Nylon 6 composition with excellent wear resistance and preparation method of nylon 6 composition

A technology of wear resistance and composition, which is applied in the field of nylon 6 composition and its preparation, can solve the problems of lowering the mechanical properties of matrix resin and high addition of wear-resistant agent, and achieve excellent wear-resistant effect, good wear-resistant effect, and stable mixing moderate speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

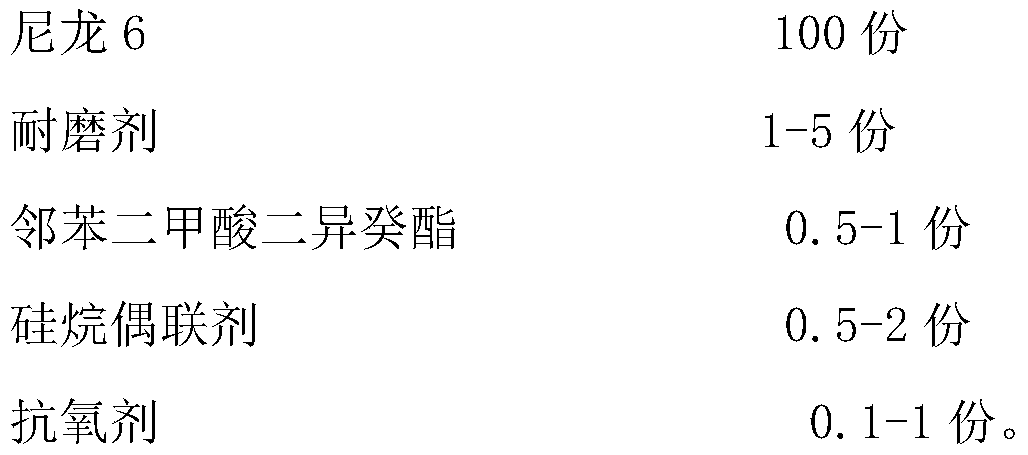

Method used

Image

Examples

Embodiment 1

[0041] The anti-wear agent used is a compound of wollastonite and alumina in a weight ratio of 1:4. The aspect ratio of wollastonite is 20:

[0042] 1. The average particle diameter is 5 μm; the average particle diameter of alumina is 3 μm.

[0043] Add 6100 parts of nylon, 2.5 parts of anti-wear agent, 1 part of silane coupling agent, and 0.6 part of antioxidant into the mixer at room temperature and low speed and stir for 38 seconds. After mixing evenly, add it to the twin-screw extruder; After being granulated, a nylon 6 composition with excellent wear resistance is obtained.

[0044] The low-speed stirring speed of the mixer is 100 rpm; the temperature of the first zone of the twin-screw extruder is 180°C, the temperature of the second zone is 220°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 250°C, the temperature in the sixth zone is 260°C; the speed of the twin-screw main engine is ...

Embodiment 2

[0077] The anti-wear agent used is a compound of wollastonite and alumina in a weight ratio of 1:4. The aspect ratio of wollastonite is 20:

[0078] 1. The average particle diameter is 5 μm; the average particle diameter of alumina is 3 μm.

[0079] Add 100 parts of nylon 6, 5 parts of anti-wear agent, 1.5 parts of silane coupling agent, and 1 part of antioxidant into the mixer at room temperature and low speed and stir for 40 seconds. After mixing evenly, add it to the twin-screw extruder; Granulating after extrusion to prepare a nylon 6 composition with excellent wear resistance.

[0080] The low-speed stirring speed of the mixer is 120 rpm; the temperature of the first zone of the twin-screw extruder is 200°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 250°C, and the temperature of the fifth zone is 260°C, the temperature in the sixth zone is 260°C; the speed of the twin-screw main engine ...

Embodiment 3

[0082] The aspect ratio of wollastonite used is 20:1, the average particle diameter is 5 μm; the average particle diameter of alumina is 3 μm.

[0083] Anti-wear agent treatment method: compound wollastonite and alumina at a weight ratio of 1:4, then put it into stearic acid ethanol solution, and obtain it after ultrasonic reflux at 40°C for 1.5 hours and then dry; the weight of stearic acid and ethanol The ratio is 1:9.

[0084] Add 100 parts of nylon 6, 5 parts of anti-wear agent, 1.5 parts of silane coupling agent, and 1 part of antioxidant into the mixer at room temperature and low speed and stir for 40 seconds. After mixing evenly, add it to the twin-screw extruder; Granulating after extrusion to prepare a nylon 6 composition with excellent wear resistance.

[0085] The low-speed stirring speed of the mixer is 120 rpm; the temperature of the first zone of the twin-screw extruder is 200°C, the temperature of the second zone is 230°C, the temperature of the third zone is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com