Cellulose-degrading biocontrol bacillus and application and preparation thereof

A technology for degrading cellulose and Bacillus, applied in the field of microorganisms, can solve the problem of inseparable from high-efficiency cellulose-degrading strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

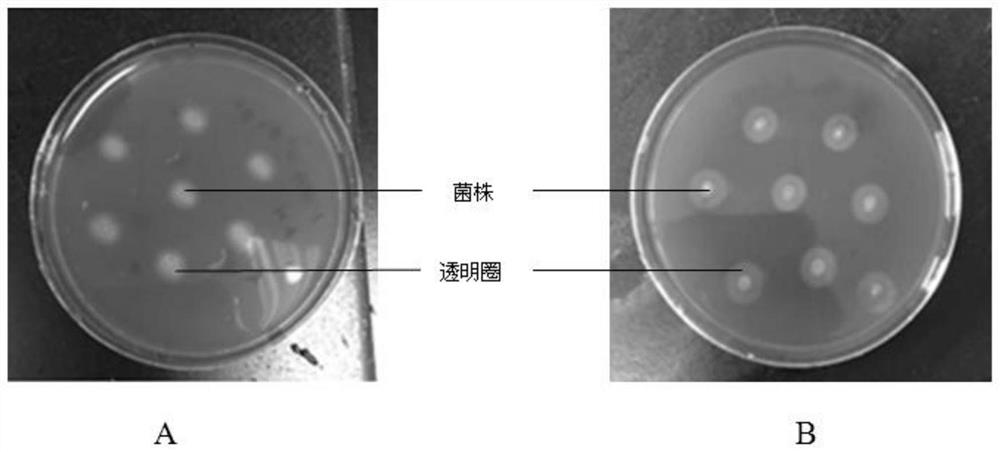

[0021] Isolation and Screening of Cellulose Degrading Bacteria

[0022] 1. Source of soil samples

[0023] Fresh soil samples were taken from the straw returning soil of Caoxinzhuang Experimental Farm of Northwest Agriculture and Forestry University in Yangling District, Shaanxi Province. Appropriate amount of water, for a period of one week of cultivation, until the microorganisms in the soil recover. After the microorganisms in the soil recovered, wheat and corn stalks were added to the tissue culture bottle at 28°C for enrichment culture for 50 days. Soil samples were collected on days 1, 14, and 40 to isolate cellulose-degrading bacteria.

[0024] 2. Culture medium formula

[0025] (1) Enrichment medium: 5 g of cellulose (straw), 5 g of peptone, 5 g of sodium chloride, 0.5 g of dipotassium hydrogen phosphate, 0.5 g of magnesium sulfate, and 1000 ml of distilled water. Sterilize at 121°C for 2h.

[0026] (2) Screening and identification medium: sodium carboxymethylcellu...

Embodiment 2

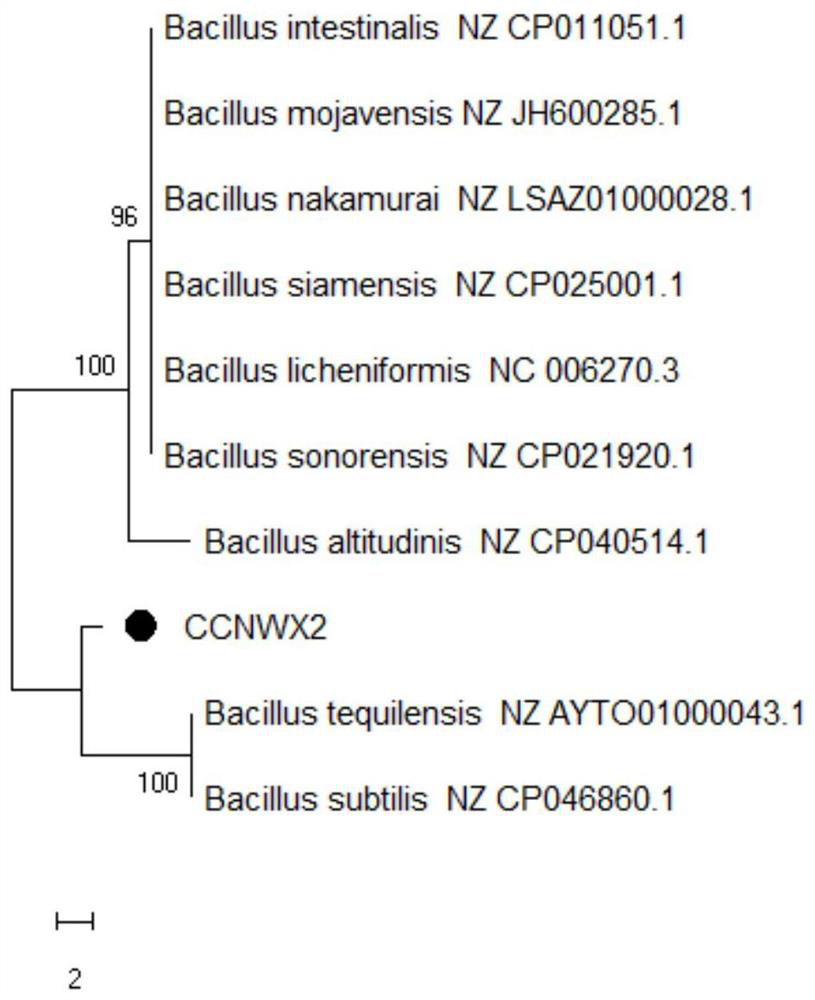

[0035] Identification of Cellulose Degrading Strains

[0036] After cultivating the strain in a shaker at 140rpm in liquid medium for 2 days, extract the DNA and perform 16s rDNA sequencing. The sequence results are as follows:

[0037]CTCAGTACCCTATTCCTGAGATGATTCTTGAGGAGTCCACCAAAAACTTGCTCCCTGATGTTAGCGGCGG ACGGGTGAGTAACACGTGGGTAACCTGCCTGTAAGACTGGGATAACTCCGGGAAACCGGGGCTAATACCGGATGG TTGTTTGAACCGCATGGTTCAAACATAAAAGGTGGCTTCGGCTACCACTTACAGATGGACCCGCGGCGCATTAGC TAGTTGGTGAGGTAACGGCTCACCAAGGCAACGATGCGTAGCCGACCTGAGAGGGTGATCGGCCACACTGGGACT GAGACACGGCCCAGACTCCTACGGGAGGCAGCAGTAGGGAATCTTCCGCAATGGACGAAAGTCTGACGGAGCAAC GCCGCGTGAGTGATGAAGGTTTTCGGATCGTAAAGCTCTGTTGTTAGGGAAGAACAAGTACCGTTCGAATAGGGC GGTACCTTGACGGTACCTAACCAGAAAGCCACGGCTAACTACGTGCCAGCAGCCGCGGTAATACGTAGGTGGCAA GCGTTGTCCGGAATTATTGGGCGTAAAGGGCTCGCAGGCGGTTTCTTAAGTCTGATGTGAAAGCCCCCGGCTCAA CCGGGGAGGGTCATTGGAAACTGGGGAACTTGAGTGCAGAAGAGGAGAGTGGAATTCCACGTGTAGCGGTGAAAT GCGTAGAGATGTGGAGGAACACCAGTGGCGAAGGCGACTCTCTGGTCTGTAACTGACGCTGAGGAGCGAAAGCGT GG...

Embodiment 3

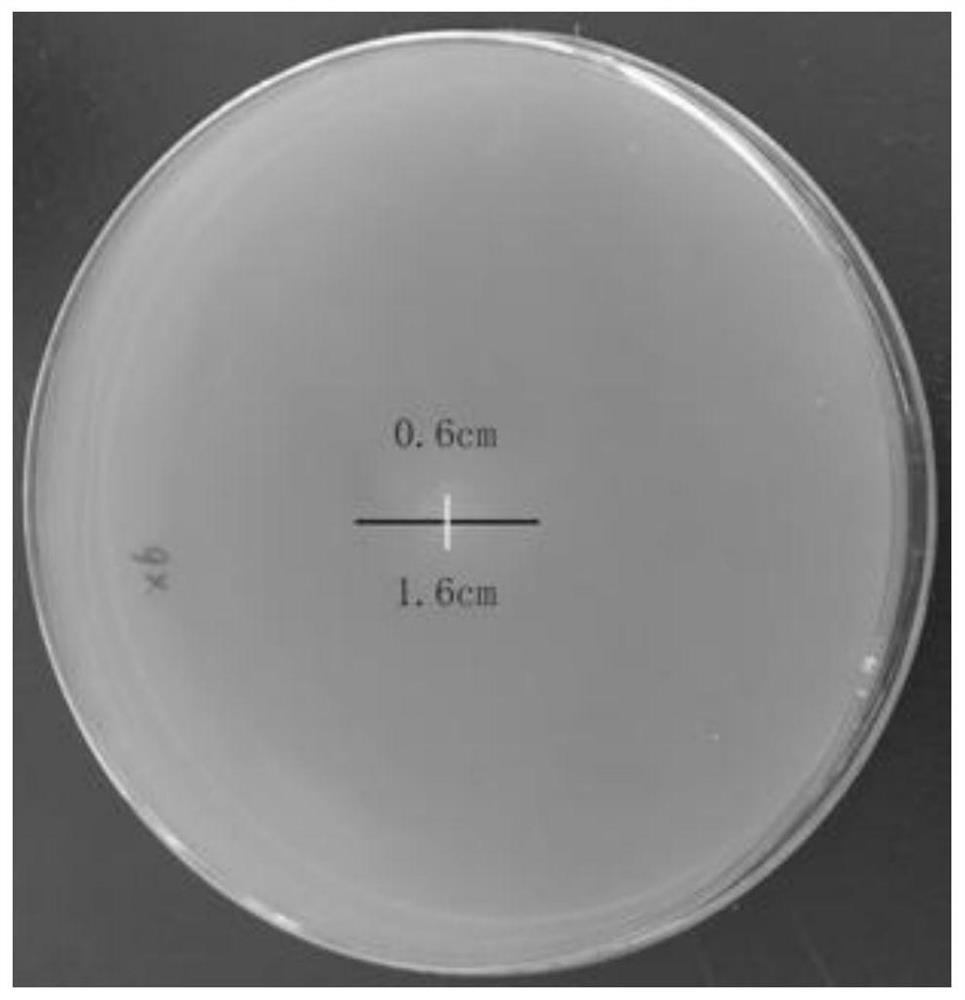

[0041] Determination of cellulase activity

[0042] 1. Drawing of glucose standard curve

[0043] Add 1mg / mL standard glucose solution 0mL, 0.2mL, 0.4mL, 0.6mL, 0.8mL, 1mL to each of 3 tubes (3 repetitions) in 18 15ml tubes, and make up to 100mL with distilled water. 1.5ml, add 1.5mL DNS solution, shake well, place in boiling water bath and continue to heat for 10min, take it out and cool immediately, make up to 15mL accurately with distilled water, shake well, measure its absorbance at 540nm wavelength, take glucose content (mg / m L) is the abscissa, and the corresponding absorbance is the ordinate, and the glucose standard curve is drawn as Figure 4 .

[0044] 2. Determination of cellulase activity

[0045] After the crude enzyme solution is centrifuged at 12000r / min, take 0.5mL of the supernatant and add it to a stoppered colorimetric tube that has been dried to constant weight in advance, and accurately add 1mL of 1% carboxymethylcellulose sodium solution, and add Boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com