A kind of high damping concrete and preparation method thereof

A concrete and high damping technology, which is applied in the field of building materials, can solve the problems of concrete compressive strength and damping ratio, and achieve the effects of low price, promoting hydration process, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

Embodiment

Evenly dispersed in the middle, no obvious clustering phenomenon;

3) add weighed rubber powder, microsilica powder successively, stir 2~3min;

4) add weighed natural river sand, gravel successively, stir 2~3min;

5) add weighed water and water reducing agent successively, continue to stir 3min, obtain concrete mixture;

6) load the obtained concrete mixture into the mould that has been painted with release agent, place the mould on a vibrating table

After the vibration is completed, scrape off the excess concrete on the surface of the mold and smooth the surface;

[0046] 7) Finally, put all the test pieces into the standard curing room for curing for 28d, and then the high damping fiber reinforced concrete can be obtained.

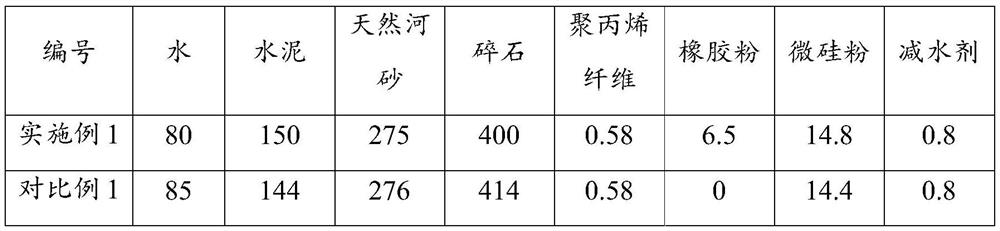

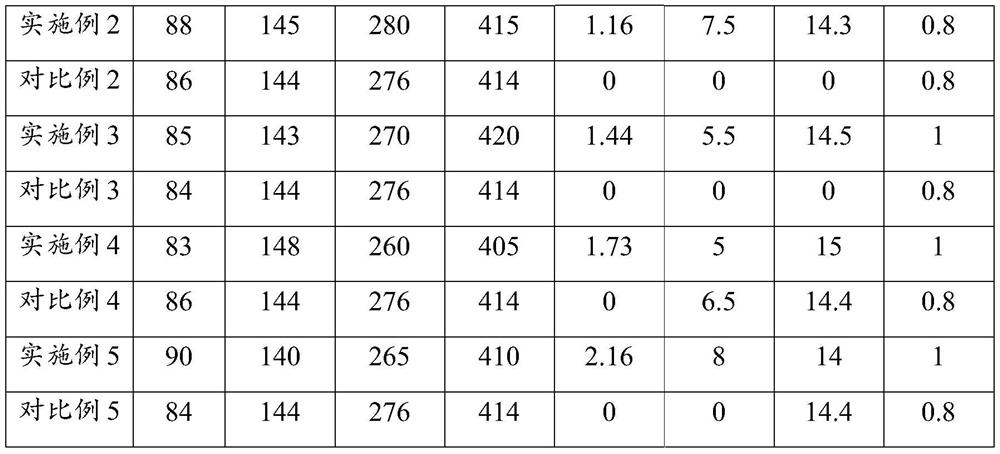

The present invention has designed the proportioning of five groups of embodiments altogether, and concrete proportioning is shown in Table 1.

The present invention has also designed five groups of comparative examples, and comparative examples adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com