Low-cost high-strength steel plate for shipbuilding and manufacturing method thereof

A high-strength, low-cost technology, applied in the manufacture of tools, metal rolling, metal rolling, etc., can solve the problems of cost pressure, rising raw material prices, and increased production costs of high-strength shipbuilding steel, so as to reduce production costs, Effect of improving low-temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

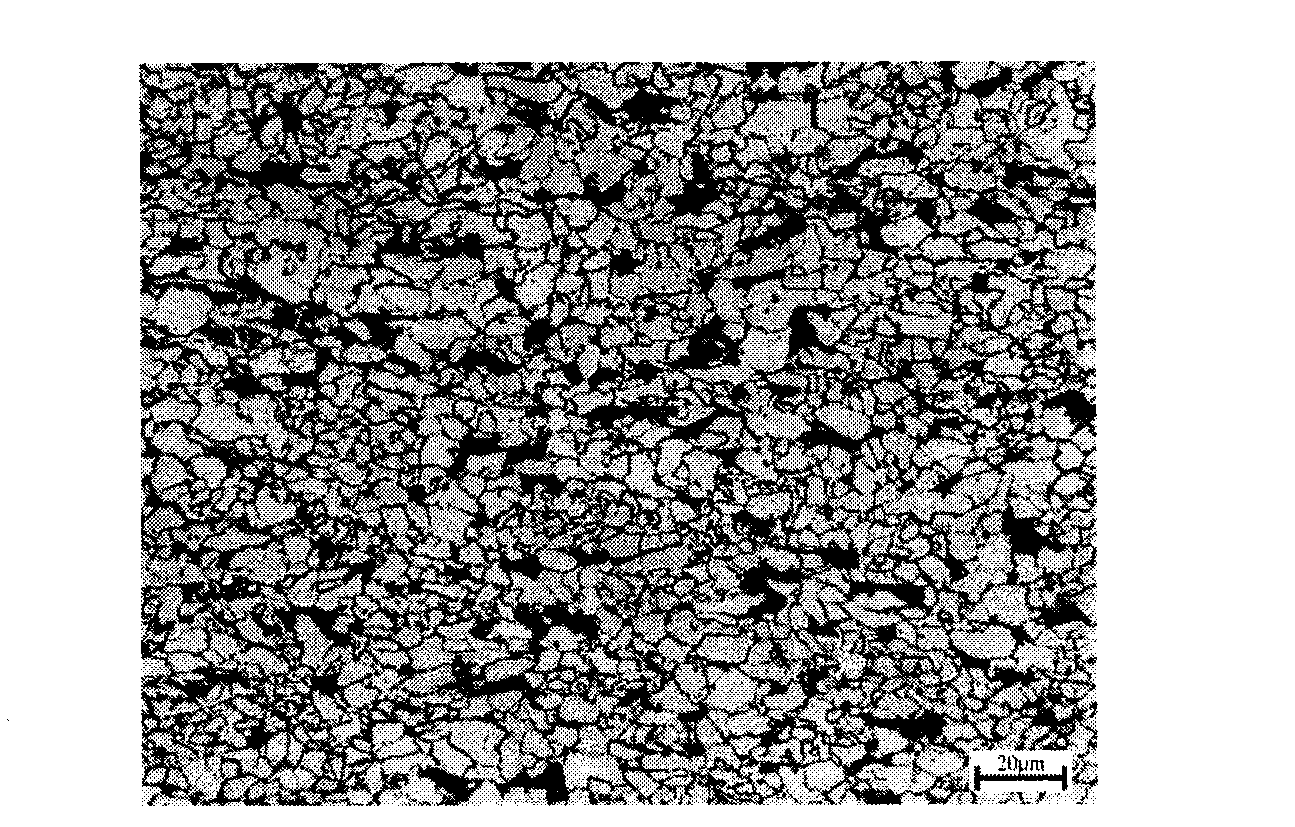

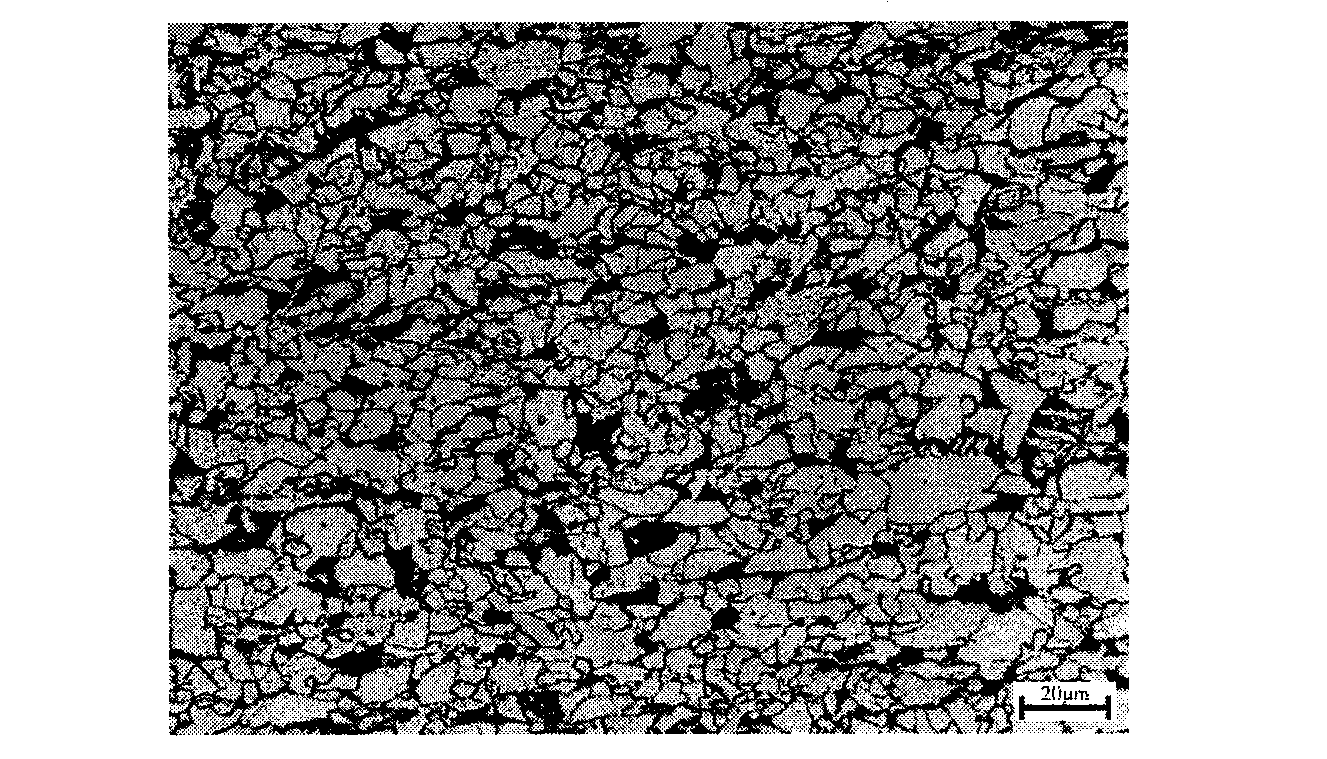

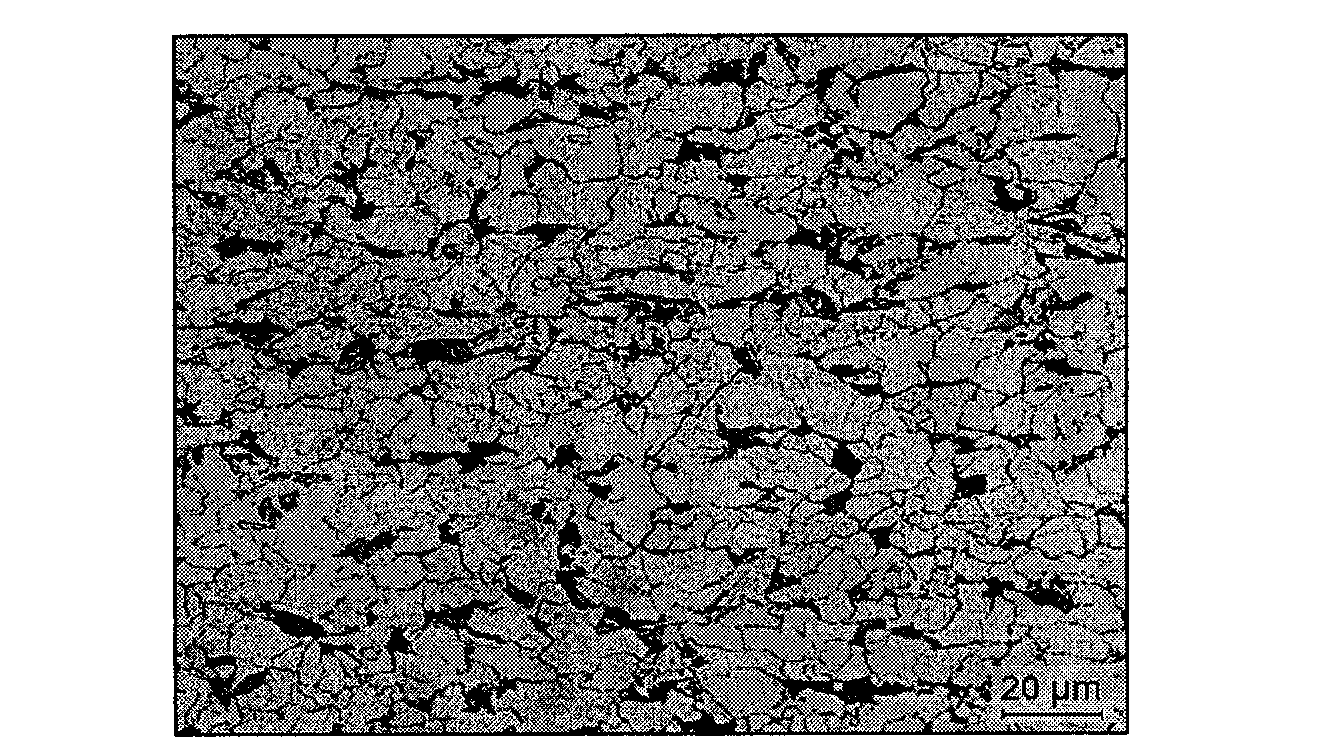

Image

Examples

Embodiment Construction

[0016] Below by embodiment the present invention will be further described.

[0017] Table 1 is the embodiment of the present invention, and the chemical composition, main rolling and cooling parameters and mechanical properties of the embodiment and comparative examples are given in the table. The first eight in Table 1 are examples of applying the technology of the present invention to produce low-cost high-strength steel plates for shipbuilding. The latter four are comparative examples, and the main rolling parameters and mechanical properties of the existing steel plates containing Nb, V, Ti, and Al grain refinement elements are given. Comparative examples 1 and 2 do not use water cooling, the latter is continuous rolling without two-stage controlled rolling; comparative example 3 adopts ultra-fast cooling, and comparative example 4 adopts ACC layer cooling.

[0018] Table 1 Composition, process and performance of the steel of the embodiment of the present invention

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com