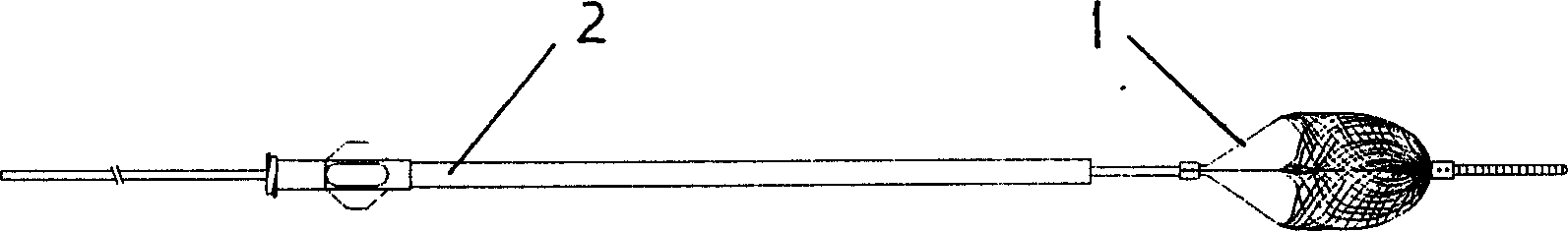

Far end protecting device and its preparing method

A protector and distal technology, applied in medical science, catheters, surgery, etc., can solve problems such as thrombus shedding, stenosis, and affecting blood supply to distal tissues, and achieve the effect of reducing the overall size, safe and effective surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

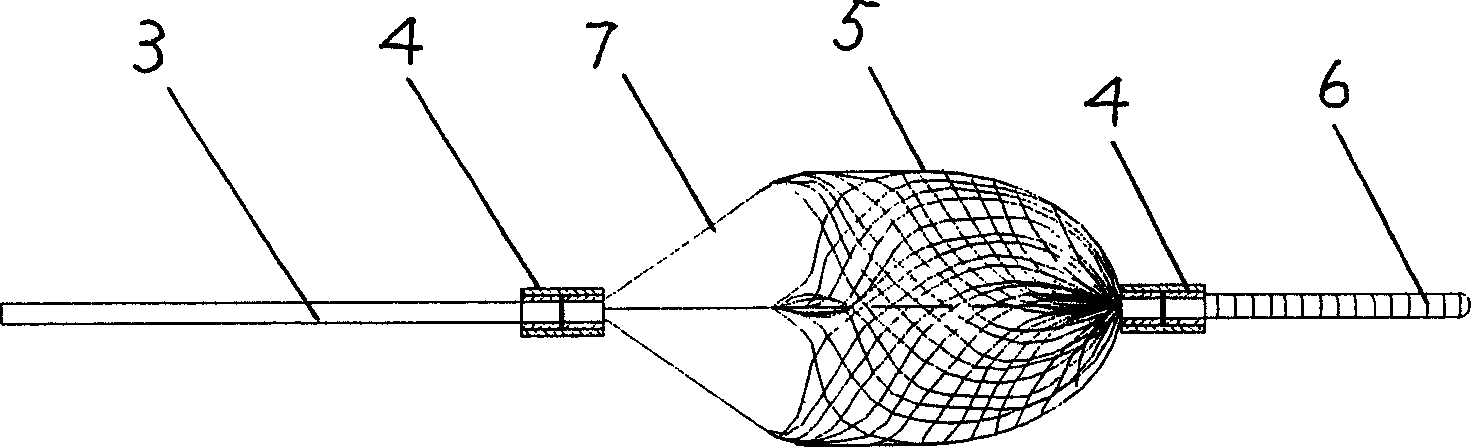

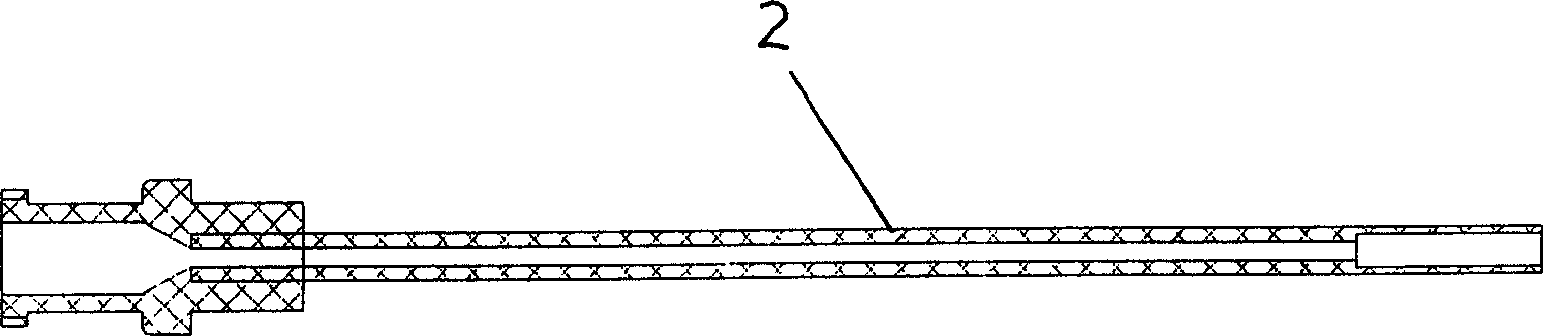

[0047] Preparation of net blue: use 68 NiTi alloy wires with a diameter of 0.08mm and 4 platinum wires with a diameter of 0.08mm to weave on the HTBZ-40 braiding machine manufactured by Shenzhen Huitai Medical Instrument Co., Ltd. Figure 6 As shown in the mesh tube, the platinum wire is evenly distributed on the mesh tube; divide one end of the mesh tube into four basket legs, and then wrap it in a shape such as Figure 9 Outside the mandrel, put the mandrel covered with mesh tube into the shape as Figure 10 Inside the outer mold, the outer mold is covered with a shape such as Figure 11 mold cover; such as Figure 12 As shown, put the mold with the mesh tube into the ZSK2-12-6 vacuum heat treatment furnace manufactured by Wuhan Industrial Electric Furnace General Factory, and keep it warm for 10 minutes at 450°C; Put it into the casing, weld the basket and the casing on the LCT-W1 laser welding machine manufactured by Beijing Laize Optoelectronics Technology Co., Ltd. to ...

Embodiment 2

[0051] Preparation of net blue: use 68 NiTi alloy wires with a diameter of 0.08mm and 4 platinum wires with a diameter of 0.08mm to weave on the HTBZ-40 braiding machine manufactured by Shenzhen Huitai Medical Instrument Co., Ltd. Figure 6 As shown in the mesh tube, the platinum wire is evenly distributed on the mesh tube; divide one end of the mesh tube into four basket legs, and then put it on Figure 9 Outside the mandrel, put the mandrel covered with mesh tube into the shape as Figure 10 Inside the outer mold, the outer mold is covered with a shape such as Figure 11 mold cover; such as Figure 12 As shown in the figure, put the mold with the mesh tube into the ZSK2-12-6 vacuum heat treatment furnace manufactured by Wuhan Industrial Electric Furnace General Factory, and keep it warm for 10 minutes at 550°C; Put it into the casing, weld the basket and the casing on the LCT-W1 laser welding machine manufactured by Beijing Laize Optoelectronics Technology Co., Ltd. to mak...

Embodiment 3

[0055] Preparation of net blue: use 68 NiTi alloy wires with a diameter of 0.08mm and 4 platinum wires with a diameter of 0.08mm to weave on the HTBZ-40 braiding machine manufactured by Shenzhen Huitai Medical Instrument Co., Ltd. Figure 6 As shown in the mesh tube, the platinum wire is evenly distributed on the mesh tube; divide one end of the mesh tube into four basket legs, and then put it on Figure 9 Outside the mandrel, put the mandrel covered with mesh tube into the shape as Figure 10 Inside the outer mold, the outer mold is covered with a shape such as Figure 11 mold cover; such as Figure 12 As shown, put the mold with mesh tube into the ZSK2-12-6 vacuum heat treatment furnace manufactured by Wuhan Industrial Electric Furnace General Factory, and keep it warm for 10 minutes at 530°C; Put it into the casing, weld the basket and the casing on the LCT-W1 laser welding machine manufactured by Beijing Laize Optoelectronics Technology Co., Ltd. to make a complete mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com