Production process of biological-organic-inorganic ternary compound fertilizer

A bio-organic-inorganic, production process technology, applied in the direction of bio-organic part treatment, organic fertilizer, organic fertilizer preparation, etc., can solve the problems of less water evaporation, inactivation and death of functional bacteria, low fermentation temperature cannot kill roundworm eggs, etc. , to achieve the effect of less sour and odorous gas generation, ensure the quantity and activity, and shorten the decomposition cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

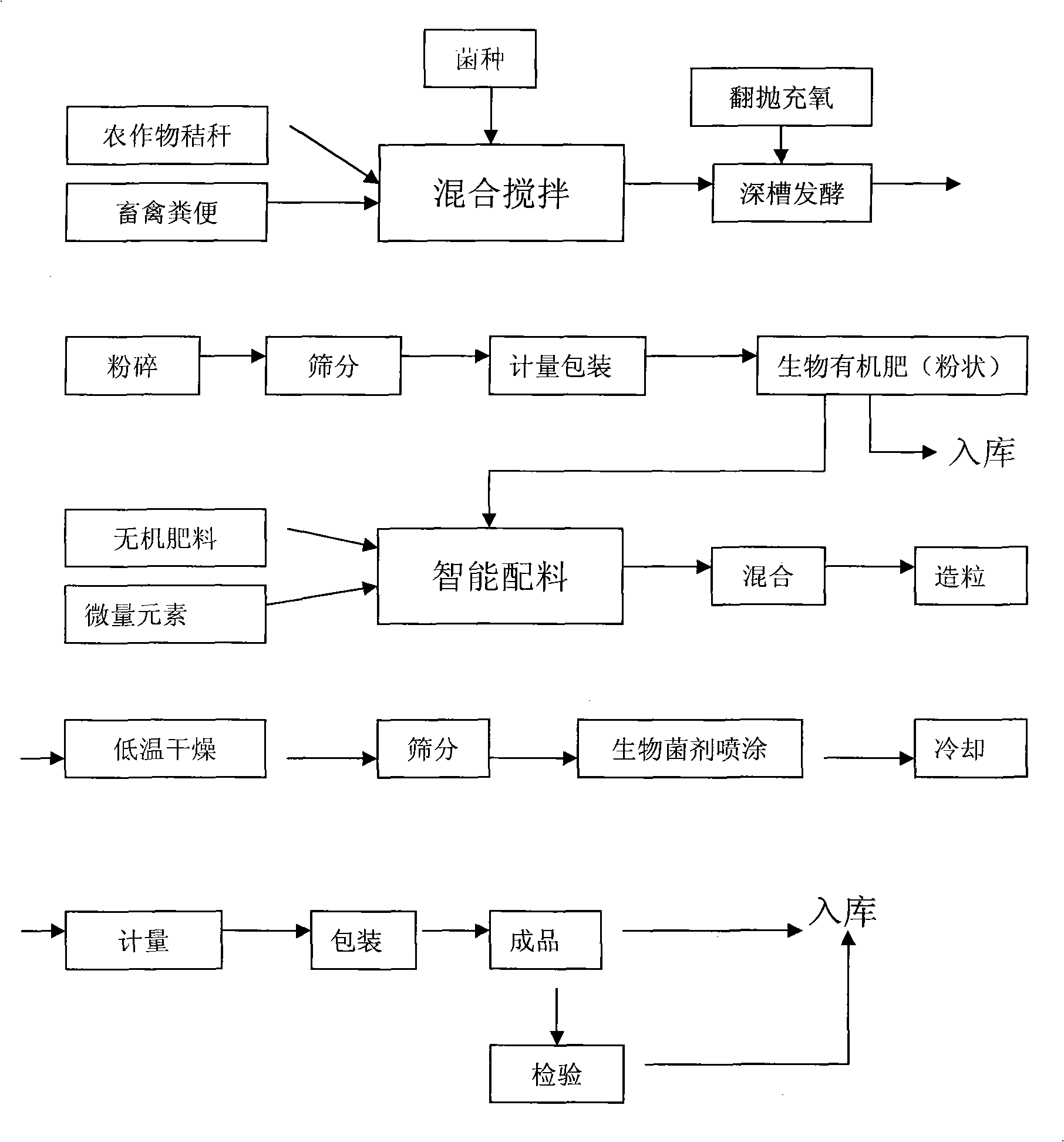

[0022] Accompanying drawing is the production process flowchart of the present invention.

[0023] The present invention will be further described below through specific embodiments.

[0024] The production process of making bio-organic-inorganic ternary compound fertilizer by using livestock and poultry manure and crop straw organic matter, biological bacteria agent and inorganic fertilizer, the specific steps are as follows:

[0025] ① Mixing material: use the intelligent batching and mixing machine to mix and stir the organic components of crop straw, livestock and poultry manure and active biological bacteria according to the specified ratio, and determine the addition ratio according to the organic matter content and water content of crop straw and livestock and poultry manure. Control and adjust the carbon-nitrogen ratio and PH value, adjust the carbon-nitrogen ratio of the material to 26-35, and the pH to 5.5-8.5, strictly control the fermentation moisture, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com