Coating material with abrasion-resistant and cavitation-damage-prevention functions and preparation method thereof

A coating material and anti-wear technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problem that anti-wear and anti-cavitation cannot be unified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

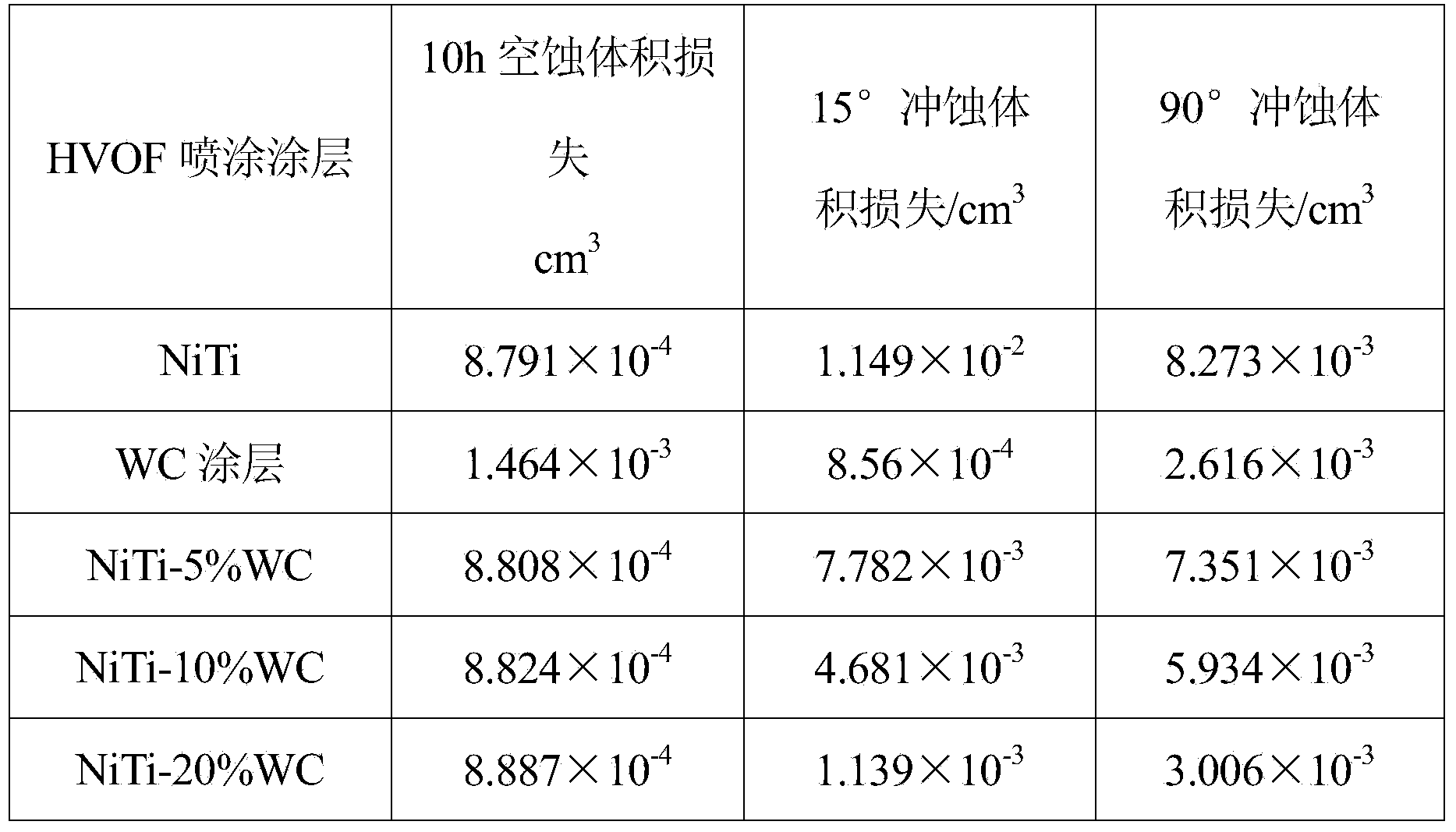

[0014] Embodiment 1: the free state nanometer WC hard phase particle (about 50 nanometers) that accounts for total weight 5wt%, 10wt%, 20wt% respectively is mixed with the NiTi powder body material with CsCl type body centered cubic B2 structure, in low temperature ball milling Ball milling is carried out under the process, and after ball milling for 25 hours, the particle size of the powder is controlled at 10-100 microns by particle size screening to obtain WC particle-reinforced NiTi composite coating powder materials that can be used for supersonic flame spraying and plasma spraying. The cavitation erosion performance and wear performance of the coating after supersonic flame spraying are shown in Table 1. After adding nano-WC particles, the cavitation volume loss of NiTi alloy did not increase significantly, but at 15° and 90°, using 100M After the brown corundum is subjected to erosion wear, its erosion damage volume is significantly reduced, which is close to the erosion...

Embodiment 2

[0015] Embodiment 2: with NiTi metal wire material, wire material is melted and atomized and sprayed in distilled water by arc spraying process, obtains the powder particle of NiTi phase, then it is carried out with the nanometer WC hard phase particle that accounts for total weight 5wt% Mixing, through low-temperature ball milling technology, mechanical alloying for 25 hours, through particle size sieving, the powder particle size is controlled at 10-100 microns, and WC particle-reinforced NiTi composite coating powder materials that can be used for supersonic flame spraying and plasma spraying are obtained .

Embodiment 3

[0016] Example 3: Mix the submicron WC hard phase particles accounting for 5wt% of the total weight with the NiTi powder material having a CsCl-type body-centered cubic B2 structure, and perform ball milling under a low-temperature ball milling process. After ball milling for 25 hours, pass through a particle size sieve The particle size of the powder is controlled at 10-100 microns, and the WC particle-reinforced NiTi composite coating powder material that can be used for supersonic flame spraying and plasma spraying is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com