A kind of admixture for magnesium phosphate cement repair mortar and preparation method thereof

A technology of magnesium phosphate cement and repair mortar, which is applied in the field of building materials, can solve the problems of limited water resistance of magnesium phosphate cement, and achieve the effects of compensating for the reduction in strength, improving thermal insulation, and reducing porosity in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 is an admixture for a magnesium phosphate cement repair mortar disclosed by the present invention and a preparation method thereof, the amount of the admixture is 25% of the total amount of the magnesium phosphate cement repair mortar, and the admixture includes the following components by weight :

[0039] components parts by weight Iron Vanadium 5 Silica fume 17.5 sodium pyrophosphate 7.5 Sodium lignosulfonate 2 citric acid 2 slag 30.05 fly ash 24.95 rice husk ash 3.5

[0040] A preparation method for an admixture for magnesium phosphate cement repair mortar, specifically comprising the following steps:

[0041] S1. Mixing of water resistant agent: first stir and mix iron vanadium, silica fume and sodium pyrophosphate evenly, the stirring speed is 25r / min, and the stirring temperature is 25°C;

[0042] S2. Auxiliary mixing: Then add slag, fly ash, rice husk ash, sodium lignosulfonate and cit...

Embodiment 2

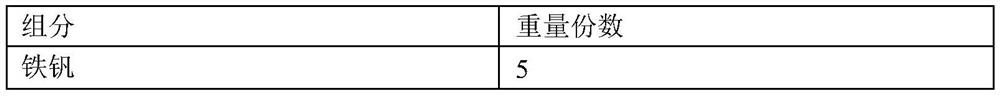

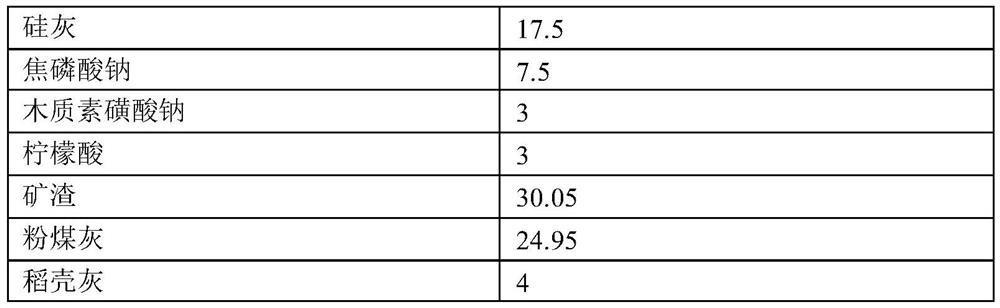

[0043]Embodiment 2 is an admixture for a magnesium phosphate cement repair mortar disclosed by the present invention and a preparation method thereof, the amount of the admixture is 25% of the total amount of the magnesium phosphate cement repair mortar, and the admixture includes the following components by weight :

[0044]

[0045]

[0046] The preparation method of the admixture for repairing mortar with magnesium phosphate cement, the specific steps are the same as in Example 1.

Embodiment 3

[0047] Embodiment 3 is an admixture for a magnesium phosphate cement repair mortar disclosed by the present invention and a preparation method thereof, the amount of the admixture is 25% of the total amount of the magnesium phosphate cement repair mortar, and the admixture includes the following components by weight :

[0048] components parts by weight Iron Vanadium 5 Silica fume 17.5 sodium pyrophosphate 7.5 Sodium lignosulfonate 1 citric acid 1 slag 30.05 fly ash 24.95 rice husk ash 3

[0049] The preparation method of the admixture for repairing mortar with magnesium phosphate cement, the specific steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com