High anti-environmental aging and high temperature resistant polyester resin matrix composite material

A high-temperature-resistant polyester resin technology, applied in the field of polyester resin-based composite materials, can solve the problems of insufficient reinforcement effect, high cost, and insufficient material performance and strength, and achieve high anti-yellowing performance, high dimensional stability, Good anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

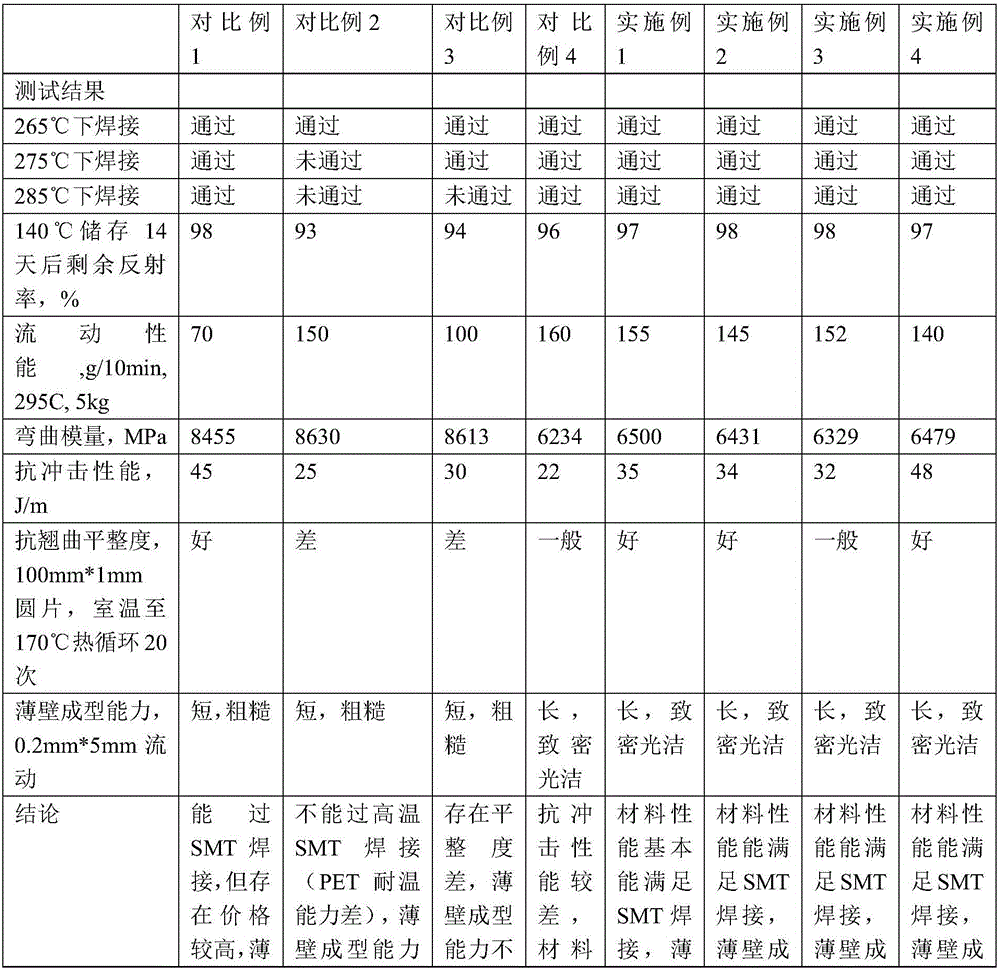

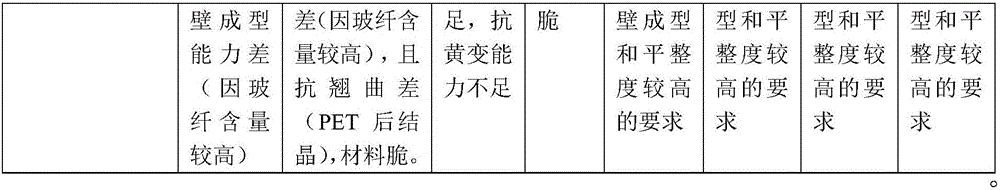

Examples

Embodiment approach

[0029] A polyester resin-based composite material with high resistance to environmental aging and high temperature resistance, which is made by mixing the following raw materials in percentage by weight: thermoplastic resin 30-80%, modified attapulgite powder 0.5-15%, titanium dioxide 5-30 %, antioxidant 0.1-0.5%, release agent 0.2-0.5%, glass fiber 3-10%, mineral powder 5-20%. The thermoplastic resin is composed of poly-1,4-cyclohexanedimethanol terephthalate and polyethylene terephthalate mixed in a mass ratio of 1:1-20:1. The antioxidant is selected from the group consisting of antioxidant 1010, antioxidant 1076, antioxidant 168, antioxidant 1098, antioxidant P-EPQ, antioxidant PEP-36A, antioxidant 300, and antioxidant S One or more of -9299. The release agent is PETs or GSC-9032PC; the mineral powder is talc or light calcium carbonate. The particle size D of the modified attapulgite powder 50 It is 20nm-150nm, and the aspect ratio is 10-50:1; the glass fiber is ultrafine ...

specific Embodiment 1

[0035] A polyester resin-based composite material with high resistance to environmental aging and high temperature resistance. It is made by mixing the following raw materials in weight percentage: PCT 33%, PET 20%, modified attapulgite powder 15%, titanium dioxide 20%, and Oxygen 1010 0.3%, antioxidant 168 0.2%, mold release agent (GSC-9032PC, commercially available) 0.5%, glass fiber (5 microns in diameter) 5%, talc 6%.

specific Embodiment 2

[0036] A polyester resin-based composite material with high resistance to environmental aging and high temperature resistance. It is made by mixing the following raw materials by weight percentage: PCT 33%, PET 20%, modified attapulgite powder 4%, titanium dioxide 20%, and Oxygen agent 1010 0.2%, antioxidant 168 0.3%, release agent (commercially available PETs release agent) 0.5%, glass fiber (5 microns in diameter) 5%, talc 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com