Preparation method of porous NiTi alloy

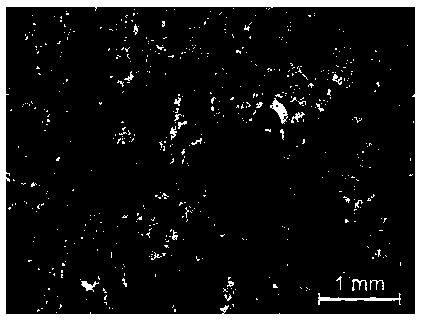

A technology of alloy and mixed powder, which is applied in the preparation of porous NiTi alloy. The self-propagating process is used to prepare porous NiTi alloy. It can solve the problems of many heterogeneous phases, uneven pore structure, and difficult reaction control, etc., and achieve high porosity, Uniform pore size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using Ti powder with a particle size of ≤75 microns and Ni powder with a particle size of ≤45 microns as raw materials, weigh the powders according to the molar ratio of Ni powder:Ti powder=50.5:49.5, put them into a conical mixer and mix for 8 hours to obtain Ni / Ti mixed powder; the gained Ni / Ti mixed powder is put into the ball mill tank, add the paraffin wax of Ni / Ti mixed powder gross mass 0.4%, ball mill 20h under the rotating speed of 400 rev / mins, cross 200 mesh sieves, obtain Ni / Ti mixed powder Ti ball mill powder; put Ni / Ti ball mill powder into a ceramic boat, put it into a vacuum furnace for degreasing, and maintain the vacuum degree in the furnace ≤1×10 during the whole degreasing period -1 MPa, degreasing temperature 200 ° C, degreasing time 3h, to obtain Ni / Ti degreasing powder; according to the mass ratio Ni / Ti degreasing powder: Ni / Ti mixed powder=30:70, put it in a cone mixer and mix for 8h to obtain Ni / Ti working powder; put Ni / Ti working powder int...

Embodiment 2

[0029] Using Ti powder with a particle size of ≤75 microns and Ni powder with a particle size of ≤45 microns as raw materials, weigh the powders according to the molar ratio of Ni powder:Ti powder=50.5:49.5, put them into a conical mixer and mix for 4 hours to obtain Ni / Ti mixed powder; the gained Ni / Ti mixed powder is put into a ball mill jar, add the stearic acid of Ni / Ti mixed powder gross mass 0.8%, ball mill 40h under the rotating speed of 300 rev / mins, cross 200 mesh sieves, obtain Ni / Ti ball milling powder; put the Ni / Ti ball milling powder into a ceramic boat, put it into a vacuum furnace for degreasing, and keep the vacuum degree in the furnace ≤1×10 during the whole degreasing period-1 MPa, degreasing temperature 300 ° C, degreasing time 1h, to obtain Ni / Ti degreasing powder; according to the mass ratio Ni / Ti degreasing powder: Ni / Ti mixed powder = 20:80, put it in a cone mixer and mix for 4 hours to obtain Ni / Ti working powder; put Ni / Ti working powder into a cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com