Polypropylene composition, polypropylene material, and applications of polypropylene composition and polypropylene material

A polypropylene composition and polypropylene technology, applied in the field of polymers, can solve problems such as insufficient fluidity, inability to use injection molded thin-walled products, and poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

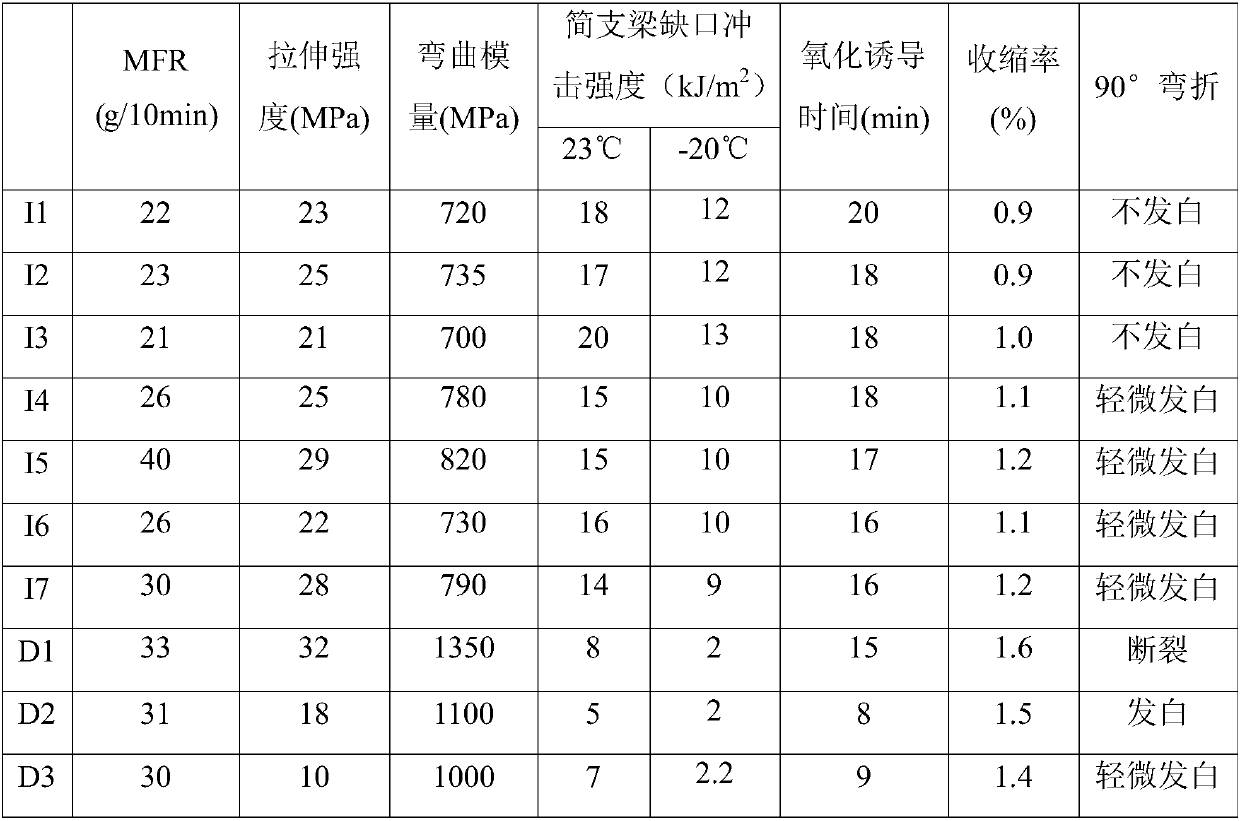

Examples

Embodiment approach

[0033] According to a preferred embodiment of the present invention, the polypropylene composition contains random copolymerized polypropylene, polyolefin elastomer, antioxidant, light stabilizer, slip agent and color masterbatch, wherein, the polypropylene Based on the total weight of the propylene composition, the content of the random copolymerized polypropylene is 64-89% by weight, the content of the polyolefin elastomer is 9-34% by weight, and the content of the antioxidant is 0.2- 1.5% by weight, the content of the light stabilizer can be 0.01-0.5% by weight, the content of the smooth agent is 0.01-3% by weight, the content of the color masterbatch is 1-5% by weight; preferably, Based on the total weight of the polypropylene composition, the content of the random copolymerized polypropylene is 70-85% by weight, the content of the polyolefin elastomer is 10-25% by weight, and the content of the antioxidant The content is 0.3-0.9% by weight, the content of the light stabil...

Embodiment 1

[0043] (1) Based on the total weight of the polypropylene composition, the components and their percentages are:

[0044] Random copolymerization polypropylene resin (at 230 ℃, the melt mass flow rate MFR under the action of 2.16kg load is 30g / 10min, the content of ethylene structural unit is 3% by weight, crystallinity is 80%), 84.95% by weight;

[0045] Polyolefin elastomer (ethylene-butene random copolymer, under 230 ℃, the melt mass flow rate MFR under 2.16kg load is 1.5g / 10min, and the content of butene structural unit is 10% by weight, crystallinity is 18%), 12% by weight;

[0046] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 0.2% by weight;

[0047] Tris(2,4-di-tert-butylphenyl)phosphite, 0.15% by weight;

[0048] The polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol (light stabilizer 622, BASF, Germany, UV366), 0.2% by weight;

[0049] Hydrogenated palm oil glycerides, oleic acid glycerides and polyglycerides...

Embodiment 2

[0054] (1) Based on the total weight of the polypropylene composition, the components and their percentages are:

[0055] Random copolymerization polypropylene resin (at 230 ℃, the melt mass flow rate MFR under the action of 2.16kg load is 35g / 10min, the content of ethylene structural unit is 10% by weight, crystallinity is 78%), 81.70% by weight;

[0056] Polyolefin elastomer (ethylene-butene random copolymer, the melt mass flow rate MFR under 230 ℃, 2.16kg load is 5.0g / 10min, the content of butene structural unit is 8% by weight, crystallinity 15%), 15% by weight;

[0057] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 0.2% by weight;

[0058] Tris(2,4-di-tert-butylphenyl)phosphite, 0.2% by weight;

[0059] Dilauryl thiodipropionate, 0.25 parts by weight;

[0060] Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.25% by weight;

[0061] Oleamide, 0.4% by weight;

[0062] Masterbatch, 2% by weight.

[0063] (2) The preparation method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com