Environmental-aging-resistant polyolefin photovoltaic cable

A technology of photovoltaic cables and polyolefins, which is applied in the direction of insulated cables, power cables, cables, etc., can solve the problems that the internal insulation layer cannot withstand high temperature protection, the effect of anti-environmental aging is not ideal, and the overall structural strength of the cable is reduced. Anti-environmental aging, simple structure, and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

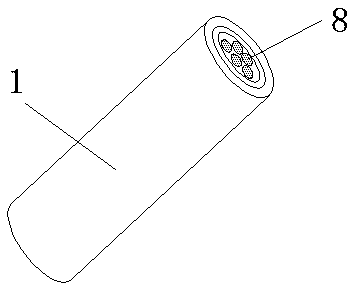

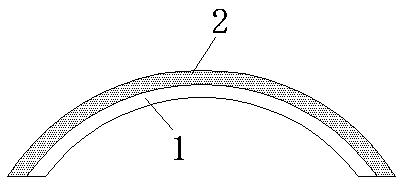

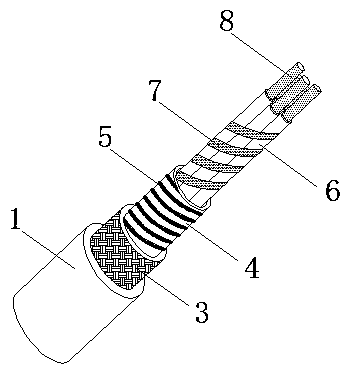

[0017] like Figure 1-3 As shown, an anti-environmental aging polyolefin photovoltaic cable includes a polyolefin jacket 1, the outer surface of the polyolefin jacket 1 is fixedly equipped with a polytetrafluoroethylene layer 2, and the inner surface of the polyolefin jacket 1 is fixedly installed with High temperature resistant braided sheath 3, the inner surface of said high temperature resistant braided sheath 3 is fixedly installed with insulating protective sheath 4, the outer surface of said insulating sheath 4 is wound and installed with support shaping steel wire 5, the inner surface of said insulating sheath 4 Five groups of copper core insulating jackets 6 are fixedly installed, and the outer surface of the copper core insulating jacket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com