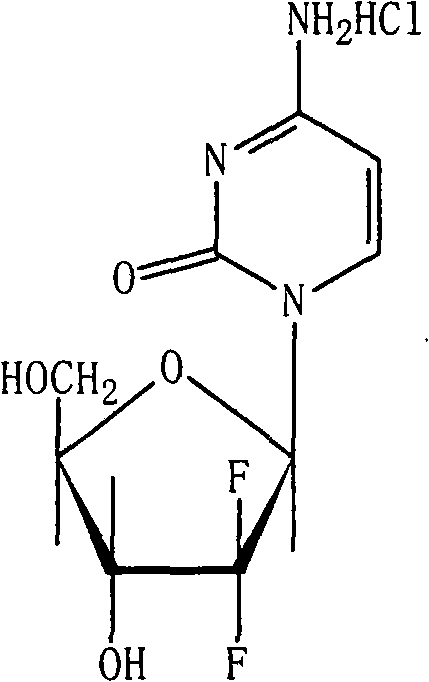

Gemcitabine hydrochloride lyophilized powder injection

A technology for gemcitabine hydrochloride and freeze-dried powder injection, which is applied in the field of gemcitabine hydrochloride freeze-dried powder for injection and its preparation, can solve the problems of lack of improvement, poor stability of gemcitabine hydrochloride, toxic and side effects, etc., and achieves considerable economic and social benefits, moisture drying Thorough, low levels of related substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

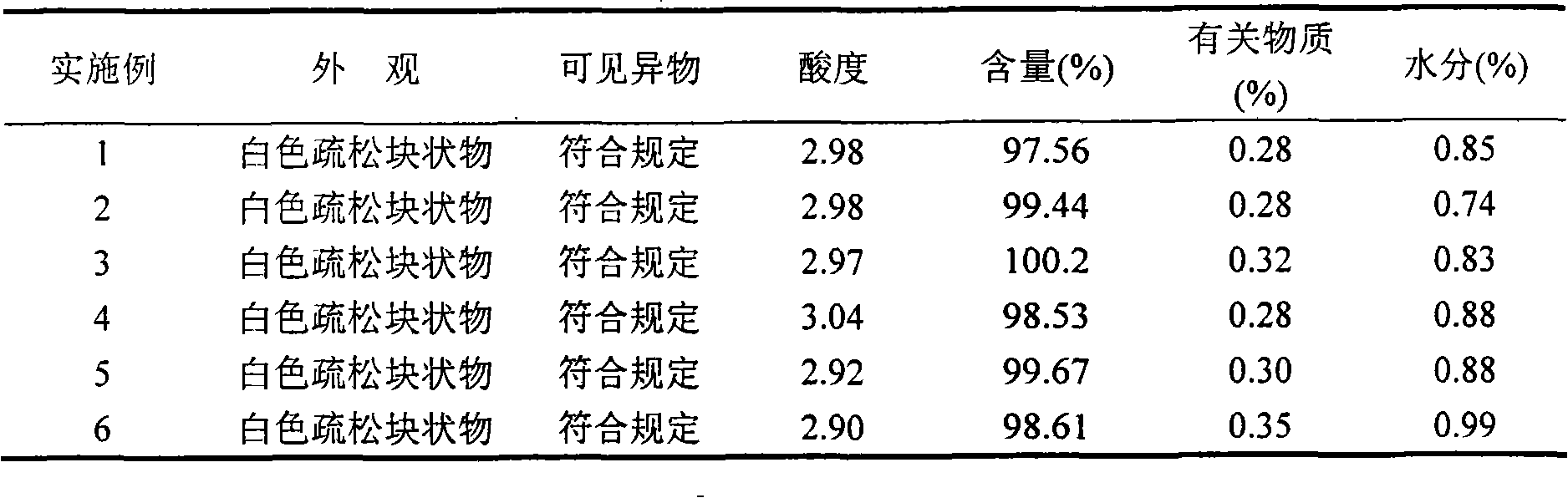

Embodiment 1

[0020] prescription

[0021] Gemcitabine Hydrochloride 228g

[0022] Mannitol 228g

[0023] Sodium acetate 22.8g

[0024] Add water for injection to 6000ml

[0025]

[0026] A total of 1000 bottles were made

[0027] Weigh mannitol and sodium acetate, add 80% water for injection, dissolve and stir evenly, then add gemcitabine hydrochloride, dissolve and stir evenly, adjust pH to 2.7 with 0.1mol / L hydrochloric acid or 0.1mol / L sodium hydroxide solution, After passing the intermediate inspection, add water for injection to make up to full volume. The solution was sent to the sterile room by a peristaltic pump, filtered through a 0.22 μm microporous membrane until it was clear, filled in 25 ml vials with a volume of 6 ml per bottle, partially plugged with butyl rubber stoppers, and placed in a plate. Put the sample to be freeze-dried in the freeze-drying box, close the box door, turn on the machine, turn on the circulation pump, compressor ...

Embodiment 2

[0029] prescription

[0030] Gemcitabine Hydrochloride 228g

[0031] Mannitol 114g

[0032] Sodium acetate 11.4g

[0033] Add water for injection to 6000ml

[0034]

[0035] A total of 1000 bottles were made

[0036] Weigh mannitol and sodium acetate, add 80% water for injection, dissolve and stir evenly, then add gemcitabine hydrochloride, dissolve and stir evenly, adjust pH to 3.3 with 0.1mol / L hydrochloric acid or 0.1mol / L sodium hydroxide solution, After passing the intermediate inspection, add water for injection to make up to full volume. The solution was sent to the sterile room by a peristaltic pump, filtered through a 0.22 μm microporous membrane until it was clear, filled in 25 ml vials with a volume of 6 ml per bottle, partially plugged with butyl rubber stoppers, and placed in a plate. Put the sample to be freeze-dried in the freeze-drying box, close the box door, turn on the machine, turn on the circulation pump, compressor and pla...

Embodiment 3

[0038] prescription

[0039] Gemcitabine Hydrochloride 228g

[0040] Mannitol 1140g

[0041] Sodium acetate 11.4g

[0042] Add water for injection to 6000ml

[0043]

[0044] A total of 1000 bottles were made

[0045]Weigh mannitol and sodium acetate, add 80% water for injection, dissolve and stir evenly, then add gemcitabine hydrochloride, dissolve and stir evenly, adjust pH to 3.0 with 0.1mol / L hydrochloric acid or 0.1mol / L sodium hydroxide solution, After passing the intermediate inspection, add water for injection to make up to full volume. The solution was sent to the sterile room by a peristaltic pump, filtered through a 0.22 μm microporous membrane until it was clear, filled in 25 ml vials with a volume of 6 ml per bottle, partially plugged with butyl rubber stoppers, and placed in a plate. Put the sample to be freeze-dried in the freeze-drying box, close the box door, turn on the machine, turn on the circulation pump, compressor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com