Thin strip steel for thin-walled oil barrel and manufacturing method thereof

A manufacturing method and technology of thin strip steel, applied in the field of continuous casting process, can solve the problems of low elongation, high yield ratio, poor formability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

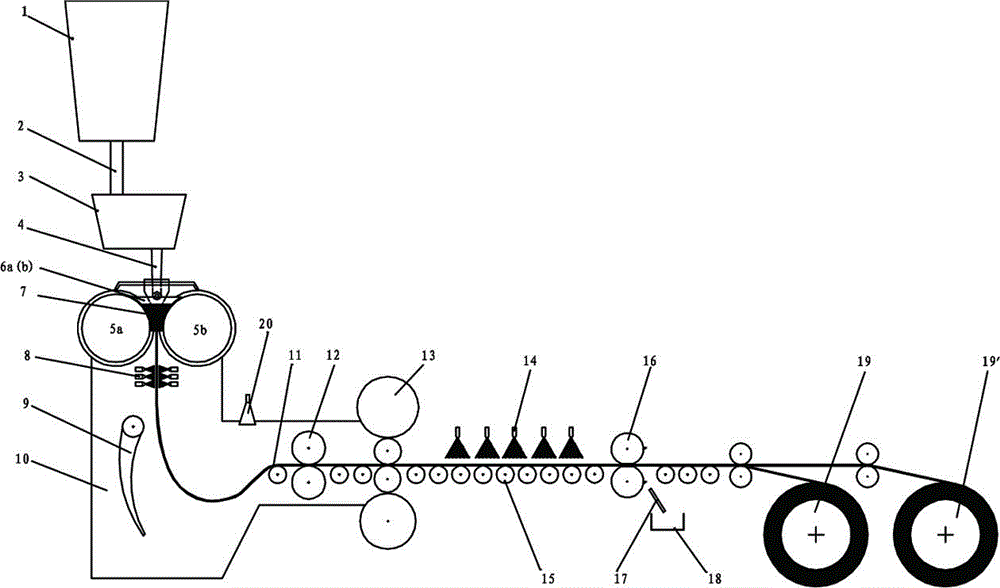

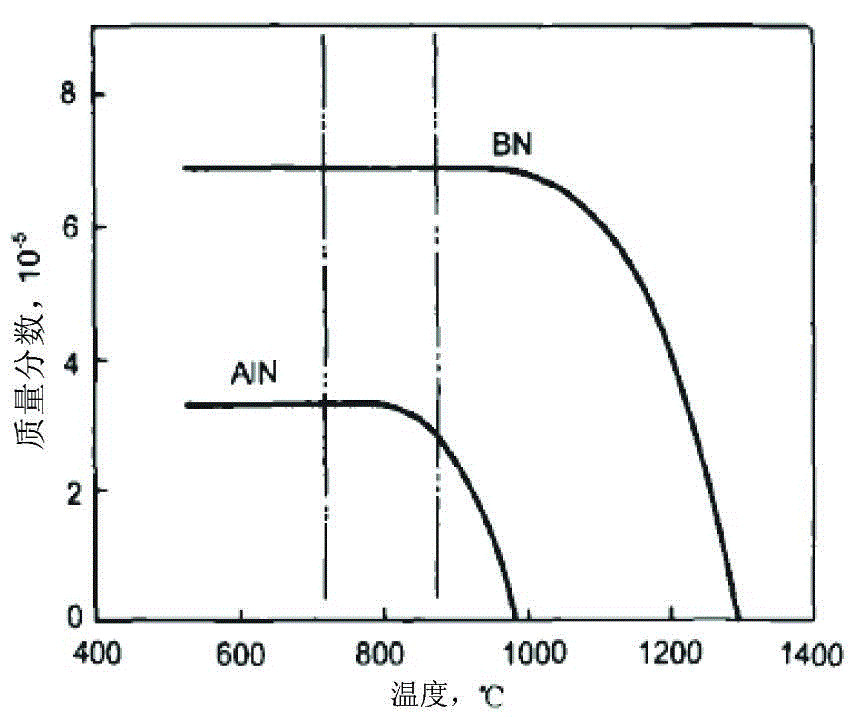

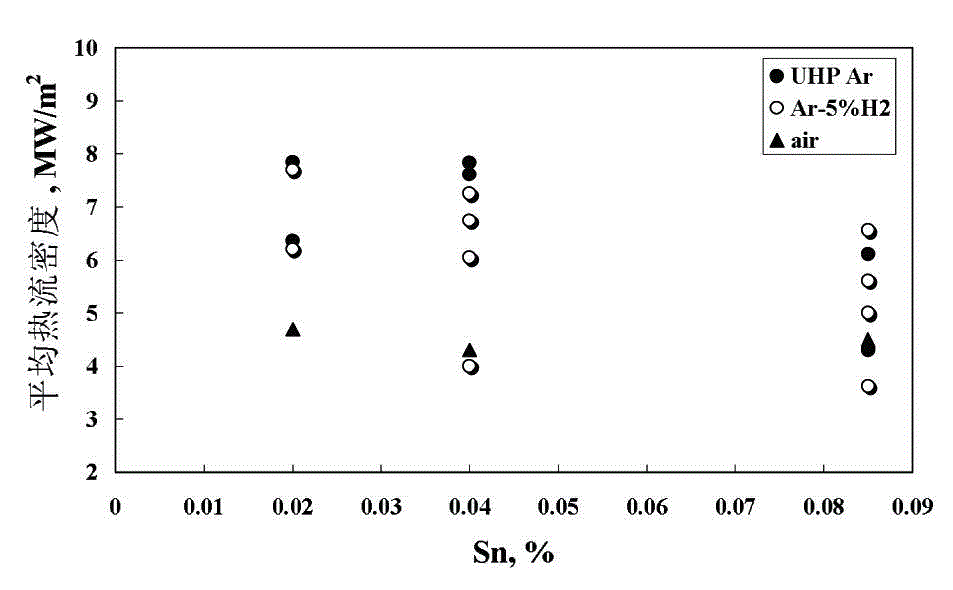

[0081] see figure 1 , the technical process of the present invention, the molten steel is poured through the ladle 1, through the ladle shroud 2, the tundish 3 and the flow distribution device 4 directly on a crystallization roller 5a, 5b and a side sealing plate which are relatively rotating and capable of rapid cooling In the molten pool 7 surrounded by the devices 6a and 6b, molten steel solidifies on the circumferential surface where the crystallization rollers 5a and 5b rotate, and then forms a solidified shell and gradually grows, and then forms a 1.5-3mm shell at the smallest gap (nip point) between the two crystallization rollers. Thick casting band 11, casting band passes through the secondary cooling device 8 in the airtight chamber 10, sprays dry ice (solid CO 2 ), to control the cooling rate, so that the casting belt 11 is rapidly and uniformly cooled to below 1280°C. Then the cast strip is sent to the hot rolling mill 13 through the swing guide plate 9 and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com