Method for preparing super-elastic gradient-porosity porous NiTi alloy

A gradient pore and superelastic technology, which is applied in the field of preparation of porous NiTi shape memory alloy and gradient pore porous NiTi shape memory alloy, can solve the problem of continuous gradient pore porous NiTi alloy and achieve good mechanical properties and superelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

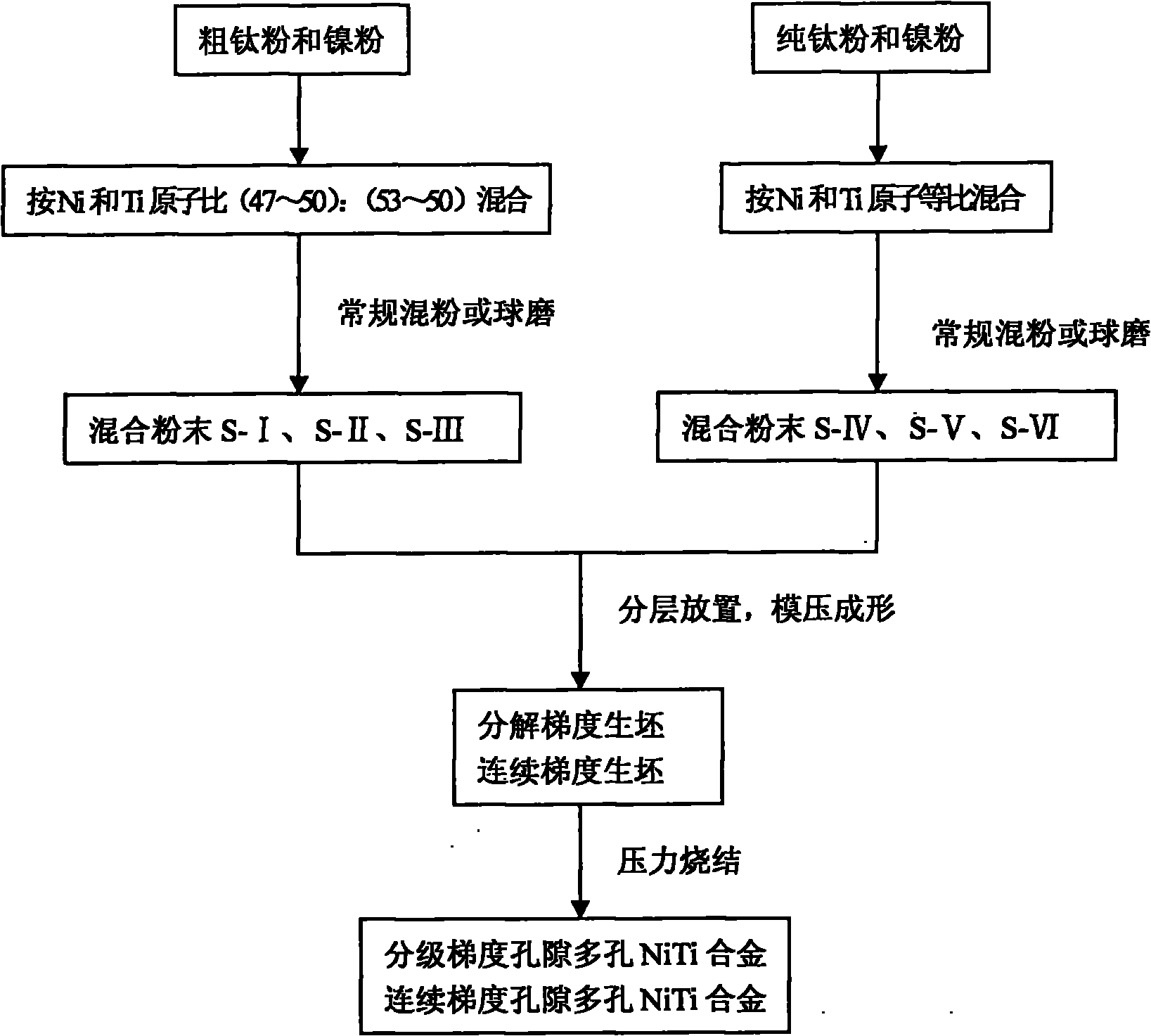

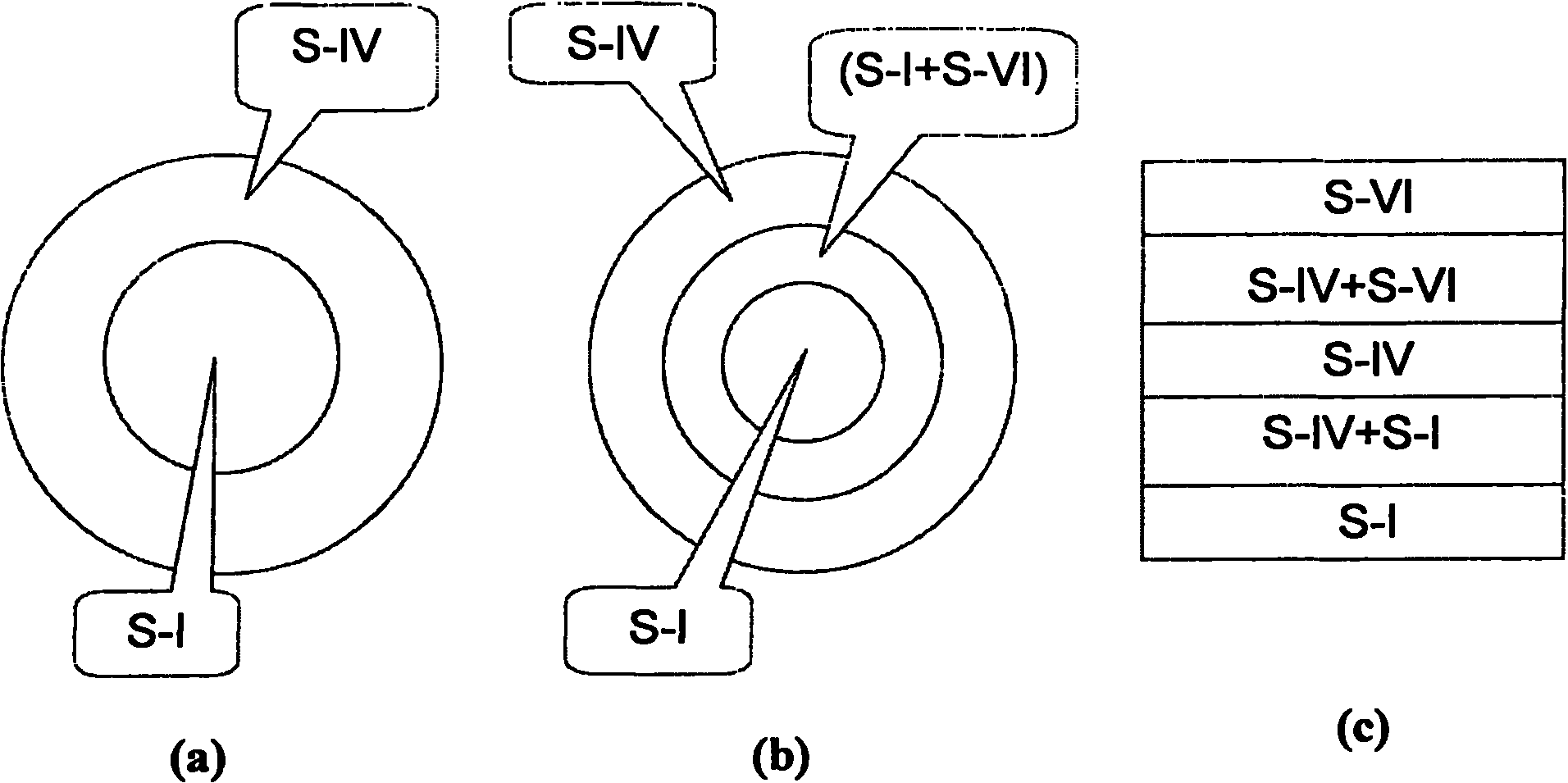

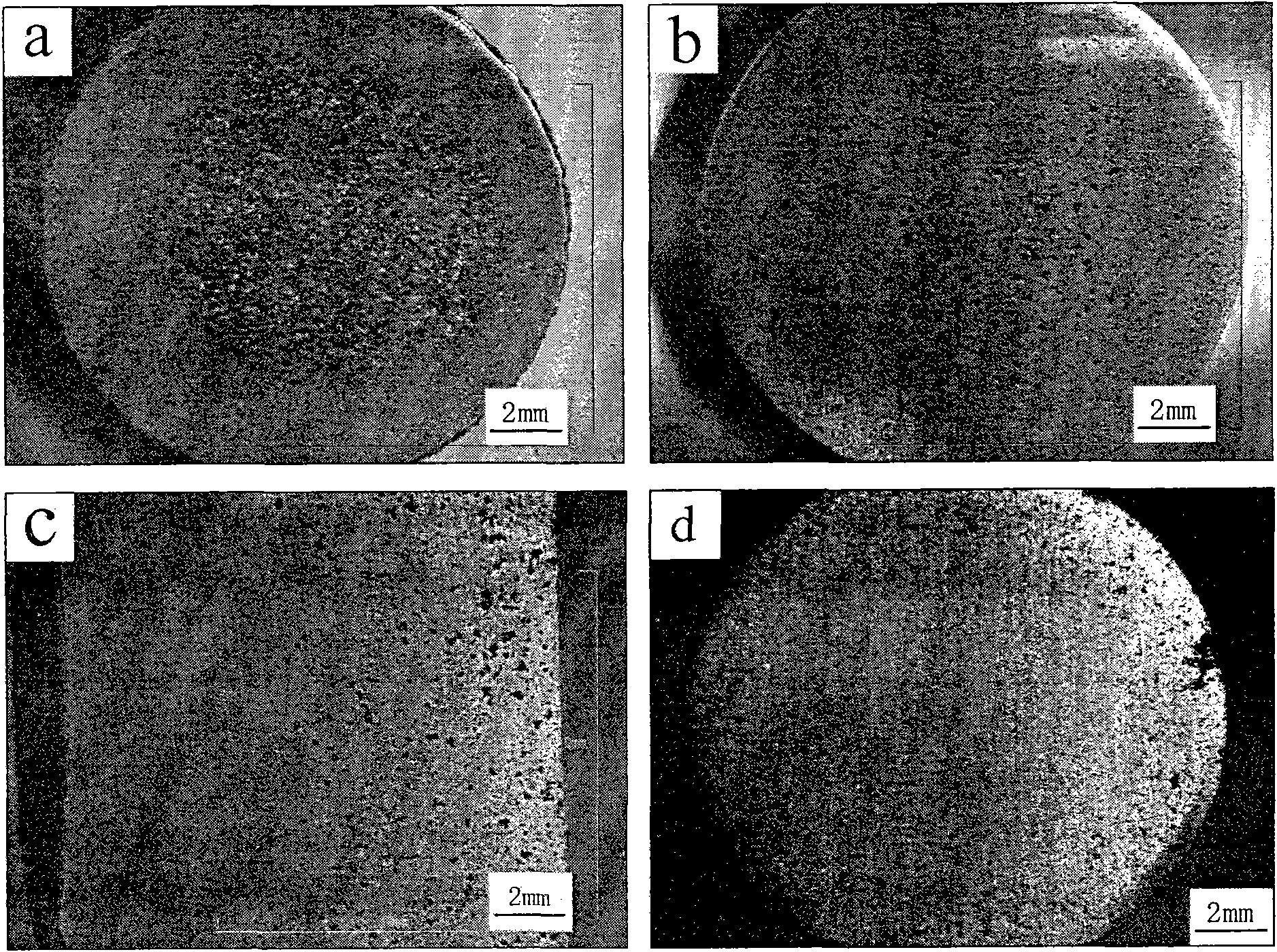

[0032] Embodiment 1: (process flow such as figure 1 shown)

[0033] (1) Coarse titanium powder (containing the TiH of mass percentage concentration 30%) 2 , particle size 50~75 μm) and nickel powder are mixed according to the ratio of Ti atom and Ni atom ratio of 49.2:50.8 by ball milling method to obtain mixed powder 1; the particle size of the nickel powder is 70~80 μm, mixed powder 1 is numbered as S-I; the particle size of the nickel powder is 30-40 μm, and the number of the mixed powder 1 is S-II; the particle size of the nickel powder is 2-3 μm, and the number of the mixed powder 1 is S-III;

[0034] Mix pure titanium powder (purity is 99%, particle size 50-75 μm) and nickel powder according to the same atomic ratio of Ti and Ni to obtain mixed powder 2; the particle size of the nickel powder is 70-80 μm, and the number of mixed powder 2 is is S-IV; the particle size of the nickel powder is 30-40 μm, and the mixed powder 2 is numbered S-V; the particle size of the nick...

Embodiment 2

[0040] (1) thick titanium powder (containing the TiH of mass percentage concentration 40%) 2 , particle size 50~75 μm) and nickel powder are mixed according to the ratio of Ti atom and Ni atom ratio of 48:52 by ball milling method to obtain mixed powder 1; the particle size of the nickel powder is 70~80 μm, mixed powder 1 is numbered as S-I; the particle size of the nickel powder is 30-40 μm, and the number of the mixed powder 1 is S-II; the particle size of the nickel powder is 2-3 μm, and the number of the mixed powder 1 is S-III;

[0041]Mix pure titanium powder (purity is 99%, particle size 50-75 μm) and nickel powder according to the same atomic ratio of Ti and Ni to obtain mixed powder 2; the particle size of the nickel powder is 70-80 μm, and the number of mixed powder 2 is is S-IV; the particle size of the nickel powder is 30-40 μm, and the mixed powder 2 is numbered S-V; the particle size of the nickel powder is 2-3 μm, and the mixed powder 2 is numbered S-VI;

[004...

Embodiment 3

[0047] (1) Coarse titanium powder (containing the TiH of mass percent concentration 50%) 2 , particle size 50-75 μm) and nickel powder are mixed according to the ratio of Ti atom and Ni atom ratio of 47:53 by ball milling method to obtain mixed powder 1; the particle size of the nickel powder is 70-80 μm, and the number of mixed powder 1 is S-I; the particle size of the nickel powder is 30-40 μm, and the number of the mixed powder 1 is S-II; the particle size of the nickel powder is 2-3 μm, and the number of the mixed powder 1 is S-III;

[0048] Mix pure titanium powder (purity is 99%, particle size 50-75 μm) and nickel powder according to the same atomic ratio of Ti and Ni to obtain mixed powder 2; the particle size of the nickel powder is 70-80 μm, and the number of mixed powder 2 is is S-IV; the particle size of the nickel powder is 30-40 μm, and the mixed powder 2 is numbered S-V; the particle size of the nickel powder is 2-3 μm, and the mixed powder 2 is numbered S-VI;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com