Environment-friendly rubber plasticizing homogenizing agent and preparation method thereof

A technology of rubber plasticizing and homogenizing agent, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of easy bubbling and overflow, harsh reaction conditions, long reaction time, etc. The effect of fewer steps and shorter reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

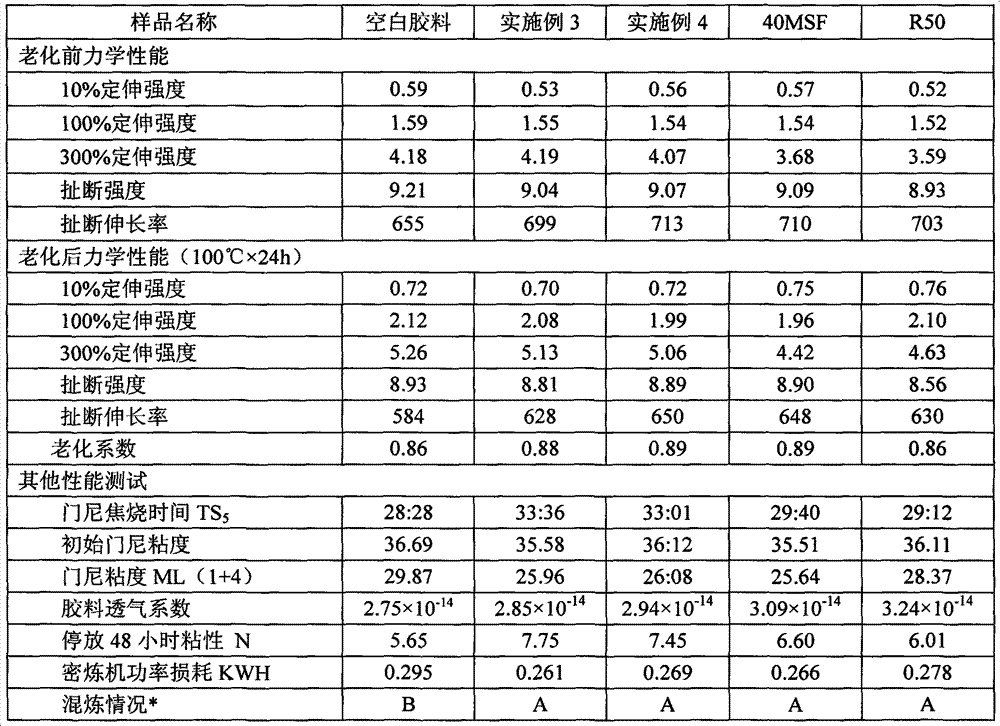

Examples

Embodiment 1

[0029] Add 90 parts of treated heavy traffic petroleum asphalt, 10 parts of C9 petroleum resin, and 5 parts of oxalic acid into the reactor, raise the temperature to 175°C and stir evenly, then gradually add 10 parts of polyethylene glycol with a molecular weight of 400 to the above system , keeping at 160°C for 1 hour, and keeping the reaction for 60 minutes under the condition of vacuum degree -0.1MPa to prepare a rubber plasticizer homogenizer.

Embodiment 2

[0031] Add 70 parts of treated heavy traffic petroleum asphalt, 30 parts of coumarone resin, and 3 parts of p-toluenesulfonic acid into the reactor, raise the temperature to 110°C and stir evenly, then gradually add 3 parts of paraformaldehyde to the above system, Keep the reaction at 110°C for 1 hour, and keep it under the condition of vacuum degree -0.1MPa for 45 minutes to prepare a rubber plasticizer homogenizer.

Embodiment 3

[0033] Add 85 parts of treated heavy traffic petroleum asphalt, 3 parts of C5 petroleum resin, 12 parts of C9 petroleum resin, 2 parts of p-toluenesulfonic acid, and 8 parts of 36.5% hydrochloric acid into the reactor, heat up to 130°C and stir evenly, and then add Gradually add 5 parts of paraformaldehyde to the above system, keep the reaction at 130°C for 0.5 hours, and keep it for 15 minutes under the condition of vacuum degree -0.1MPa to prepare a rubber plasticizer homogenizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com