Boron-modified H-shape steel having well low-temperature impact flexibility and preparation method thereof

A type of steel, weight percentage technology, applied in the field of H-shaped steel, can solve the problems of increasing inclusion particles, damage to process performance and service performance, inclusion cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

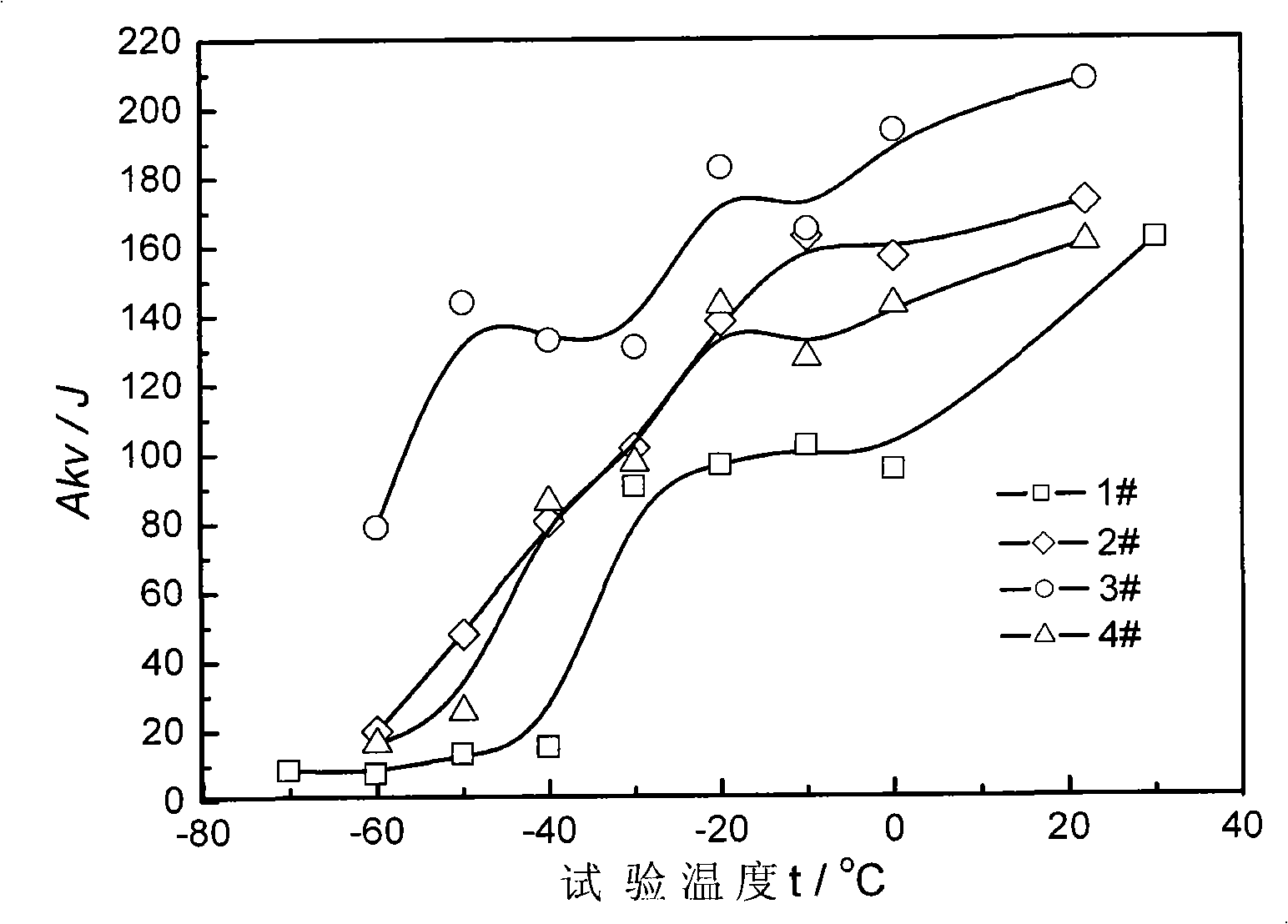

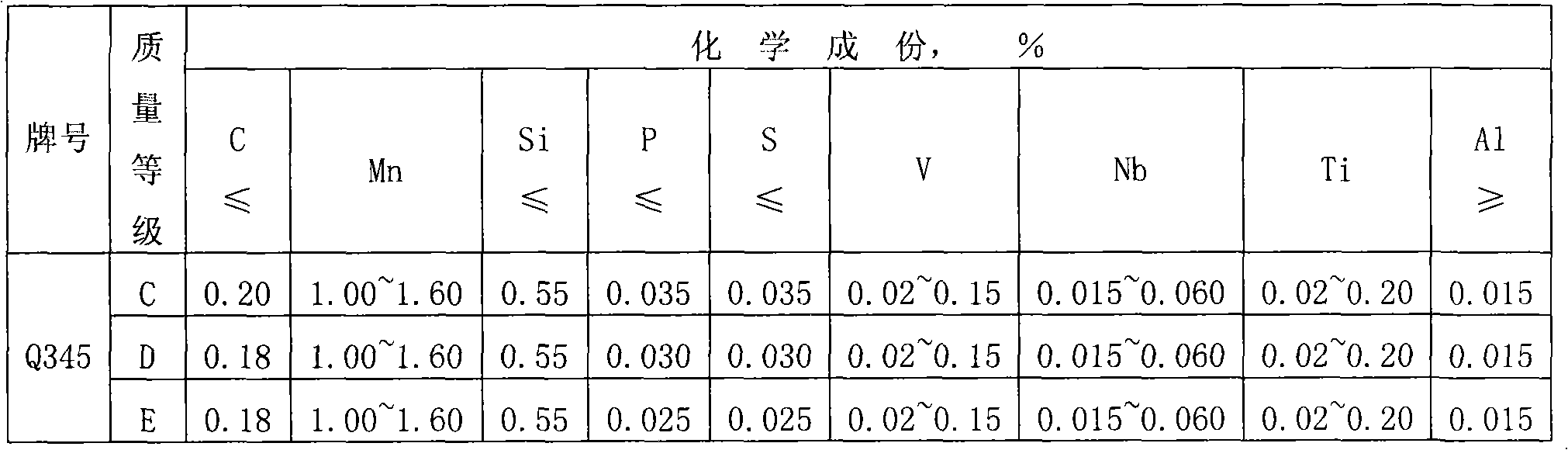

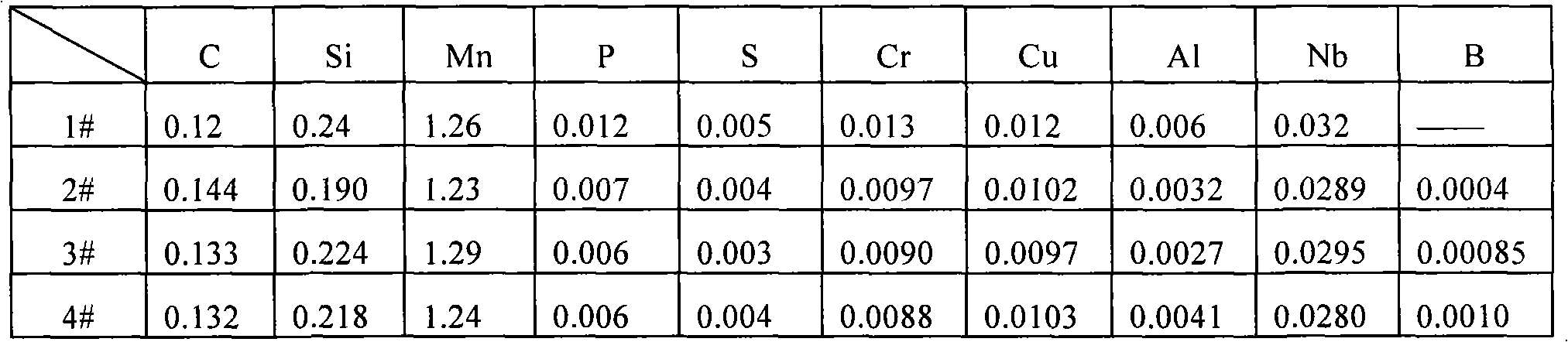

[0018] Based on the Q345H-shaped steel that does not require special heat treatment, and in consideration of the actual steelmaking control ability and product quality, by adding boron and optimizing the steel composition, the invention obtains an H-shaped steel with good low-temperature impact toughness. The technical scheme is as follows:

[0019] A boron-added Q345H section steel with good low-temperature impact toughness, the weight percentage of the steel composition is as follows (%):

[0020] C 0.08~0.20, Mn 1.00~1.60, Si 0.10~0.55, P≤0.025, S≤0.025, Nb 0.015~0.035, B 0.0005~0.0012, and the balance is Fe and trace impurities.

[0021] Preferably, a kind of boron-added Q345H type steel, the weight percentage of steel composition is as follows (%):

[0022] C 0.10~0.18, Mn 1.00~1.40, Si 0.10~0.40, P≤0.015, S≤0.015, Nb 0.015~0.030, B 0.0005~0.0010, the balance is Fe and trace impurities.

[0023] Further preferably, a kind of boron-added Q345H type steel, the weight perce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com