Method for producing organic fertilizer using microbe bacteria to quick fer menting pig's feces

A technology of microbial inoculum and commercial organic fertilizer, which is applied in the preparation of organic fertilizer, biological organic part treatment, organic fertilizer and other directions, can solve problems such as unfavorable factory-scale processing and utilization, unfavorable popularization and application, incomplete decomposition, etc. To achieve the effect of convenient factory production and large-scale popularization and application, uniform appearance, and less odorous gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

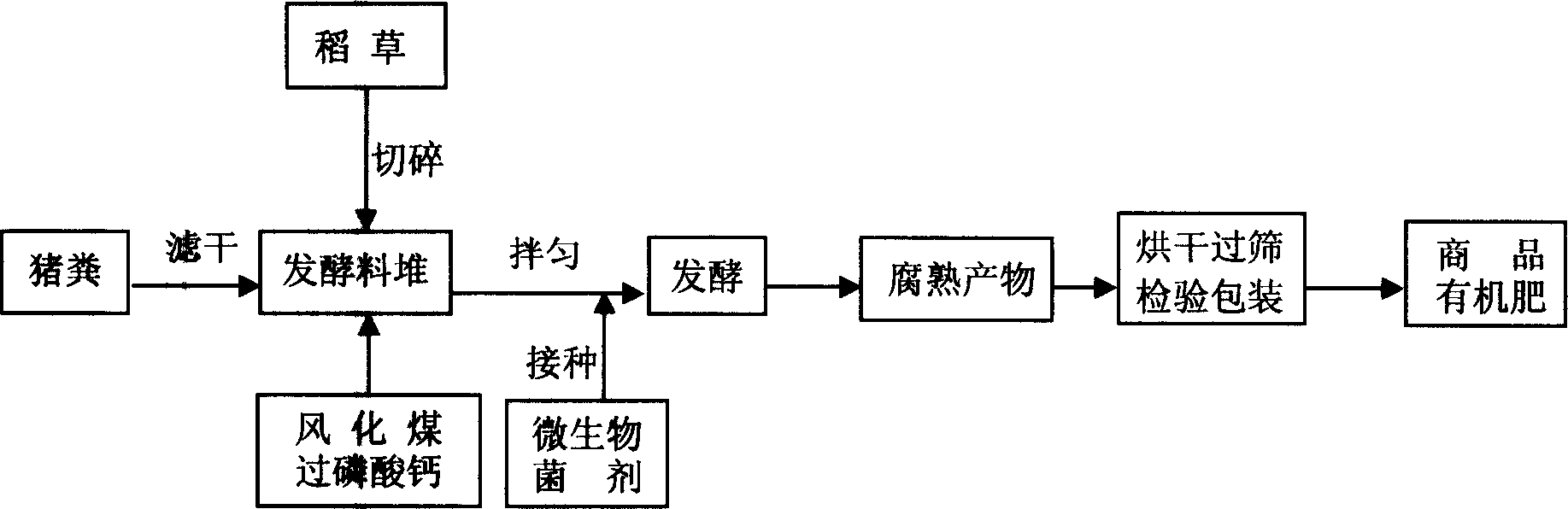

Image

Examples

Embodiment Construction

[0015] Preliminarily filter the pig manure, cut the straw into 2-3cm long, calculate the appropriate ratio of various raw materials according to the C / N ratio of various raw materials and the optimum C / N ratio for fermentation (this scheme is 60% of solid pig manure, Straw (2-3cm) 25%, weathered coal 10%, superphosphate 5%), add various ingredients in proportion, mix well, adjust the water content of the stockpile to keep it within the range of 57%-62% , then inoculate the microbial agent, pile up and ferment, and start turning the pile for the first time when the temperature reaches above 50°C. With the proliferation of microorganisms, the pile will continue to maintain high temperature. When the temperature of the pile exceeds 70°C, turn over the pile in time to aerate and cool down. Generally, it is enough to turn the pile once every 2-3 days. After the high temperature lasts for 5-7 days, the temperature of the pile begins to drop. The pile is basically decomposed, turn it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com