranged in the robot shell and a rechargeable battery pack electrically connected with the control processor, wherein the panoramic camera, the recognition camera, the laser radar and the distance sensor are arranged at the top end of the robot shell, a timing module is arranged on a controller, and the control processor is electrically connected with a touch display screen and a sound alarm which are arranged on the robot shell. A control button electrically connected with the control processor is arranged on the robot shell.

Owner:HENAN CANCER HOSPITAL

Method for producing hot-rolled steel plate/strip with sulfuric acid dew point corrosion resistance through thin-strip continuous casting

ActiveCN112522643AShort production processImprove efficiencyHeat treatment process controlSmelting processClosed chamber

Owner:BAOSHAN IRON & STEEL CO LTD

A method for manufacturing high-strength thin strip steel for cold forming

ActiveCN103667895BTo achieve the purpose of supplyCost-effectiveMetal rolling arrangementsBoron nitrideYield ratio

The invention relates to high-strength thin strip steel for cold forming and a manufacturing method thereof. The manufacturing method comprises the following steps: performing uniform enhanced cooling on a cast strip by adopting a high-pressure dry ice spraying way after the cast strip is discharged from a crystallization roller, thus rapidly cooling the cast strip to below 1280 DEG C, wherein the cooling rate is 200-300 DEG C / s, and by adopting the cooling way of the strip steel after boron treatment, the precipitation of coarse BN (boron nitride) can be promoted, the appearance of low-melting point phase B2O3 and the precipitation of fine AlN can be prevented and the purposes of uniformizing austenite grains and reducing yield ratio are achieved; then performing austenite online recrystallization rolling; cooling the strip steel after hot rolling by atomization cooling, wherein the cooling rate of atomization cooling is 10-70 DEG C / s; coiling at the temperature of 650-750 DEG C. Through the manufacturing method provided by the invention, the high-strength thin strip steel for cold forming of an automobile, which has relatively low yield ratio and excellent stamping performance, can be obtained. The high-strength hot-rolled thin strip steel for cold forming, which is produced by the method, can be directly used for replacing cold-rolled steel with the hot-rolled steel, cancel a cold rolling process step and greatly reduce production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength thin band steel for cold forming and manufacturing method thereof

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of nb microalloyed high-strength and high-hole expansion steel and its production method

A kind of Nb microalloyed high-strength and high-hole reaming steel and its production method, its chemical composition weight percent is: C 0.01-0.05%, Si 0.2-0.6%, Mn: 0.8-1.5%, P≤0.02%, S≤0.005 %, N≤0.008%, Als<0.001%, Ca≤0.0050%, Nb 0.01‑0.08%, Mn / S>250, total oxygen [O] T : 0.007~0.020%, remaining Fe and unavoidable impurities. The present invention selectively adds microalloying elements such as Nb to the steel; during the smelting process, by controlling the basicity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel, and the content of acid-soluble aluminum Als; Strip continuous casting casts the cast strip, and the cast strip directly enters a lower airtight chamber with a non-oxidizing atmosphere, and enters the on-line rolling mill for hot rolling under airtight conditions; the strip is cooled by gas atomization cooling after rolling, and finally The produced steel coils can be used directly as hot-rolled sheets or after pickling-tempering.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin strip steel for thin-walled oil barrel and manufacturing method thereof

The invention discloses a steel strip for a thin-wall oil bucket and a manufacturing method thereof. The manufacturing method comprises the following steps: casting a crystal roller from a cast strip by using a thin strip casting process, subsequently uniformly reinforcing and cooling the cast strip in a mode that dry ice is sprayed at a high pressure, and rapidly cooling the cast strip to be less than 1,280 DEG C, wherein the cooling velocity is 200-300 DEG C / s; when the steel strip is subjected to boron treatment in such a mode, large boron nitride separation is prompted, occurrence of low-melting-point phase B2O3 and separation of fine AlN are prevented, and the purposes of uniformly austenite grains and reducing the yield ratio are achieved; subsequently performing on-line recrystallization and rolling on the austenite; subsequently atomizing and cooling so as to cool down the hot-rolled steel strip; finally coiling the steel strip. By adopting the manufacturing method, the thin-wall with low yield ratio and excellent stamping property for the thin-wall oil bucket is manufactured. The hot-rolled steel strip for the thin-wall oil bucket can be used in hotness instead of coldness, and a cold-rolling procedure is omitted, so that the production cost is greatly lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength and high-reaming steel based on scrap steel and production method thereof

ActiveCN112522596AShort production processImprove efficiencyProcess efficiency improvementSlagMolten steel

The invention discloses high-strength and high-reaming steel based on scrap steel and a production method thereof. The high-strength and high-reaming steel comprises the following chemical componentsof, in percentage by weight, 0.01%-0.05% of C, 0.2%-0.6% of Si, 0.8%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001% of Als, less than or equal to 0.0050% of Ca, 0.01%-0.08% of Nb, and 0.007%-0.02% of total oxygen, one or two elements of 0.1%-0.6% of Cu and 0.005%-0.04% of Sn is included, and the balance Fe and inevitable impurities. According to the steel, the residual Sn and Cu elements in the scrap steel are used for smelting, and microalloy elements such as Nb are selectively added; the alkalinity of slag,a type and a melting point of an inclusion in steel, a content of free oxygen in molten steel and a content of acid-soluble aluminum Als are controlled; and double-roll thin strip continuous castingis adopted for casting a cast strip, the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under the closed condition,a gas atomization cooling mode is adopted for cooling after rolling, and finally coiling is carried out.

Owner:BAOSHAN IRON & STEEL CO LTD

Energy-saving and environmental-friendly decorative lamp for advertising board

InactiveCN103714762ASuitable for implementationTo achieve the purpose of supplyPoint-like light sourceElectric circuit arrangementsElectricityEngineering

The invention discloses an energy-saving and environmental protection decorative lamp for an advertising board. An advertising board is referred. Connecting arms stretch out from the advertising board, the stretching end of each connecting arm is provided with a screw hole used for fixing the lamp which is provided with a lug, the lug is provided with another screw hole corresponding to the screw hole of the connecting arm, lamp units are fixedly connected with the connecting arms through bolts, each lamp unit is provided with an arch base, a plurality of illuminating lamps are installed on each arc base, an outer cover of each lamp unit is provided with a multi-edged transparent sphere, and a solar panel electrically connected with the lamp units is set up on the connecting arms. Through the connecting arms stretching out from the advertising board and the solar panel electrically connected with the lamp units and set up on the connecting arms, solar energy is utilized to generate power for the lamp units, energy saving and environmental friendliness are achieved, and the energy-saving and environmental-friendly decorative lamp is applicable to promotion and implementation.

Owner:XIAN TIANYUNTANG ADVERTISEMENT CULTURAL COMM

Energy-saving environment-friendly decorative lamp for billboard

The invention discloses an energy-saving environment-friendly decorative lamp for a billboard. The lamp includes the billboard and a lamp body; a connecting arm extends out of the billboard, screw holes used for fixing the lamp body are formed in the stretching end of the connecting arm, convex lugs are arranged on the lamp body and provided with screw holes corresponding to the screw holes of theconnecting arm, and the lamp body is fixedly connected with the connecting arm through bolts. The lamp body is internally provided with an arched base, multiple floodlights are installed on the arched base, a multi-edge transparent ball body is arranged on an outer cover of the lamp body, and a solar panel electrically connected with the lamp body is arranged on an upper shelf of the connecting arm. By extending the connecting arm out of the billboard and arranging the solar panel electrically connected with the lamp body on the upper shelf of the connecting arm, the purposes of utilizing solar energy to generate power and supplying power to the lamp body are achieved, the energy is saved, the environment is protected, and the lamp is suitable for application and popularization.

Owner:宁波蔚燃文化传播有限公司

A thin-gauge martensitic steel strip and its manufacturing method

ActiveCN112522633BShort production processImprove efficiencyHeat treatment process controlSmelting processMolten steel

A thin-gauge martensitic steel strip and its manufacturing method, the composition weight percent of which is: C: 0.16‑0.26%, Si: 0.1‑0.5%, Mn: 0.4‑1.7%, P≤0.02%, S≤0.007% , N: 0.004‑0.010%, Als: <0.001%, total oxygen [O] T : 0.007‑0.020%; the balance is Fe and other unavoidable impurities, and at the same time: containing one or both of Cu: 0.1‑0.6% or Sn: 0.005‑0.04%; containing Nb: 0.01‑0.08%, Mo: one or two of 0.1‑0.4%; Mn / S>250. The invention utilizes residual Sn, Cu and other elements in scrap steel to smelt molten steel, and selectively adds microalloying elements such as Nb / Mo to the steel; during the smelting process, the alkalinity of slag, the type of inclusions in steel and the melting point are controlled , free oxygen content in molten steel, and acid-soluble aluminum Als content; then twin-roll thin strip continuous casting is performed to cast the cast strip, which is obtained by online hot rolling and rapid cooling by gas atomization.

Owner:BAOSHAN IRON & STEEL CO LTD

B-containing hot-rolled steel plate/strip with sulfuric acid dew point corrosion resistance and manufacturing method thereof

The invention discloses a B-containing hot-rolled steel plate / strip with sulfuric acid dew point corrosion resistance and a manufacturing method thereof. In the method, microalloy elements such as Cr,Ti, Sb and Cu and an element B are selectively added; in the smelting process, the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled; double-roller thin-strip continuous casting is adopted for casting a cast strip, and the cast strip enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of crystallization rollers and enters an online rolling mill under the closed condition to be subjected to hot rolling; and a gas atomization cooling mode is adopted for cooling strip steel after rolling, and finally the strip steel is coiled. The steel strip produced by the method can be widely applied to the field of products with use environmentsrequiring sulfuric acid dew point corrosion resistance, such as tobacco baking equipment and air preheater heat exchange elements, conveying pipes, flue and chimney manufacturing structural parts andboiler preheater and economizer equipment in the industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

High-hole-expansion steel based on scrap steel raw material and production method thereof

The invention discloses high-hole-expansion steel based on a scrap steel raw material and a production method thereof. The high-hole-expansion steel comprises, by weight, 0.01-0.05% of C, 0.2-0.6% ofSi, 0.8-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001% of Als, less than or equal to 0.0050% of Ca, 0.007-0.02% oftotal oxygen [O]T and the balance Fe and inevitable impurities, and also contains one or two of 0.1-0.6% of Cu and 0.005-0.04% of Sn, wherein the Mn / S ratio is greater than 250. According to the method, the scrap steel is adopted as a raw material, and residual elements such as Sn and Cu in the scrap steel are fully utilized for smelting; the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled; and then, double-roller thin-strip continuous casting is carried out to cast a cast strip, the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of crystallization rollers and enters an online rolling mill under theclosed condition to be subjected to hot rolling, and strip steel obtained after rolling is cooled in a gas atomization cooling mode.

Owner:BAOSHAN IRON & STEEL CO LTD

Nb microalloyed high-strength and high-reaming steel and production method thereof

The invention discloses Nb microalloyed high-strength and high-reaming steel and a production method thereof. The Nb microalloyed high-strength and high-reaming steel comprises the following chemicalcomponents in percentage by weight: 0.01-0.05% of C, 0.2-0.6% of Si, 0.8-1.5% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.008% of N, smaller than 0.001% of Als, smaller than or equal to 0.0050% of Ca, 0.01-0.08% of Nb, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]T and the balance of Fe and inevitable impurities. According to the Nb microalloyed high-strength and high-reaming steel, microalloy elements such as Nb are selectively added into the steel; in the smelting process, the alkalinity of slag, the types and melting points of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled; then a cast strip is cast through twin-roll thin-strip continuous casting, and the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under the closed condition; strip steel iscooled in a gas atomization cooling manner after being rolled; and finally the produced steel coil can be directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com