Low temperature resistance stained glass fiber reinforcement nylon 6 and preparation method thereof

A glass fiber, low temperature resistant technology, applied in the field of low temperature resistant colored glass fiber reinforced nylon 6 material, can solve the problems of material performance decline, uneven color dispersion, glass fiber, etc., and achieve good performance, uniform distribution and bright color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

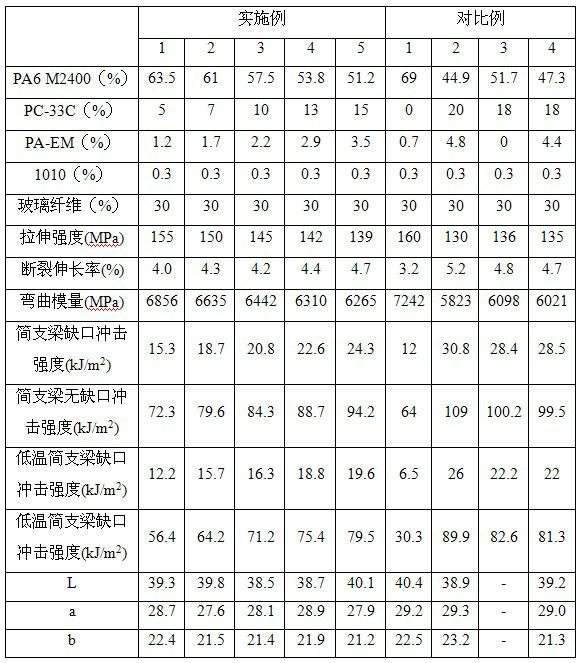

Examples

preparation example Construction

[0036] The preparation method of the toughening agent is: weigh 72.5kg of POE, 22.5kg of polyethylene, 4.65 kg of maleic anhydride, 0.35 kg of 1,4-bis-tert-butylperoxycumene; After the toric anhydride and peroxide are uniformly mixed in a high-speed mixer, they are blended and extruded by a twin-screw extruder to obtain a toughening agent. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 160°C, the temperature of the second zone is 170°C, the temperature of the third zone is 170°C, the temperature of the fourth zone is 180°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 190°C ℃, the temperature in the seventh zone is 190 ℃, the temperature in the eighth zone is 180 ℃, and the temperature in the ninth zone is 170 ℃; the residence time is 2 minutes, and the speed of the main engine is 240 rpm.

[0037] The preparation method of the composite dye is as follows: take 78.5 kg of PA nylon 6 with a ...

Embodiment 1

[0039] Weigh 63.5kg of PA6 M2400, 5kg of POE, 30kg of glass fiber, 1.2kg of composite dye, and 0.3kg of antioxidant, add it to a high-speed mixer and mix evenly at room temperature. Then, the above mixture is fed into a twin-screw extruder, cooled, dried and pelletized after extrusion. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 250°C, and the temperature of the seventh zone is 245 ℃, the temperature in the eighth zone is 235°C, and the temperature in the ninth zone is 220°C; the residence time is 2 minutes, and the speed of the host is 300 rpm.

Embodiment 2

[0041] Weigh 61kg of PA6 M2400, 7kg of POE, 30kg of glass fiber, 1.7kg of composite dye, and 0.3kg of antioxidant, add them into a high-speed mixer and mix well at room temperature. Then, the above mixture is fed into a twin-screw extruder, cooled, dried and pelletized after extrusion. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 250°C, and the temperature of the seventh zone is 245 ℃, the temperature in the eighth zone is 235°C, and the temperature in the ninth zone is 220°C; the residence time is 2 minutes, and the speed of the host is 300 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com