Mixed-gas protection high-tenacity carbon steel flux-cored wire

A technology of flux-cored welding wire and mixed gas, which is applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of low low temperature impact performance and insufficient stability, and achieve stable impact performance, stable mechanical performance, and reduce the addition of amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

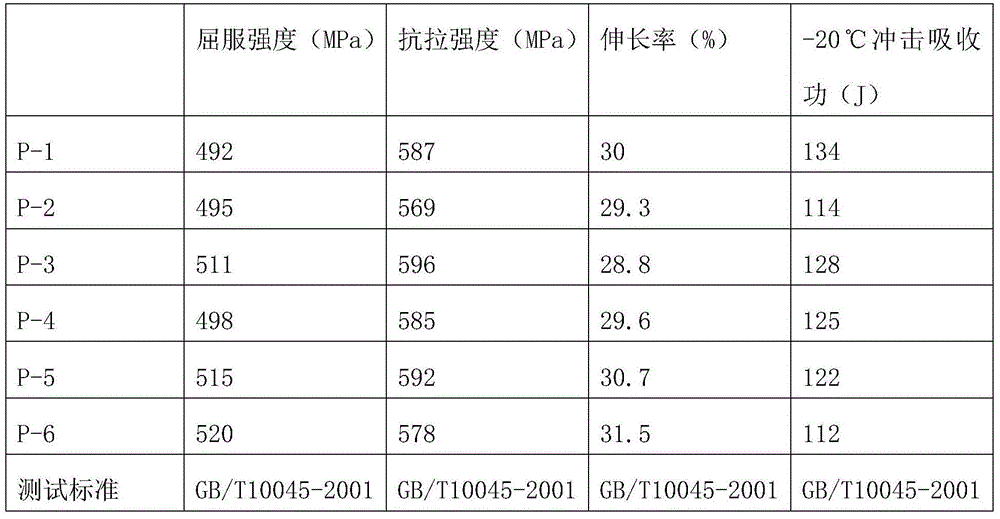

Examples

Embodiment 1

[0020] Select a 10*0.4mm stainless steel strip, first roll it into a U shape, take 33 grams of rutile rutile; 24.5 grams of iron powder; 16.5 grams of silicon manganese alloy; 1.5 grams of low carbon ferromanganese; 3.8 grams of quartz; 3.2 grams of alumina 4.1 grams of zircon sand; 3.4 grams of aluminum fluoride; 5.0 grams of titanium potassium alloy; 5.0 grams of boron powder. Mix the above-mentioned components uniformly and put them into the U-shaped stainless steel tank with a filling rate of 18%. Close the U-shaped tank so that the powder is wrapped in it. Then the final flux-cored welding wire is obtained after drawing and diameter reduction, and the label is P-1.

Embodiment 2

[0022] Select a 10*0.4mm stainless steel strip, first roll it into a U shape, take rutile rutile 48 grams; iron powder 21.5 grams; silicon-manganese alloy 14.8 grams; low-carbon ferromanganese 1.1 grams; quartz 2.2 grams; alumina 3.3 grams 3.5 grams of zircon sand; 3.5 grams of barium fluoride; 3.2 grams of nickel-potassium alloy; 2.1 grams of boron powder. Mix the aforementioned components uniformly and put them into the U-shaped stainless steel belt tank with a filling rate of 20%. Close the U-shaped tank so that the medicine powder is wrapped in it. Then the final flux-cored welding wire is obtained after drawing and diameter reduction, and the label is P-2.

Embodiment 3

[0024] Select a 10*0.4mm stainless steel strip, first roll it into a U shape, take rutile rutile 35 grams; iron powder 23.7 grams; silicon-manganese alloy 15.5 grams; low-carbon ferromanganese 1.5 grams; quartz 4.0 grams; alumina 3.5 grams 3.8 grams of zircon sand; 3.5 grams of calcium fluoride; 4.5 grams of nickel-potassium alloy; 2.5 grams of boron powder and 2.5 grams of niobium powder. Mix the aforementioned components uniformly and put them into the U-shaped stainless steel belt tank with a filling rate of 20%. Close the U-shaped tank so that the medicine powder is wrapped in it. Then the final flux-cored welding wire is obtained after drawing and diameter reduction, and the label is P-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com