Cross arm for wire pole wiring

A technology of utility poles and cross arms, applied in the direction of building types, layered products, chemical instruments and methods, etc., can solve problems such as inability to meet requirements, increase in ultraviolet rays and temperature, and achieve light weight, simple structure, and improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

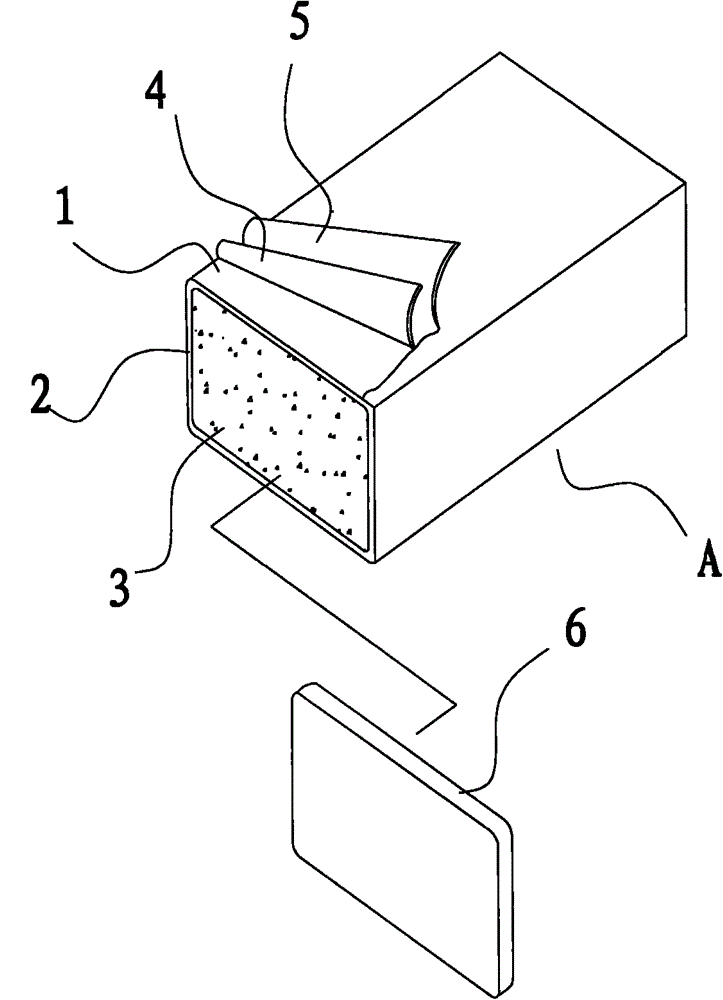

[0012] Such as figure 1 As shown, a cross arm for erecting a utility pole, comprising a cross arm support layer 1, glass fibers 2, a waterproof foamed plastic resistance body 3 filled in the cross arm support layer 1, and a The first anti-ultraviolet layer 4 and the second anti-ultraviolet layer 5 . The glass fiber 2 is continuously wound around the cross-arm support layer 1 to form a square tube. The light weight and high-strength mechanical properties of the glass fiber 2 are used as the main support of the cross-arm support layer 1. The hollow part inside the cross-arm support layer 1 is The filled waterproof foamed plastic resistance body 3 is a waterproof foamed plastic resistance body 3 with the same dielectric coefficient as the glass fiber 2, and the first anti-ultraviolet layer 4 and the second anti-ultraviolet layer 4 coated on the cross-arm suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com