Nano coating combined with micropore surface method for modifying endovascular stent

A nano-coating and stent technology, used in coatings, stents, medical science and other directions, can solve the problems of vascular endothelial injury and the incomplete understanding of the mechanism of postoperative ISR, and achieve a simple and easy-to-use material for inhibiting intimal hyperplasia. Effect of surface properties, good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Immerse the NiTi alloy or 316L stainless steel intravascular stent in acetone solution, ultrasonically clean it for 5 minutes, take out the stent and rinse it with distilled water three times;

[0022] (2) Configure 30% HNO 3 Solution (volume percentage);

[0023] (3) Immerse the cleaned stent into 30% HNO 3 In the solution container, place the container in a water bath at a constant temperature of 40°C for 24 hours.

[0024] (4) Take out the stent, clean it ultrasonically with acetone for 5 minutes and clean it three times with distilled water, and dry it at room temperature;

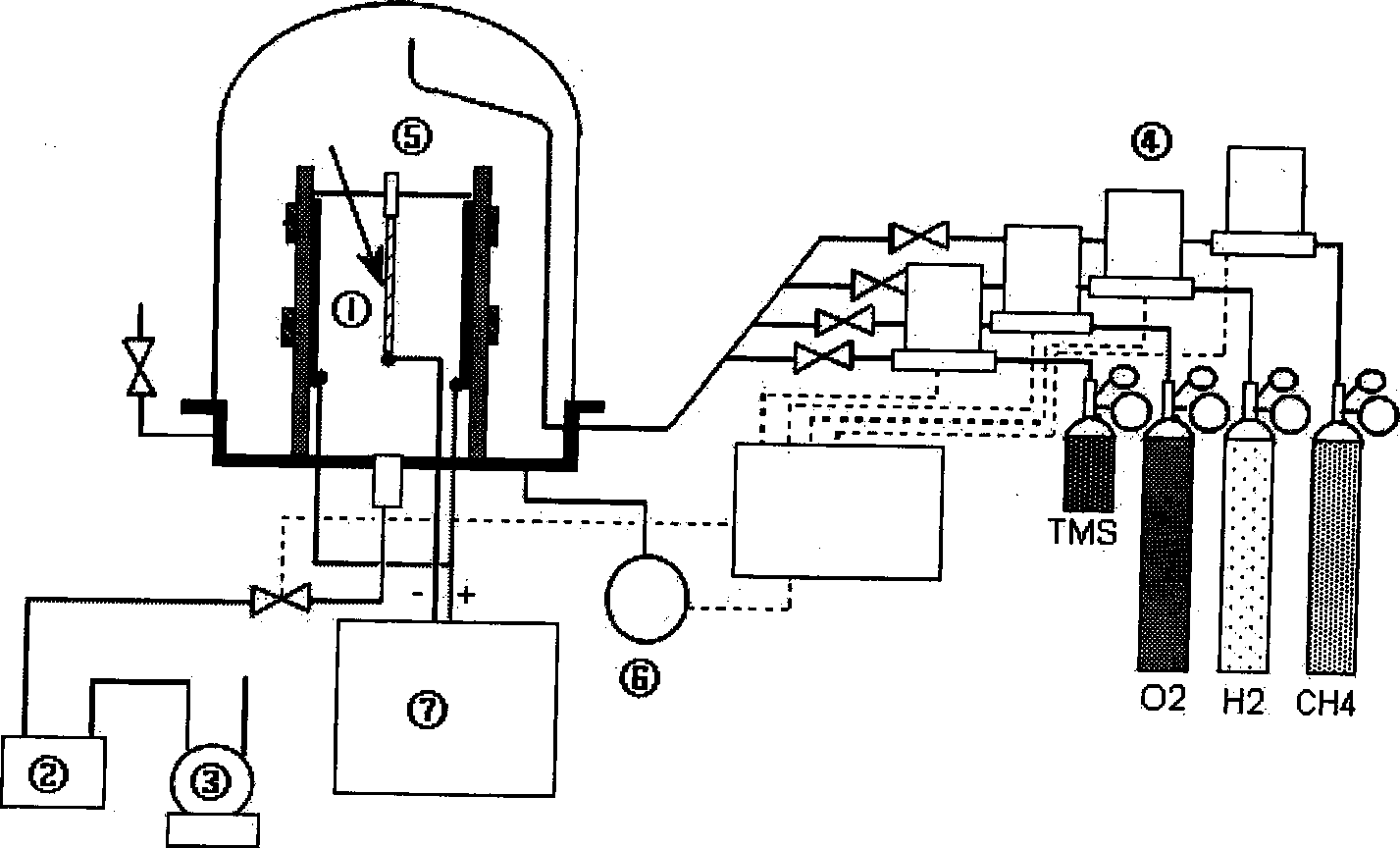

[0025] (5) Place the stent as a cathode material figure 1 On the stainless steel substrate ① in the bell-type plasma reactor;

[0026] (6) Turn on the first and second vacuum pumps ② and ③ to extract the vacuum, and then pass the TMS or O and O into the bell plasma reaction chamber ⑤ through the flow rate controller ④ 2 Adjust the pressure in the reaction chamber through the pressure controller...

Embodiment 2

[0033] Steps (1)-(5) are the same as in Example 1;

[0034](6) Turn on the first and second vacuum pumps ② and ③ to extract vacuum, and then pass the TMS and CH into the bell plasma reaction chamber ⑤ through the flow rate controller ④ 4 And O 2 . SiO can be obtained according to the realization method shown in Table 2 x :H nano coating;

[0035] Table II

[0036] In turn

Incoming monomer Flow rate

(sccm) Reaction pressure (mtorr)

Reaction time (min)

DC power supply

Power (W) TMS 2 25 2 5 CH 4 1 25 1 5 O 2 2 50 2 5

[0037] (7) Determination of deposited SiO x :H nano-coating thickness and water contact angle; SEM, AFM measured the surface morphology of the stent before and after modification, FTIR measured the surface chemical group, the in vitro endothelial cell adhesion experiment was equivalent to Example 1.

[0038] The average roughness Ra of the surface of the scaffold material obtained by the methods of the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com