Polycarbonate packaged solar car roof or skylight and manufacturing method thereof

A technology of polycarbonate and a manufacturing method, applied in the field of automotive solar energy, can solve the problems of solar cell damage, brittle material fatigue, complicated process, etc., and achieve the effects of ensuring service life, good impact resistance, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

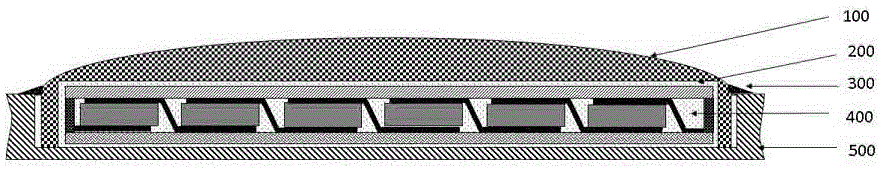

[0025] Such as figure 1 As shown, the polycarbonate-encapsulated solar roof of the present invention includes a polycarbonate shell 100 and a roof 500 with a mounting groove, and the outer surface of the polycarbonate shell 100 is set to adapt to the shape of the outer surface of the roof The curved surface of the polycarbonate shell 100 is provided with an installation cavity for installing the solar cell assembly 400. There is a plane in the installation cavity that can fit the solar cell assembly 400. The solar cell assembly 400 is placed in the installation cavity. The battery assembly 400 is combined with the plane of the installation cavity through the light-transmitting organic silica gel 200, and the polycarbonate shell 100 installed with the solar battery assembly is installed in the installation groove of the roof 500, and the top opening of the installation groove is connected with the polycarbonate shell. A sealing strip 300 is provided between the ester shells.

...

Embodiment 2

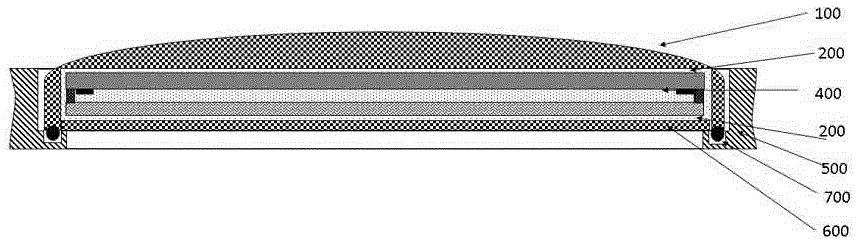

[0032] Such as figure 2 As shown, the sunroof of the polycarbonate-encapsulated solar roof of the present invention is based on Embodiment 1. Further, the installation groove of the roof is set as a through hole communicating with the vehicle body cavity, and the polycarbonate The bottom of the ester housing 100 is provided with a transparent bottom cover 600 for encapsulating the solar cell assembly 400, and a sealing ring 700 is provided between the bottom edge of the polycarbonate housing 100 and the edge contact portion of the roof installation groove. The component 400 is also bonded to the transparent bottom cover 600 through the light-transmitting organic silica gel 200 .

[0033] The transparent bottom cover 600 can be made of polycarbonate sheets transparent to visible light, or film materials such as coated polyethylene terephthalate (PET) or ETFE to make it transparent to visible light, UV blocking and infrared blocking ability.

[0034] Still further, a groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com