Method of preparing ultra-long Ni-Ti-O nano tube on surface of NiTi alloy

A ni-ti-o, nanotube technology, applied in the field of nanomaterial preparation, can solve problems such as limited length of nanotubes, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

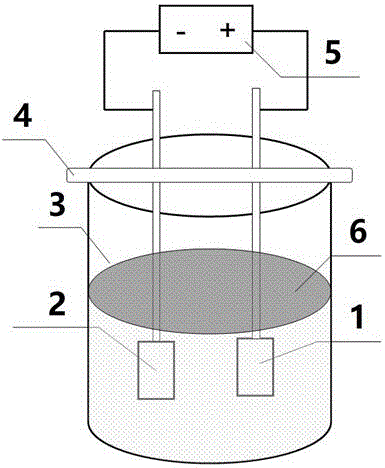

[0023] Now test the NiTi alloy specimen 1 containing 50.8at% Ni with a diameter of 7.5mm and a thickness of 2mm. The alloy specimen is used as the workpiece electrode, and the graphite rod auxiliary electrode 2 is placed in the electrolytic cell 3. The electrolytic cell 3 It is the ethylene glycol electrolyte 6, the workpiece electrode and the auxiliary electrode are fixed by the bracket 4 on the top of the electrolytic cell, and are respectively connected to the anode and the cathode of the DC power supply 5.

[0024] The specific steps are as follows:

[0025] (1) Pretreatment of NiTi alloy specimens: NiTi alloy specimens are mechanically ground and polished, and then immersed in acetone, alcohol and distilled water for ultrasonic cleaning for 10 minutes to obtain pretreated NiTi alloy specimens;

[0026] (2) Concentrated hydrochloric acid containing 4.2vol% (mass fraction of 37%), 2vol% H 2 Put the O glycol electrolyte 6 into the electrolytic cell 3, fix the auxiliary electrode 2 ...

Embodiment 2

[0029] Now test the NiTi alloy specimen 1 containing 50.8at% Ni with a diameter of 7.5mm and a thickness of 2mm. The alloy specimen is used as the workpiece electrode, and the graphite rod auxiliary electrode 2 is placed in the electrolytic cell 3. The electrolytic cell 3 It is the ethylene glycol electrolyte 6, the workpiece electrode and the auxiliary electrode are fixed by the bracket 4 on the top of the electrolytic cell, and are respectively connected to the anode and the cathode of the DC power supply 5.

[0030] The specific steps are as follows:

[0031] (1) Pretreatment of NiTi alloy specimens: NiTi alloy specimens are mechanically ground and polished, and then immersed in acetone, alcohol and distilled water for ultrasonic cleaning for 10 minutes to obtain pretreated NiTi alloy specimens;

[0032] (2) Concentrated hydrochloric acid containing 4.2vol% (mass fraction of 37%), 8.0vol% H 2 Put the O glycol electrolyte 6 into the electrolytic cell 3, fix the auxiliary electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com