Rust proof coating for machinery equipment and preparation method thereof

A technology for anti-rust coatings and mechanical equipment, applied in anti-corrosion coatings, asphalt coatings, coatings, etc., can solve the problems of low anti-rust performance and easy wear of coatings, achieve excellent anti-rust and wear-resistant functions, and reduce environmental pollution , The effect of not easy to peel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

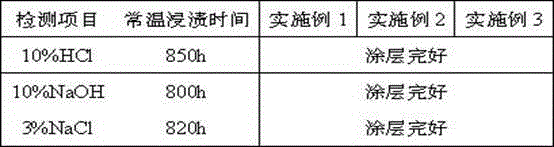

Examples

Embodiment 1

[0009] This embodiment provides an antirust coating for mechanical equipment, which contains the following components in parts by mass: 30 parts of coal tar, 8 parts of maleic anhydride, 3 parts of modified phenolic resin, 10 parts of barium borate, 8 parts of molybdenum dioxide 7 parts of aluminum tripolyphosphate, 1 part of diatomaceous earth, 1 part of kaolin, 1 part of light calcium carbonate, 4 parts of propylene glycol, 0.6 parts of lead naphthenate, and 15 parts of deionized water.

[0010] The preparation steps of an antirust coating for mechanical equipment are as follows: add coal tar and maleic anhydride to a three-necked flask equipped with a condenser tube and a thermometer, raise the temperature to 200°C, keep it warm for 3 hours, then add modified phenolic resin, and heat up To 230°C, keep warm for 1h, then cool down to 80°C, add propylene glycol, continue to cool down to 40°C, adjust the pH to 7 with ammonia water, then add 1 / 2 mass part of deionized water, mix ...

Embodiment 2

[0012] This embodiment provides an antirust coating for mechanical equipment, which contains the following components in parts by mass: 35 parts of coal tar, 10 parts of maleic anhydride, 4 parts of modified phenolic resin, 14 parts of barium borate, and 10 parts of molybdenum dioxide. 10 parts of aluminum tripolyphosphate, 1.5 parts of diatomaceous earth, 1.5 parts of kaolin, 1.5 parts of light calcium carbonate, 5 parts of propylene glycol, 0.8 parts of lead naphthenate, and 20 parts of deionized water.

[0013] The preparation steps of an antirust paint for mechanical equipment are as follows: add coal tar and maleic anhydride to a three-necked flask equipped with a condenser tube and a thermometer, raise the temperature to 210°C, keep it warm for 3 hours, then add modified phenolic resin, and heat up to 240°C, keep warm for 1 hour, then cool down to 90°C, add propylene glycol, continue to cool down to 50°C, adjust the pH to 7 with ammonia water, then add 1 / 2 mass part of de...

Embodiment 3

[0015] This embodiment provides an antirust coating for mechanical equipment, which contains the following components in parts by mass: 40 parts of coal tar, 12 parts of maleic anhydride, 5 parts of modified phenolic resin, 18 parts of barium borate, and 13 parts of molybdenum dioxide. 12 parts of aluminum tripolyphosphate, 2.5 parts of diatomaceous earth, 2.5 parts of kaolin, 2.5 parts of light calcium carbonate, 7 parts of propylene glycol, 1 part of lead naphthenate, and 25 parts of deionized water.

[0016] The preparation steps of an antirust paint for mechanical equipment are as follows: add coal tar and maleic anhydride to a three-necked flask equipped with a condenser tube and a thermometer, raise the temperature to 220 ° C, keep it warm for 3 hours, then add modified phenolic resin, and heat up to 250°C, keep warm for 1h, then cool down to 100°C, add propylene glycol, continue to cool down to 60°C, adjust the pH to 8 with ammonia water, then add 1 / 2 mass part of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com