Copper-aluminum-manganese-beryllium memory superelasticity alloy and producing method thereof

A technology of superelastic alloys and production methods, which is applied in the field of memory alloys and can solve problems such as high prices, low superelasticity, and poor memory capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using ZG25 vacuum electric furnace, under the pressure of -0.1MPa argon, melt 150mm CuAlMnBe memory super-elastic master alloy ingot to get ingot. The analysis composition of memory super-elastic master alloy ingot is Al10%, Mn8%, Be0.3% , the remainder is Cu;

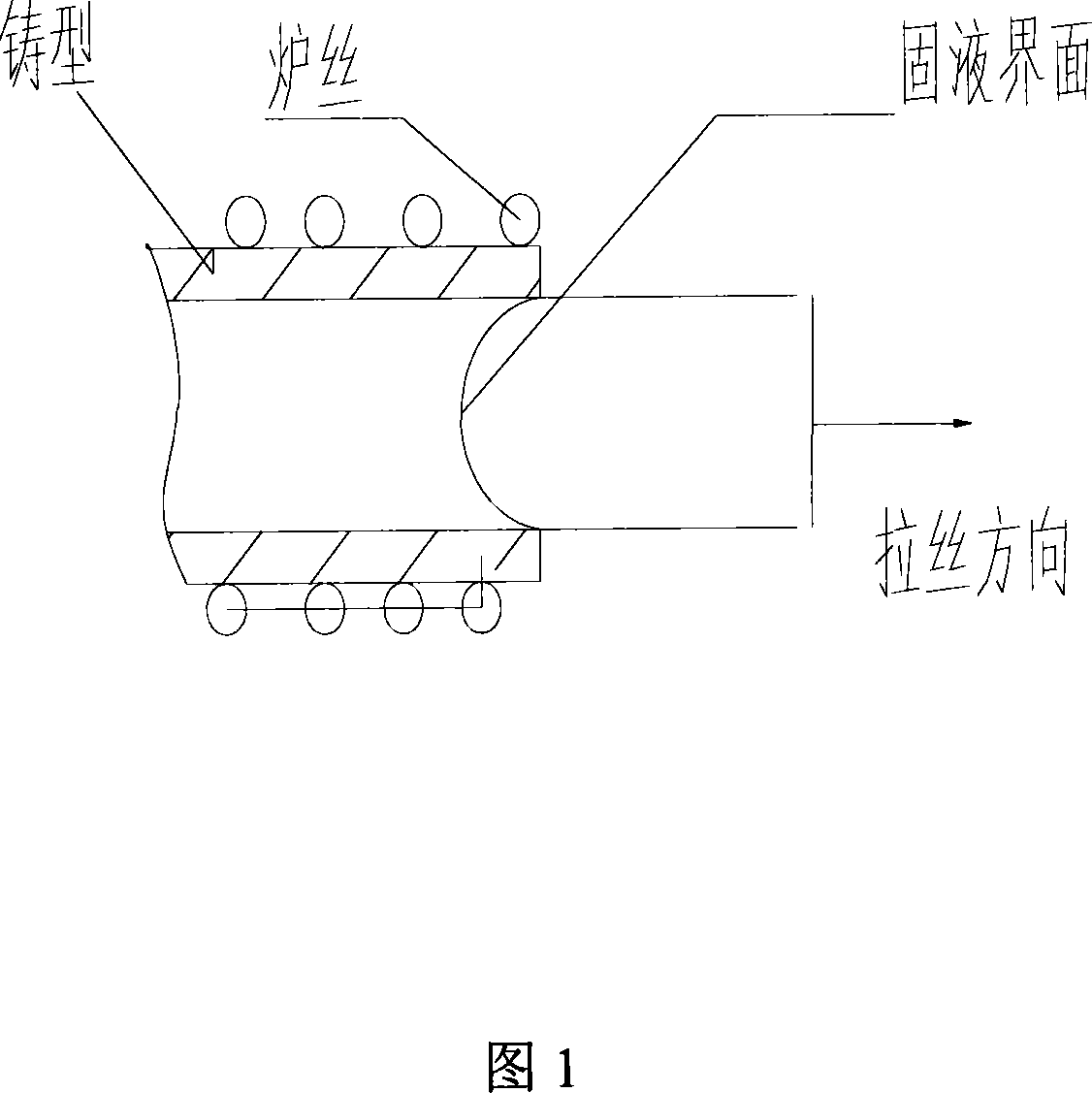

[0018] Using hot-type continuous casting technology, the ingot is drawn into 1.6mm wire semi-finished products, as shown in Figure 1.

[0019] The heat treatment of the semi-finished wire material is as follows: homogenize at 860-920°C for 10 hours ± 0.5 hours, then cool in the air, then keep warm at 880-900°C for 100-150 seconds per mm effective thickness of the sample, and quench in water below 30°C —— followed by aging precipitation at 550-650°C for 20-100 seconds per mm of sample effective thickness; ——finally, heat preservation at 750-880°C for 20-100 seconds per mm of sample effective thickness. The obtained finished wire with 1.6 has a superelastic memory deformation of 25%. The price of raw material...

Embodiment 2

[0021] Use a ZG25 vacuum electric furnace to melt 150mm CuAlMnBe superelastic memory alloy ingot under the hydrogen pressure of -0.1MPa. The analysis composition of the memory superelastic master alloy ingot is Al 11%, Mn6%, Be0.35%, and the remainder is Cu. Homogenize the ingot at 850°C for 10 hours, cut off the skin, hot-roll it at 750°C to form a 6mm round wire, and then hot-draw it at 650°C to form a 1.6mm wire. After heat treatment, the finished product is 1.6 mm wire has an elongation of 13% and a superelastic deformation of 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com