Plating liquid for nickel-titanium alloy to coat nickel, cobalt and tungsten through chemical technology and technique method

A technology of chemical plating solution and chemical nickel plating, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., and can solve problems such as no literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

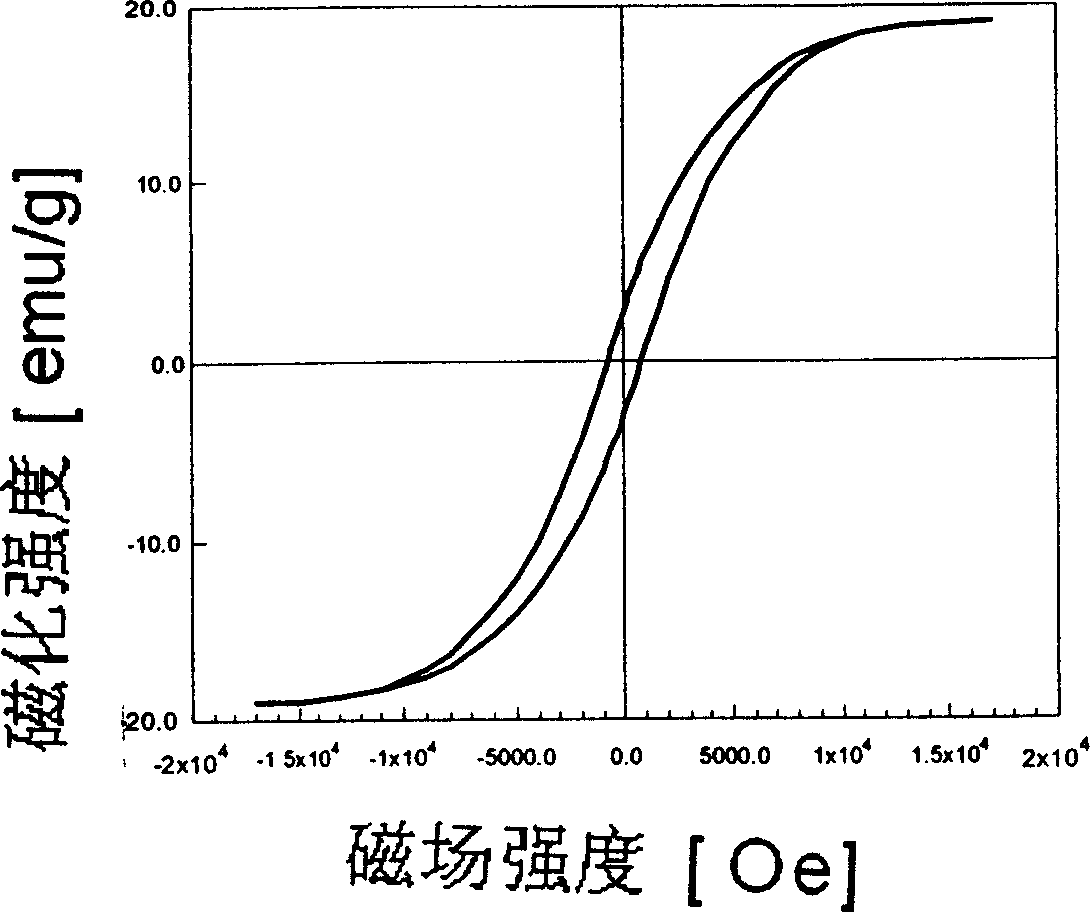

Embodiment 1

[0027] The preparation of No. 1 electroless plating solution, its preparation step is:

[0028] 1. Weigh sodium citrate (Na 3 C 6 h 5 o 2 )26.0g and ammonium sulfate ((NH 4 ) 2 SO 4 ) 40.0g was added into a beaker, and dissolved in 300ml of distilled water to obtain a solution;

[0029] 2. Weigh the metered nickel sulfate (NiSO 4 ·6H 2 O) 5.0g, cobalt sulfate (CoSO 4 ·6H 2 O) 23.0g, sodium tungstate (Na 2 WO 4 ) 0.3g was added to the beaker in turn, and dissolved in 400ml of distilled water to obtain a solution;

[0030] 3. Add the solution obtained in step 2 into the solution obtained in step 1 under stirring to obtain a mixed solution;

[0031] 4. Weigh sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 17.0g was added into a beaker, and dissolved in 200ml of distilled water to obtain a solution;

[0032] 5. Slowly add the solution obtained in step 4 into the mixed solution obtained in step 3 under stirring to obtain a mixed solution;

[0033] 6. Use 15wt% ammonia wa...

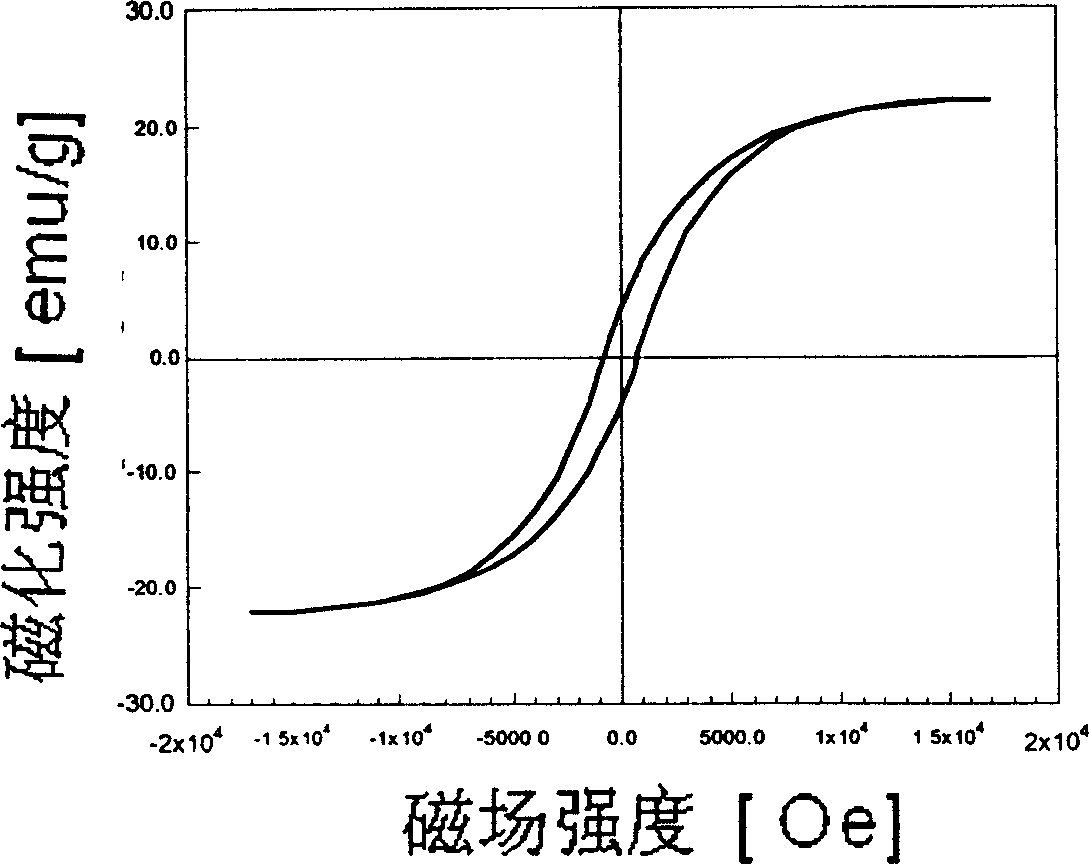

Embodiment 2

[0035] The preparation of No. 2 electroless plating solution, its preparation steps are:

[0036] 1. Weigh sodium citrate (Na 3 C 6 h 5 o 2 )29.0g and ammonium sulfate ((NH 4 ) 2 SO 4 ) 58.0g was added into a beaker, and dissolved in 300ml of distilled water to obtain a solution;

[0037] 2. Weigh nickel sulfate (NiSO 4 ·6H 2 O) 5.0g, cobalt sulfate (CoSO 4 ·6H 2 O) 25.0g, sodium tungstate (Na 2 WO 4 ) 0.8g was added to the beaker in turn, and dissolved in 400ml of distilled water to obtain a solution;

[0038] 3. Add the solution obtained in step 2 into the solution obtained in step 1 under stirring to obtain a mixed solution;

[0039] 4. Weigh sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 19.0g was added into a beaker, and dissolved in 200ml of distilled water to obtain a solution;

[0040] 5. Slowly add the solution obtained in step 4 into the mixed solution obtained in step 3 under stirring to obtain a mixed solution;

[0041] 6. Adjust the pH value of the mix...

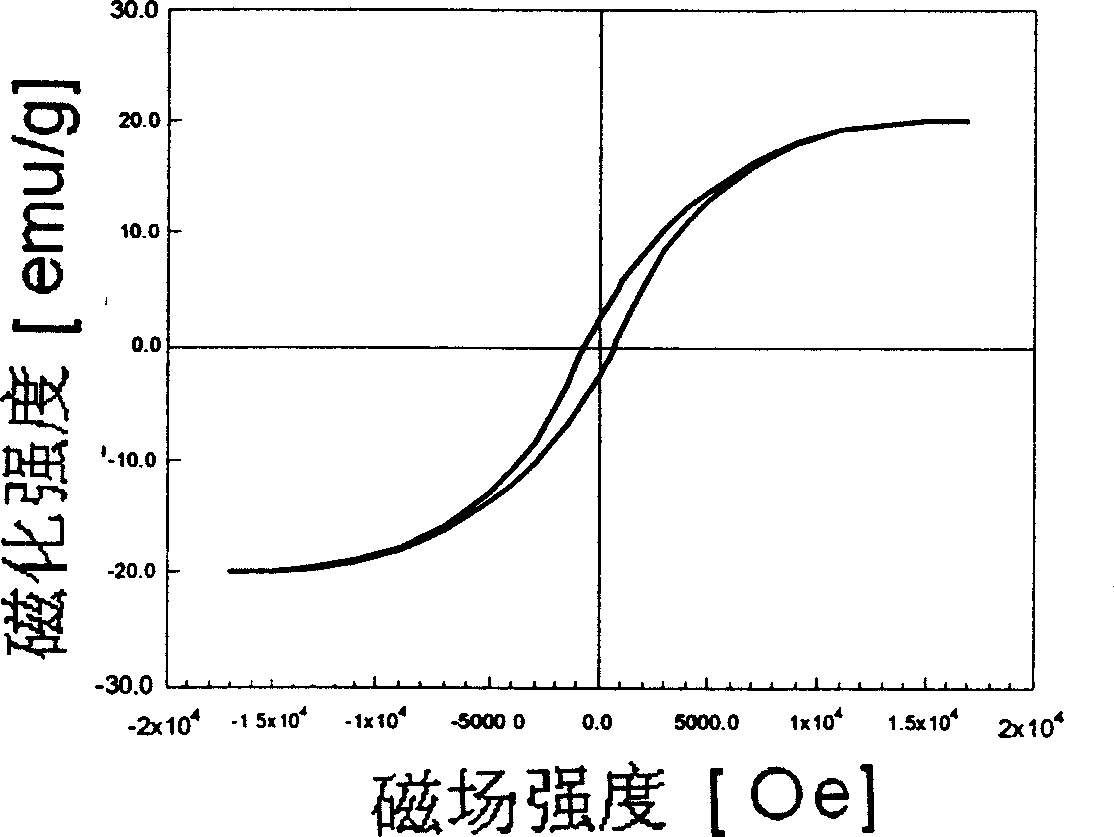

Embodiment 3

[0043] The preparation of No. 3 electroless plating solution, its preparation steps are:

[0044] 1. Weigh sodium citrate (Na 3 C 6 h 5 o 2 )36.0g and ammonium sulfate ((NH 4 ) 2 SO 4 ) 70.0g was added into a beaker, and dissolved in 300ml of distilled water to obtain a solution;

[0045] 2. Weigh nickel sulfate (NiSO 4 ·6H 2 O) 13.0g, cobalt sulfate (CoSO 4 ·6H 2 O) 30.0g, sodium tungstate (Na 2 WO 4 ) 3.3g was added to the beaker in turn, and dissolved in 400ml of distilled water to obtain a solution;

[0046] 3. Add the solution obtained in step 2 into the solution obtained in step 1 under stirring to obtain a mixed solution;

[0047] 4. Weigh sodium hypophosphite (NaH 2 PO 2 ·H 2 O) 25.0g is added in a beaker, and dissolved in 200ml of distilled water to obtain a solution;

[0048] 5. Slowly add the solution obtained in step 4 into the mixed solution obtained in step 3 under stirring to obtain a mixed solution;

[0049] 6. Adjust the pH value of the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com