Low-carbon X80 pipeline steel plate roll and manufacturing method thereof

A steel coil and pipeline technology, applied in the field of micro-alloyed steel manufacturing, can solve the problems of insufficient low-temperature toughness, low strength, and inability to manufacture submerged arc welded pipes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

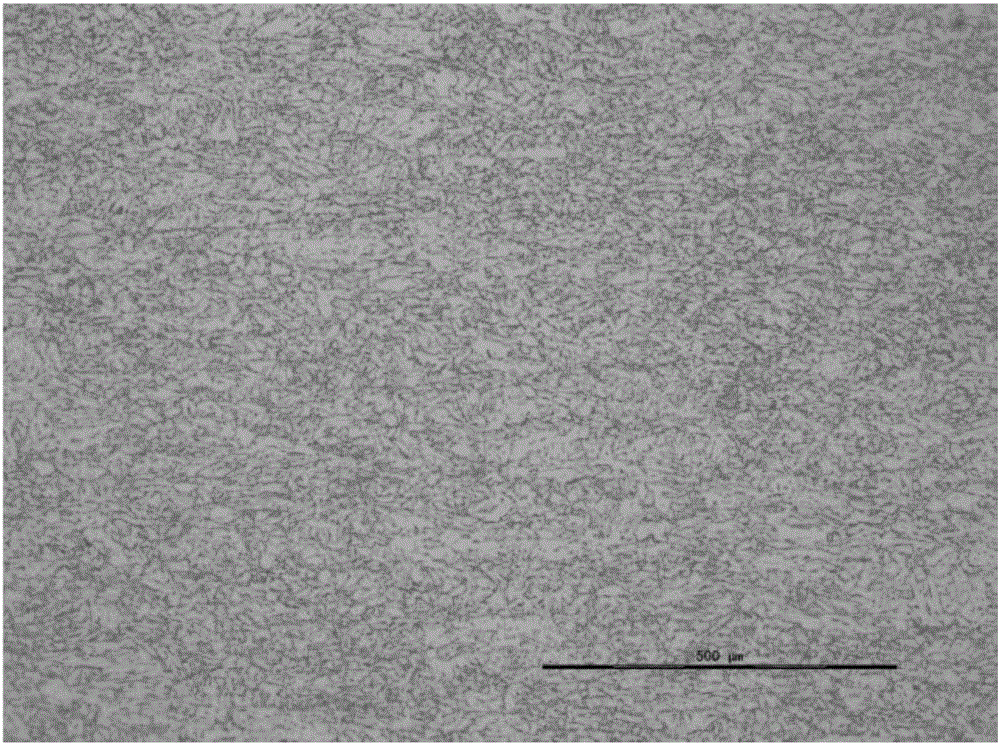

Image

Examples

Embodiment X80

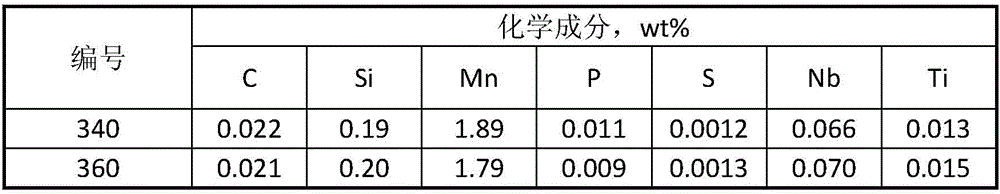

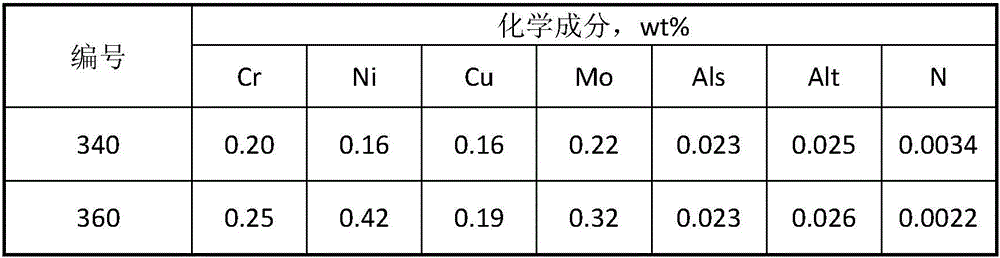

[0041] Continued table 1 embodiment X80M smelting and finished product chemical composition

[0042]

[0043] Table 2 The TMCP process system of the X80M pipeline steel of the embodiment

[0044]

[0045] The sampling position for the tensile test of the coil is the position corresponding to the transverse direction of the steel pipe (30° in the rolling direction). Tensile specimens are plate-shaped specimens with rectangular cross-sections.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com