Ultra-thick hot-rolled H-shaped steel with low ductile-brittle transition temperature and production method thereof

A technology of ductile-brittle transition temperature and production method, which is applied in the field of iron and steel, and can solve problems such as the difficulty in realizing the full-protection continuous casting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

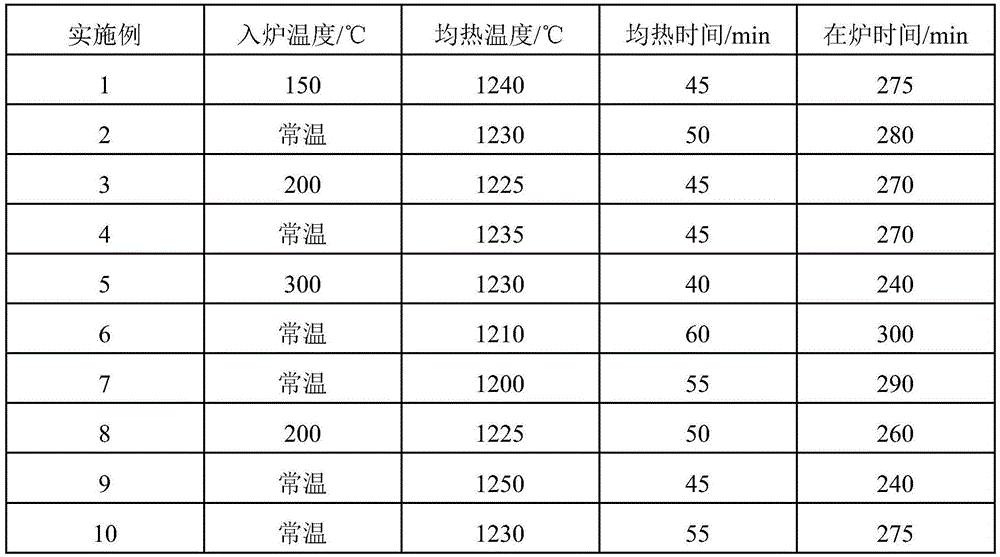

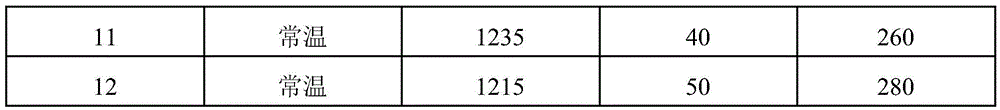

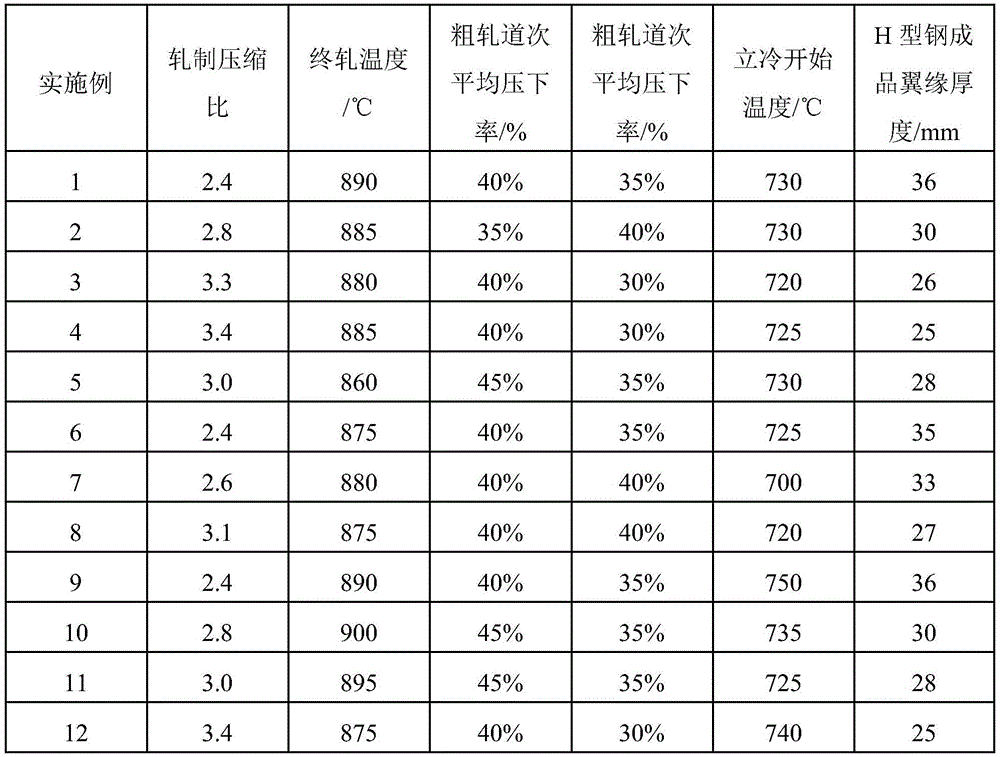

Examples

Embodiment Construction

[0021] The present invention will be described in detail through specific embodiments below.

[0022] The hot-rolled H-shaped steel with extra thickness and low ductile-brittle transition temperature of the present invention, its chemical composition includes: C0.08%-0.15%, Si0.10%-0.40%, Mn1.0%-1.5%, P ≤0.015%, S≤0.008%, V0.020%~0.070%, Ti0.005%~0.025%, N0.006%~0.015%, Ni0.10%~0.50%, the rest is iron and residual trace impurities.

[0023] The manufacture method of the hot-rolled H-shaped steel provided by the invention is specifically as follows:

[0024] The molten iron, scrap steel or the mixture of molten iron and scrap steel is smelted by a top-bottom combined blowing converter, and the steel is tapped. When tapping reaches 3 / 4, vanadium-nitrogen alloy, vanadium-iron alloy and nickel plate are added to the molten steel to remove V in the molten steel. Adjust to 0.020~0.070wt% of the total weight of molten steel;

[0025]After the converter is tapped, enter LF refining....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com