One-component silicone rubber for acrylic bonding and preparation method thereof

A silicone rubber, one-component technology, applied in the direction of adhesives, etc., can solve the problems of glue failure and low surface energy of acrylic, and achieve good weather resistance, environmental aging performance, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

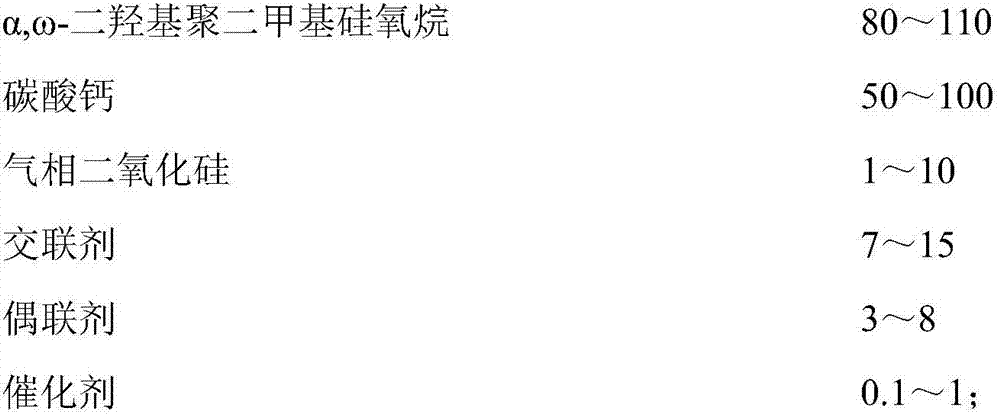

[0022] 1. In this embodiment, a single-component silicone rubber used for acrylic bonding is composed of raw materials in parts by weight:

[0023]

[0024] in:

[0025] Calcium carbonate is composed of heavy calcium carbonate by weight: light calcium carbonate=1: 1, and the average particle diameter is 1 μ m;

[0026] The cross-linking agent is methyl tributylketoxime silane in weight ratio: vinyl tributylketoxime base silane=7:1;

[0027] The coupling agent is highly active siloxane by weight: γ-aminopropyltriethoxysilane=1:4; wherein, the highly active siloxane is amino POSS by weight: isocyanatopropyltrimethoxysilane =2:1.

[0028] 2. The preparation method of the one-component silicone rubber used for acrylic bonding in this embodiment is as follows:

[0029] Stir and mix α, ω-dihydroxypolydimethylsiloxane, calcium carbonate, and fumed silica for 15 minutes, then continue to stir and mix for 30 minutes under the conditions of vacuum degree -0.08Mpa and stirring spee...

Embodiment 2

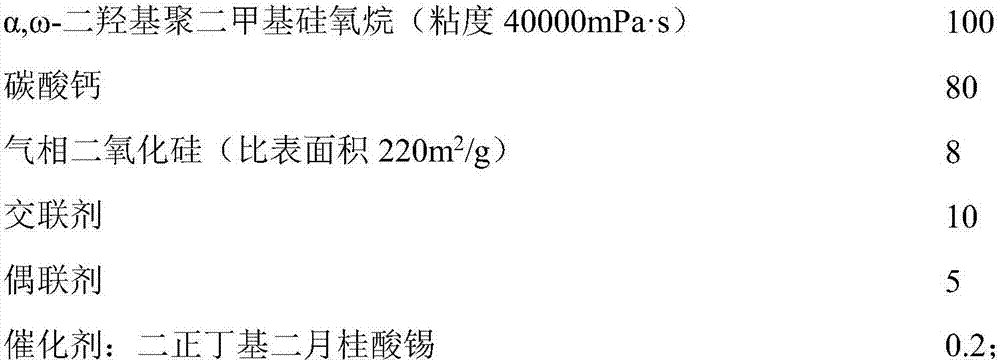

[0031] 1. In this embodiment, a single-component silicone rubber used for acrylic bonding is composed of raw materials in parts by weight:

[0032]

[0033]

[0034] in:

[0035] Calcium carbonate is composed of heavy calcium carbonate by weight: light calcium carbonate=2: 1, and the average particle diameter is 4 μ m;

[0036] The cross-linking agent is methyl tributylketoxime silane in weight ratio: vinyl tributylketoxime base silane=7:1;

[0037] The coupling agent is highly active siloxane by weight: γ-aminopropyl triethoxysilane=1:6; wherein, the highly active siloxane is amino POSS by weight: isocyanatopropyl trimethoxysilane = 3:1.

[0038] 2. The preparation method of the one-component silicone rubber used for acrylic bonding in this embodiment is as follows:

[0039] Stir and mix α,ω-dihydroxypolydimethylsiloxane, calcium carbonate, and fumed silica for 10 minutes, then continue to stir and mix for 40 minutes under the conditions of vacuum degree -0.09Mpa and...

Embodiment 3

[0041] 1. In this embodiment, a single-component silicone rubber used for acrylic bonding is composed of raw materials in parts by weight:

[0042]

[0043] in:

[0044] Calcium carbonate is composed of heavy calcium carbonate by weight: light calcium carbonate=2: 1, and the average particle diameter is 4 μ m;

[0045] The cross-linking agent is methyl tributylketoxime silane in weight ratio: vinyl tributylketoxime base silane=7:1;

[0046] The coupling agent is highly active siloxane by weight: γ-aminopropyl triethoxysilane=1:8; wherein, the highly active siloxane is amino POSS by weight: isocyanatopropyl trimethoxysilane =4:1.

[0047] 2. The preparation method of the one-component silicone rubber used for acrylic bonding in this embodiment is as follows:

[0048] Stir and mix α, ω-dihydroxypolydimethylsiloxane, calcium carbonate, and fumed silica for 20 minutes, then continue to stir and mix for 20 minutes at a vacuum degree of -0.08Mpa and a stirring speed of 40 Hz; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com