Recoverable energy absorption structure and preparation method thereof

An energy-absorbing structure and duplex technology, applied in mechanical equipment, vibration suppression adjustment, additive processing, etc., can solve the problems of traditional energy-absorbing structures that cannot be reused and difficult to prepare by traditional processes, and achieve high forming accuracy and excellent mechanical properties. , the effect of high energy absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] An embodiment of the present invention provides a preparation method based on the recoverable energy-absorbing structure, the method comprising:

[0056] Build an energy-absorbing structure model;

[0057] Input the energy-absorbing structure model into the 3D printer, and adjust the relevant parameters of the 3D printer;

[0058] Put NiTi alloy powder into the 3D printer box, and print the energy-absorbing structure after the 3D printer is preheated;

[0059] Heat treatment of the printed energy-absorbing structure to adjust the M→B of the NiTi alloy 2 phase transition temperature.

Embodiment example 1

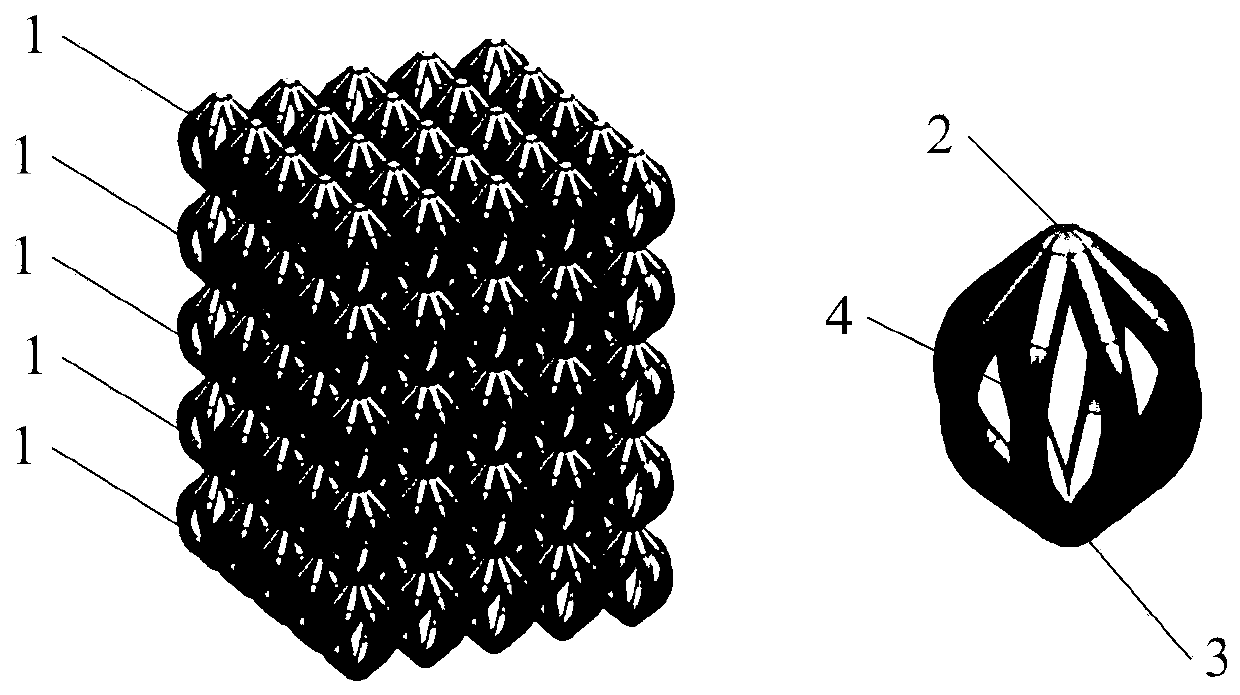

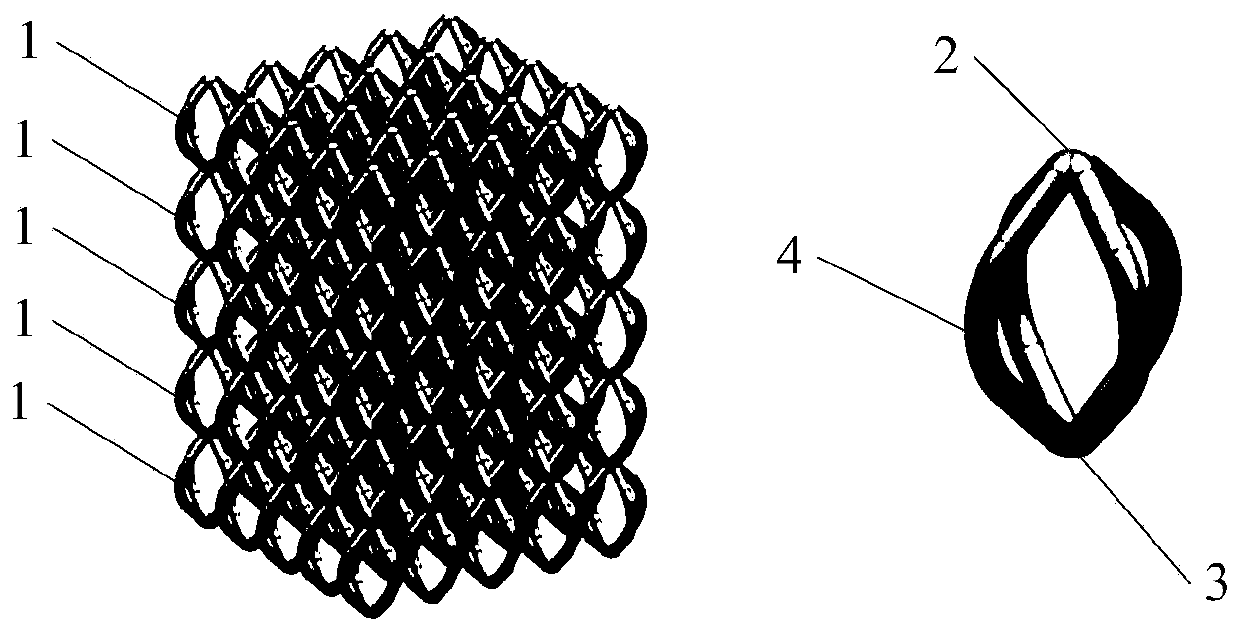

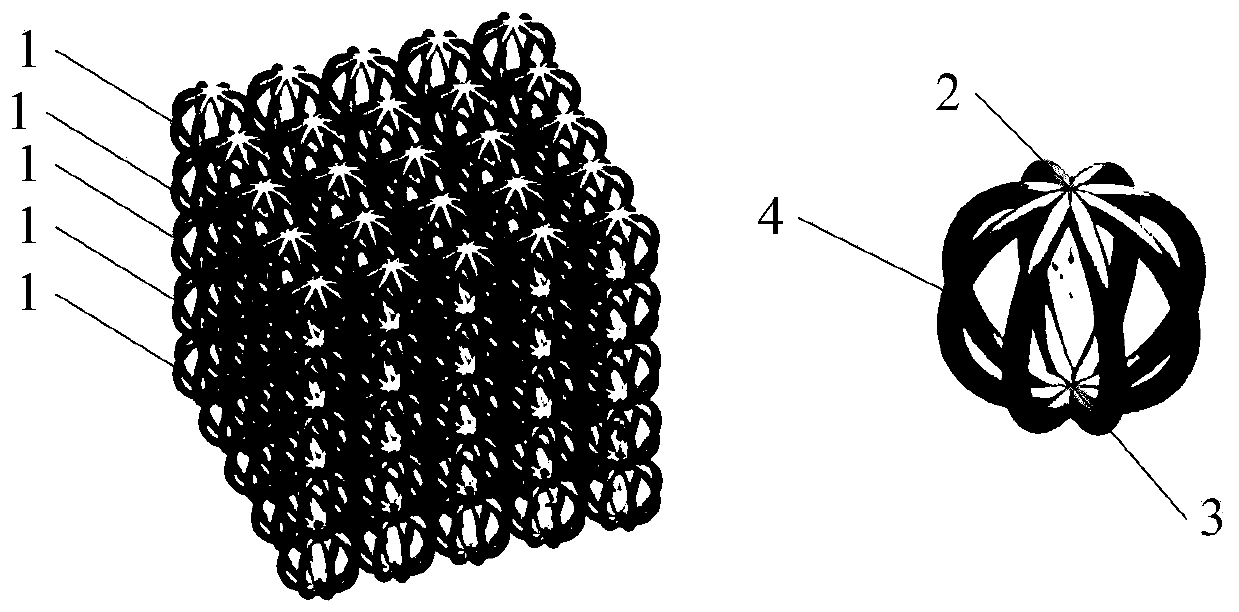

[0061] Please refer to Figure 5-Figure 9 , built with UG software figure 2 In the two-ring structure model (10mm×10mm×10mm), the diameter of the ring rod is adjusted to 0.6mm, and the porosity is about 85%, and the model is imported into the host control system of the 3D printer. Adjust the printing parameters, using laser power of 50W, scanning speed of 800mm / s, layer thickness of 0.02mm, interlayer angle of 67°, and scanning distance of 0.10mm (this parameter is an optimized parameter found out according to the experiment, and the performance of the printed structural parts is stable. better formability). Select NiTi powder with an atomic percentage of Ni49% to 51%, Ti49% to 51% (this composition range has excellent formability, elasticity and recovery performance after heat treatment), and fill the powder into the powder box to carry out the pre-processing of the printer. Heat and chamber atmosphere regulation. After the preparatory work is completed, start to print th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com