High-strength thin strip steel for cold forming and manufacturing method thereof

A manufacturing method and technology of thin strip steel, applied in the direction of metal rolling, etc., can solve the problems of high yield ratio, uneven structure, low elongation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

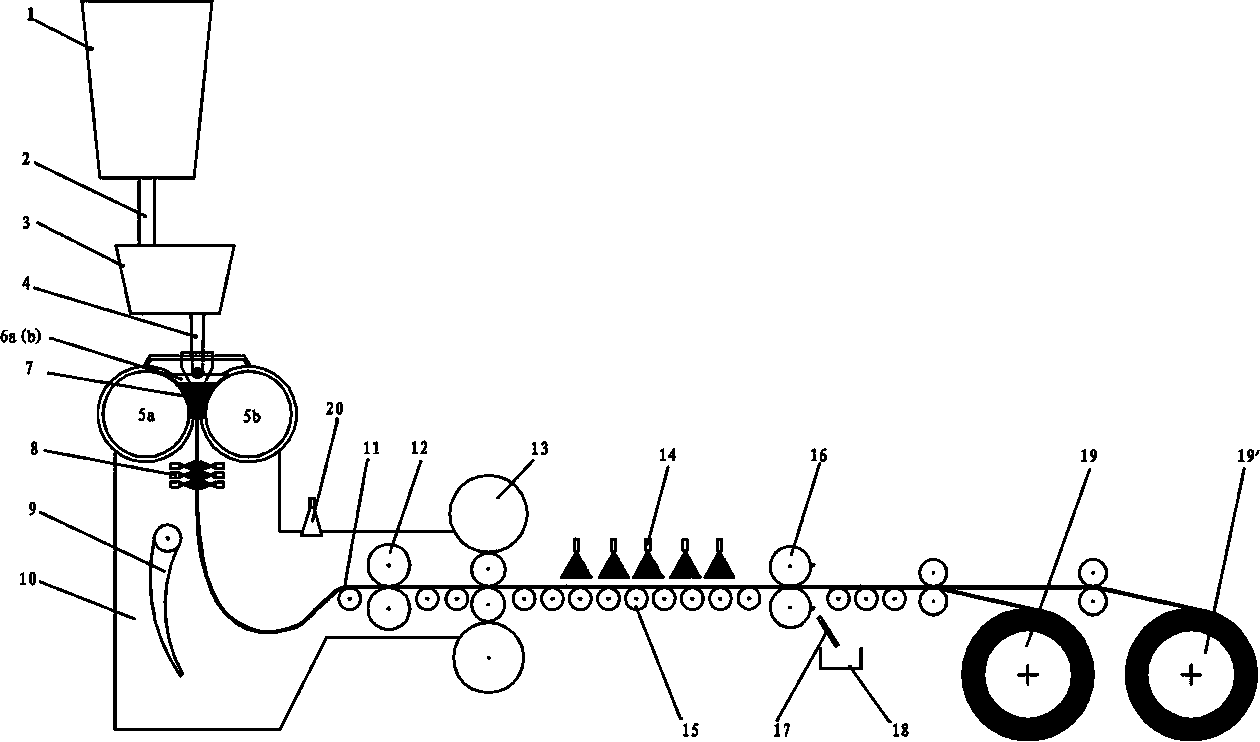

[0095] see figure 1 , which shows the technical process of the present invention, molten steel is poured directly from the ladle 1 through the ladle shroud 2, the tundish 3 and the flow distribution device 4 on a crystallization roller 5a, 5b and 5b which are relatively rotating and capable of rapid cooling. In the molten pool 7 surrounded by the side sealing plate devices 6a, 6b, the molten steel solidifies on the circumferential surface where the crystallization rollers 5a, 5b rotate, and then forms a solidified shell, which gradually grows and then forms at the smallest gap (nip point) between the two crystallization rollers. 1.5-3 mm thick cast strip 11 . The casting strip passes through the secondary cooling device 8 in the airtight chamber 10, and immediately sprays dry ice (solid CO 2 ), to control the cooling rate, so that the cast strip 11 is quickly and uniformly cooled to below 1280°C; then the cast strip is sent to the hot rolling mill 13 through the swing guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com